If you go to the furniture store, then a wide range of different models of wooden furniture will be thrown into the eyes. Beautiful chairs are a lot: ranging from stools and ending with elite models. However, such beauty requires large cash costs. Therefore, to decorate the interior of the room, you can create a chair from wood with your own hands. To make it, you need to have certain materials and tools.

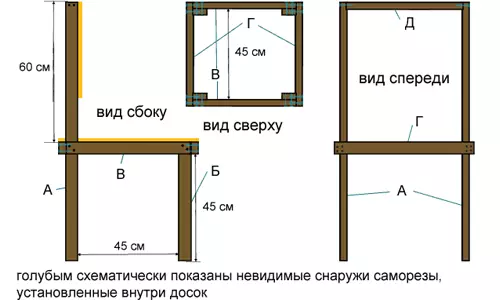

The dimensions of the wooden chair and the place of attachment of the self-tapping screws.

There are different methods allowing you to make a chair with your own hands. Choosing a way, you need to be guided by style, as well as its purpose. Work should begin with a drawing of a future design, where all the dimensions of the parts must be indicated, their number necessary for the work of the materials. The success of the work depends on the quality of the drawing.

Necessary materials and tools

When you need to make a chair with the help of a tree with your own hands, you need to use wood only hardwood. The main material is considered to be wood, well dried and having no bitch. For the manufacture of furniture usually choose:

- pine;

- oak;

- beech.

It is very hard to treat an oak or beech, but the furniture from such a tree with their own hands is solid and reliable. To make a chair, you need to have:

- two bars;

- dense upholstery fabric;

- foam rubber from which the seat is done;

- boards of different sizes;

- sandpaper;

- Furniture glue;

- Saws.

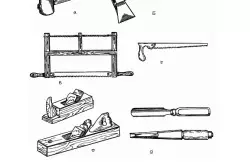

Tools for making a wooden chair.

Brussia can be bought in the construction market. Then they need to be processed so that they are absolutely smooth. To do this, they are grinding to obtain roughness. First, the timber grinds the shallow sandpaper (fits №100). The final brilliance of Brusa will give the sandpaper №220.

Any job in order to make a chair from the tree with their own hands, requires tools:

- sandpaper;

- stapler;

- hacksaw;

- Conductors,

- Wooden mystery;

- chisel;

- plane.

Article on the topic: Is it possible to connect a warm floor without thermostat

Technology and work features

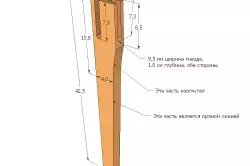

How to make a chair? First you need to prepare two bar. The bars of the rear legs should have dimensions of 800x40x60. The front legs, the size of the bars must be equal to 440x40x40 mm.

In the bars, grooves intended for prodrice and bases (both longitudinal and transverse) are cut down. All grooves must be made on the same level. To achieve this, you need to lay them together, ends of the legs must necessarily coincide. Then placed the place where the grooves will be made. Their dimensions are 20x40x15 mm. The inner part of the groove should have an indentation from the inside of the leg. Typically takes 10 mm.

For fastening the bases, the legs must have grooves. In each foot there should be two. The manufacture of grooves is performed at the corresponding ends of the legs. After graduation, the base will have a form of a rectangle. On each vertex the leg will be installed. For the manufacture of grooves the chisel is used. Then the grooves are released from chips that have fallen in them in the manufacture.

Scheme of chair legs.

Rear legs need to be slightly correcting. To this end, along the entire length of the leg, ranging from the groove, made at the top, and ending with the lower groove, the face is constrained. The result is a smooth transition, the size should be reduced and equal to 40 mm.

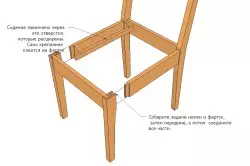

After the manufacture of legs are made two proders, two longitudinal bases are harvested. For this purpose, four brus are made with dimensions of 350x40x40 mm. Each end must have a mark for spikes. The spikes are made by a chisel from sliced blanks.

Sizes of spikes should be made according to the size of the grooves. They must be tight in the groove. The presence of backlash is prohibited.

Then two brus are harvested with dimensions of 420x40x40 mm. They are needed for the manufacture of transverse base. For such bars, spikes are also cut.

The next operation will be the manufacturer of the back. It is better made of edged board. Dishes dimensions - 420x80x100 mm. In the rear legs displaced the grooves of the desired width. The backrest is inserted into them.

Article on the topic: The width of the entrance door to the house: standards, calculations, measurements

The fastening of the seating is carried out by self-drawing, and they should be screwed from below. To make it easier to twist the screws and give the chair additional rigidity, special discolutions are inserted between the bases.

To make a beautiful appearance, the legs of the chair must be rounded and then chop up. The same operation must be carried out with the basis. Fully finished parts need to be coated with furniture varnish, and then subjected to polishing.

One of the last steps is the manufacture of a soft seat. A seat is peaked out of a sheet of thick plywood, the billet of the foam rubber corresponding to the form is also made. When the chair is made, approximately 15 cm are retreating from the edge. Then the Phaneur turns along with the foam rubber to the furniture cloth.

The material is fixed by the stapler on the reverse side of the base.

Chair assembly scheme.

Experience shows that when a tree stool is done with their own hands, you should always remember about the environment. The fact is that the coating varnish causes a very strong unpleasant smell. Neighbors will not be delighted. Therefore, all painting work is best done outside the apartment. For example, in a garage or shed.

Recently, special varnishes appeared, the basis of which is water. They do not smell.

From the harvested ladded parts is assembling the chair. The spikes are covered with glue and inserted into the grooves. All items are knocked down by a wooden Cyan.

If you use a metal hammer, then its shock part must be closed with a soft cloth. Otherwise, you can damage the lacquer coating. The fastening of the seating and the back is carried out by screws.

Folding chairs: manufacturing nuances

Make a folding chair from the tree with their own hands will be able to any craftsman. This will require much less time to compare with the manufacture of ordinary tobupere.To work you need to stockp wood. Front legs and backs are made of shield. These details will be able to move. The rear legs are made of wooden bars. Thin rails are nourished on the back. As a material for seating, you can take a phaneer, covered with dense furniture cloth. To fix the product in the desired position, you need to make several spikes on the shield. Steel pins will be useful for fastening the base.

Article on the topic: how to make endand on the roof

To horizontal fixation of the seating and installing a shield under the tilt, make spikes. Fixation of seats is carried out by two steel pins.

Braided Chair: Recommendations

Does not cause special difficulty production of a wicker chair. To perform work, you must have:

- braid;

- nails;

- bars;

- hacksaw;

- self-tapping screw;

- a hammer;

- Danish oil;

- drill;

- sandpaper.

The length of the legs is postponed. Four brus with 18x4x14 cm dimensions are prepared.

Grooves are made in those places where the connection will be held and fastened. For bars to be smooth, they are grinding sandpaper.

Then a braided chair is going. Assembly works begin with the fastening of the legs. Screws are screwed.

Danish oil is applied to the collected frame. If it is not, then the replacement can be furnished lacquer.

The final operation will be weaving belts. Usually, for this purpose, long straps made of leather are used.