In the country area or in the courtyard of a private house, a large table is simply necessary. In the summer, you can sit behind it in a family circle or surrounded by friends, enjoying the evening coolness. Buy a ready-made table for installing it in the yard, not an option, since such a product will quickly come into disrepair from the rain. It remains only to make it yourself.

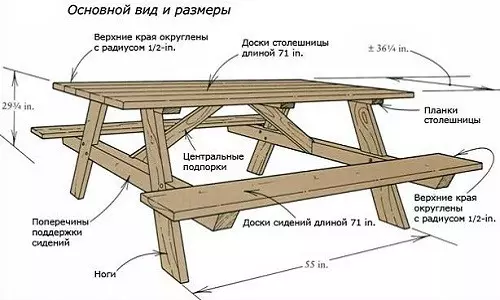

Desk pattern from boards.

Make a table of logs with your own hands, and such a design will serve for many years. You can use both boards. Below will be considered both options. The manufacturer's scheme is quite simple, and make such furniture can anyone who knows how to keep the plans in the hands and score nails.

Production of a table of logs do it yourself

This will require:

- logs without bark;

- Bar;

- Plancock and Fuganok;

- hammer and nails;

- shovel;

- bitumen, olife and oil paint.

Drawing of a wooden table.

You need to choose smooth logs with a minimum number of bitch. If it is possible to use the sawmill, you can cut them along.

If there is no such possibility, then half the logs need to be simply eager. Of course, there will be a lot of waste, but one part must be smooth. On the surface you need to walk by Fugansky to make it as smooth as possible.

The logs need to be located near and combine the bar between them from the bottom. It turns out a tabletop. The bar is nailed with nails across the logs, along the edges of the table top and in the middle. It is necessary to choose from the bottom side, from the side of the bar, selecting such a length of nails so that they do not pass through the tabletop. Well, the upper part of the table is ready, it remains only to install it in the yard.

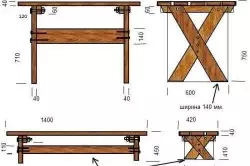

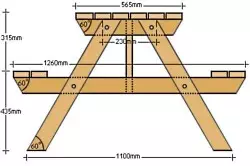

Dark Table Drawing Benches

To do this, 4 logs are laughed in the ground to a depth of at least half a meter. Those ends of the logs that will be in the ground are recommended to deceive bitumen to protect the tree from rotting. After the pillars are discharged, the countertop is installed on them and nailed. Hats nails should be dried in wood.

Article on the topic: How to make a playground yourself: 70 photos of real buildings

The finished product is recommended to proliferate and paint the oil paint, which reliably protect the tree from atmospheric precipitation.

But this is not the only option. For example, instead of logs for countertops, you can use boards, and in the manufacture of legs, it uses trimming logs, while engaging them with each other.

How to make the table from the boards with their own hands?

Tools for the manufacture of tables from boards.

Such a product is easier, and it can be done portable, in contrast to the previous design.

For the manufacture, good outrageous boards are taken and knocked down in the worktop. You can use fine-quality floorboards.

Compounds of the "comb-groove" type will make the maximum smooth surface, which will make such furniture even more attractive.

At first, a rectangular or square frame is knocked out from the bar on which the boards will be stuffed. If there is no experience and there is no possibility to make spike connections, you can use metal corners. Boards are stuffed on the frame. If the boards are usual, then nails should be sown from below, following the tabletop so that they do not pass through the worktop.

Wooden table manufacturing stages.

If the floorboards are used, it will be more convenient to score nails from above, as it is necessary that the comb entered into the groove. The boards are pressed to each other, and the nails are driven at an angle, additionally pressing them. If you do everything correctly, it turns out a flat surface of the table, without cracks. If nails are clogged on top, then their hats should be dried in wood, and holes to sharpen before painting.

Now it remains only to fasten the legs - and the product is ready. The legs are made of wooden bars, which are attached to the frame using metal corners. Such a table of boards has a much smaller weight than made of logs. It can be moved from place to place, install near summer kitchen or in a garden gazebo.

To such desks, you can make your own hands benches or stools that will approach design.

There are many options for the manufacture of such garden furniture. Each craftsman uses his fantasy so that his brainchild looks original and at the same time comfortable.

Article on the topic: Painting lining on the loggia and balcony