Basic base for installations that generate electricity with electromagnets was developed by the British experimenter and physicist Michael Faraday in 1831, which then built the Faraday disk, which is one of the first generators. After that, the electric generators were constantly improved within one and a half. Asynchronous and synchronous alternators, one and three-phase, without inverter control and with it were created. What is the difference between all these types?

Synchronous generators

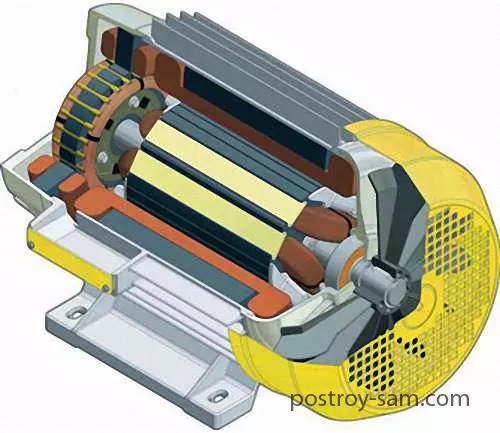

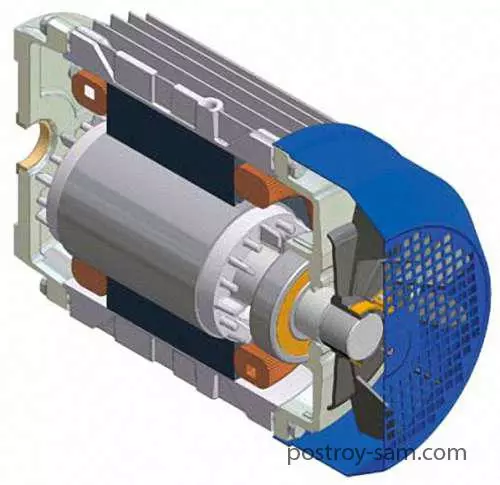

In a synchronous alternator, electricity is made with the coincidence of the frequency of rotation of the stator and the rotor. The electromotive force or EMF is created when the field formed by the magnetic poles of the rotor crosses the starting winding. In such a generator, the rotor is either a permanent magnet or an electromagnet that has a number of multiple poles two. A two-pole rotor, which has a rotational speed of 3000 rpm, is installed in the backup generators, and in the main generators that produce electricity around the clock, the rotor rotates with a frequency of 1500 rpm.

After starting the synchronous generator, the rotor forms a rather weak magnetic field, but gradually the amount of its revolutions increases and EMF increases. At the output, the stability of the voltage is controlled using the automatic adjustment unit (AVR), which changes the magnetic field during the flow of voltage on the rotor from the excitation winding. When operating synchronous generators, the "Anchor Reaction" may occur, that is, when the inductive load is activated, the generator is demaging and the voltage falls. And in the case when the capacitive load is supplied, on the contrary, the generator is appropriate and the voltage grows.

The advantage of synchronous generators is the stable voltage at the output, but their disadvantage is the tendency to overloads, which are possible when the loads grow and exceed the valid level, that is, the current in the rotary winding is excessively incremented by the AVR unit.

The synchronous generator is capable of briefly produce on issuing such a current that may exceed the nominal value several times. Since some electrical appliances that include electric motors, compressors, pumps and some others, an increased starting current is required, and they have an increased load on the network, the best source of both the main and backup feeds will be just alternators.

Article on the topic: Installation of MDF panels on the ceiling with kleimers

Asynchronous generators

Rotation of the rotor in such generators a little ahead of turnover magnetic field, which is created by the stator. Such electric generators include rotors with two types of winding - short-circuited and phase. In an asynchronous generator, the principle of operation is exactly the same as in its synchronous analogue - the stator creates a magnetic field on the auxiliary winding, which is then transmitted by the Rotor and forms on the stator winding of the EMF. But the difference lies in the fact that the frequency with which the magnetic field rotates is unchanged, that is, its adjustment is invalid. That is why the frequency of electric current, which is produced by an alternator, and the voltage, have a direct connection with the rotor revolutions, which in turn depend on the stable operation of the drive motor of the electric generator.

Asynchronous alternators have high protection from the actions from the outside and are quite small-sensitive to short circuits, so that they are great for welding machines. These generators are also well suited for substituting devices that have an ohmic (active) load, which are transformed by almost all electricity supplied by them, to work - computers, lighting lamps, kitchenware, heaters, etc.

