In order to make a rocking chair with your own hands, you will need an easy set of materials and tools. Often, prices for such products in stores are forced to postpone the purchase for a long time, but for a person having basic woodworking skills, there are no such problems.

The rocking chair can be made from various materials, but the most common tree is.

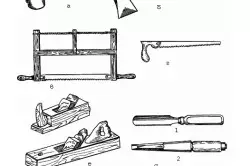

The rocking chair is relatively simple, the following tools will be required to work:

- Lobzik electric;

- Schlifmashinka;

- set of different nozzles;

- hand mill for edge processing;

- screwdriver;

- Tree drills;

- painting brushes;

- roller;

- roulette;

- pencil;

- Corolnic;

- Eurofer;

- Bar;

- confirmates;

- Saws.

Tools for making rocking chair.

Brucks on the finished product will need to take with the calculation that they will need at least 35 pieces for the manufacture of chair chairs. The length depends on the desired width of the rocking chairs, as it will differ significantly in single and double models.

The choice of wood affects what product will turn out. Phaneru is much easier to get, it is easy to work with her, they serve the products made from Eurofaneners long enough. But in order to make furniture for many years, it is better to stop your choice on wood. Pine is not too highly appreciated, but is a solid tree sufficiently. And if the issue of saving funds in the last place, you can choose a larch or oak.

Materials for rocking chair

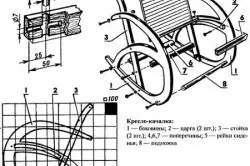

First you need to prepare the drawing, paying special attention to the side view. From the leaf of Eurofaneners according to the drawing, then 2 curved preforms are cut out 2. Both must be completely symmetrical so that when the chair moves, it does not have difficulty. It is more convenient to first draw contours on a sheet of paper, then cut and circle on plywood sheets.

Article on the topic: How beautiful to arrange the walls with curtains

To make a chair a rocking chair, the sidewalls are most convenient to cut the jigsaw. If there is no electric, you can use manual.

Carved forms require grinding, which is done using grinders. When working this tool, special attention should be paid to the end face of sheets. After that, in order to make the chair even better, remove the chammere with the help of a hand mill.

The sidewalls are processed additionally, catching the olive to the ends after the first grinding. When the layer of olifa dries, the surface is vague. When applied and as the first layer of varnish is drying, the surface of the plywood will become very rough, since small fibers of wood rise from this procedure. Therefore, when the first layer of lacquer dries out, the phaneer is required to polish and turn the lacquer again.

Chair chairs rocking from plywood.

The next step in order to make a rocking chair with your own hands, is the manufacture of the Tsarg. They need to be cut out of the remaining plywood. In already cut sidewalls, marked to attaching the CARG, and the new parts are subjected to the same processing with grinding, oil and varnish. The exact places of attachment of the CARG are determined depending on the shape of the sidewall, but they must be located in the middle and at both ends.

In order for the tags to be even, they first make them on one sidewall, after which the sidewalls are folded and tightened by clamps so that in the process of work they are not shifted. Drill is taken and end-cutting holes through both sidewalls. Tsargi are applied and marked with a pencil, as it also needs to drill holes. Details fasten with confirmates.

For the manufacture of bars, first make one as a template. It serves mainly in order to make in all subsequent symmetric holes. On average, the rocking chair of bars requires 140 pieces. The block pattern is taken and on it a pencil from the outside, the places of holes are noted, which will be attached to it to the frame from the EuroFaneners. Drill through holes. After that, a plywood is applied to the bar from which its outline is cut and the holes are made. Having attached such a plywood contour to the next bars, you can immediately drill holes in them without posting pre-each.

Article on the topic: Safe expansion of openings in the bearing walls

Assembling chairs Rocking

Bruks to the frame are fastened with the help of self-tapping screws. The distance between the bars is recommended to do from 1 to 1.5 cm, and the self-screws need to screw the flush so that they do not protrude outside. The protruding fasteners in most cases spoils the clothes of those sitting in the chair of the people, you need to make the surface smooth.Marking for all bars is not recommended immediately. It is much more convenient to fix them with groups of 5-6 pieces and pre-markings to do on the same amount. After completion work, all self-tapping screws are required to be primed and coated with an antiseptic agent. After assembly, the furniture is still covered with varnish for greater strength.

How to make a rocking chair with your own hands: an easy way

A simple way is to cut the legs in an ordinary chair, so that the center of gravity becomes lower and when there was no bigger risk to fall. The residues of the legs are required to scout two symmetric arcs from the EuroFaneners, on which the swing will later and will be carried out.

Arcs for such an armchair are manufactured using a bent-adhesive method. From plywood with a thickness of about 8 mm, they are cut off with the help of the panel of the workpiece of the desired size. They are brought to the desired form with the assistance of the reysmaus. The curved shape of the desired length can be made from any submitted means.

The first lamellas is punctured, the second one is stacked on it. Thus, the desired number of lamellas is glued, and they are attached to the curved shape. The glue must dry, after which the lamellas must save the required curved shape. The dryer is treated with grinders again, then paint in the same color as a chair.

Most often, armrests on the chairs are absent, they have to add themselves.

They do not carry a big load, so for their manufacture, you can take a strip of 10 cm thick and attach them to the legs with bolts. To these racks, the armrest is attached with the help of a thickening compound. It is grinding, covered with a verse or varnish, they grind and apply the second and third layers. The rocking chair of any type wins, if you cover it with a cloth and make a similarity of pillow with foam rubber and synthesis.

Article on the topic: What is the shelf life at the wallpaper glue