High reactive (starting) load, which occurs when turned on, for example, pumping equipment, lasts about a second, but the electric generator must withstand it. And this is what - we assume that you need to move a heavy cart, which is installed on the horizontal surface. In order to move the trolley, it is necessary to make much more effort, which is needed in order to maintain its movement. It is the same situation that occurs when the refrigerator compressor is launched or split-systems, electric motors and any pumps, therefore, only the synchronous electrical generator can cope with it.

The reactive loads in the central power grid are compensated with chokes or capacitors, as well as using a specially increased cross section of electrical cables and transformers.

Article on the topic: The draft floor do it yourself: how to prepare lags and lay the boards?

The asynchronous alternator has a significant drawback - from not capable of withstanding increased loads. But, despite this, it is easier to design and cheaper than synchronous analog. In addition, asynchronous electric generators have a closed design, which is able to provide them with good protection against moisture and external pollution.

Three phase and single-phase generator

Some people are convinced that a single-phase electricity generator is worse than three-phase. The logic of those who do not understand the electricity is easy to understand - one phase is less than three, therefore worse. In fact, choose between three- and single-phase power supply must be based on the needs of end users.An electric generator that has three phases is not needed to feed three groups of single-phase consumers, and in order to feed three-phase devices.

It happens that the layout of three-phase input in the house is performed on single-phase groups, but it is advantageous to do not tenants, but electricians, because for this you need a very expensive protection of the power system, and its installation is very expensive. Almost all modern household appliances are single-phase, and three-phase were old models of electric motors and electric stoves.

Three-phase electric motors have one significant disadvantage - with the power of the alternator, for example, 10 kW, the power of each phase will be 3.3 kW. Among the phases, the maximum possible offset of the power load may not exceed 25% of the nominal, which is 1/3 of the total generator power. Based on this, a single-phase generator having a power of 4.5 kW will be more powerful than a three-phase generator by 10 kW.

Inverter generator

The inverter alternator has an electronic control unit that is able to ensure the production of excellent quality electricity, with a lack of any voltage drops. Inverter alternators are excellent for nutrition of such consumers who need only in nominal voltage.

An inverter control system for a synchronous alternator is established and acts in three steps: produces voltage with a frequency of 20 Hz; Then it forms a permanent current of 12 V; Further, the direct current is converted to a variable nominal having a frequency of 50 Hz.

Inverter generators are divided into three types of pulsed output voltage:

- For the cheapest models, a rectangular impetus is characterized. Such models can only feed building power tools. This type of inverters is almost not sold, as it has low popularity and very limited opportunities.

- The generators of the average price zone can provide a trapezoidal impulse. This allows them to feed rather complex household electrical appliances, such as refrigerator. But for the most sensitive technology, such quality voltage is often insufficient.

- With a sinusoidal impulse, the best conditions for the work of any devices are created - from the most simple to the most difficult. The sinusoidal voltage has stable characteristics and accurately complies with all the parameters of electricity, which is supplied by central electrical networks. The cost of such inverters is much higher than that of two other types.

Article on the topic: Decoration of ceilings by plasterboard with their own hands (photo and video)

Advantages of inverter generators:

- much smaller weight and sizes, if compared with simple generators of the same power;

- Less noise during operation, which is achieved due to the fact that the rotor speed changes;

- Very small fuel consumption, which is achieved by electronic control of the electricity generation process. The generator produces such a number of energy that is currently required to all consumers, and its performance decreases or increases with the appropriate decrease or increase in the number of consumers;

- Since they are based on a synchronous alternator, inverters can briefly supply high-speed energy-intensive equipment. In addition, in some models of inverter generators there is a "overload mode" function, in which the inverter can produce power by 50% more than the nominal. But this mode can act approximately 20-30 minutes;

- Good working on failure - about 3 thousand hours.

Disadvantages:

- The maximum continuous operation is 8 hours;

- have a higher cost compared to non-inverter analogues of the same power;

- The electronic control unit is quite sensitive, and its repair is quite expensive;

- The maximum power in the generators of this type is 7.2 kW, and there are no models that have more power.

conclusions

All the above types of generators, except inverter, can be used not only in low-power consumer models of power plants, but also in large generator systems that produce electricity megawatts.