Under the seeming similarity, accumulative water heaters may have quite significant differences. Depending on the materials and structural features used, some water heaters can be more reliable than others. What characteristics are needed for high-quality boiler?

Cumulative water heaters help keep any amount of hot water. Their difference only in size: the greater the size, the longer the water heats up.

Execution of internal container

Characteristics of working conditions

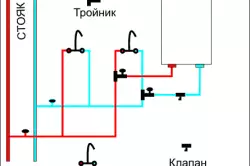

Connecting a cumulative water heater.

All accumulative water heaters have an internal container or tank. Let's deal with what tank should have a reliable heater. Cold water incoming in it already has an overpressure of 2.5..3.5 bar. All that is above must be cut off using the pressure regulator installed at the entrance to the apartment.

Cold water for the correct layered distribution is supplied to the water heater below. In order, when the water is disconnected, it does not flow out of the tank, the check valve is installed on the input to it. Waterproof control is carried out using mixers on instruments. Water with increasing temperature expands. Water heating in a closed volume causes a significant increase in pressure, which is perceived by the walls of the tank.

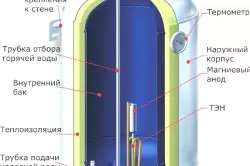

Device of the accumulative water heater.

Pressure growth before emergency values prevent 2 constructive solutions. First, it is an airbag in the upper part of the tank, which is about 10% of the capacity of the tank. Air, compressing, compensates for the temperature expansion of water. Secondly, with an increase in pressure inside the tank over the alarm, a reset valve will work. The trigger threshold of this valve varies in the range of 5.5-7.5 bar.

This is quite significant pressure, and the water heater must withstand it. When he is new, no problems arise, but over time they are possible. The fact is that the heaters have tanks made of steel, and it is subject to corrosion. The water heater warms ordinary water tap water without any special training. The substances dissolved in it give it the properties of the electrolyte. As a result, corrosion develops inside the tank.

Galvanic corrosion arises due to the difference in potentials of various metals, of which the water heater and fittings are made at its inlet and outlet. When different pairs of metals are in contact with the electrolyte, the metal is oxidized with the largest negative potential. It has become equal to -0.63 V, the copper -0.2 B, which means that steel will rust in this pair. To minimize this type of corrosion, it is worth using steel or plastic fittings.

Article on the topic: Ceiling panels in the room: cheap and beautiful

Electrolytic corrosion is developing even in case of contact through the electrolyte of metals with the same potential in the presence of an electric field. It is the result of the presence of uncontrolled electrical currents. For example, in the case of leaks on the ground. As a result of electrolytic corrosion, the metal with a large negative charge gives into electrolyte free ions and corrosive.

Internal Tank Protection Methods

What activities include manufacturers to increase the durability of the heater tank? First, it is the coating of the inner surface with protective coatings. Secondly, placement inside the metal tank with a large negative potential. This is usually magnesium, which is called sacrificial cathode, and such protection cathode. Thirdly, the manufacture of stainless steel tanks.

Emalization is used as a protective coating.

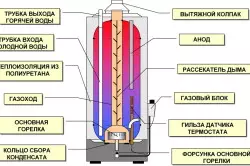

Gas storage water heater.

Cumulative water heaters with enameled coating are relatively cheap, but rather durable. The service life of such a coating is highly dependent on the degree of adhesion of the coating to the base, its thickness and compliance of the coefficient of temperature expansion of the enamel used relative to this indicator for steel. Elasticity and resistance to the formation of cracks are also important.

Manufacturers use different types of coatings. The most common options are glass fluoror or glass email. They reliably protect the steel walls of the tank, but only until there are cracks from permanent expansion and compression when temperatures drops. These materials are rather fragile and can be damaged at the slightest shocks, so water heaters with an enamel coating of the inner surface of the tank based on silicates require exclusively accurate circulation.

Most manufacturers declare that it is they who use that unique recipe for making enamel, which makes their water heater most durable. Various additives are used, improving enamel properties.

For example, there are proposals for water heaters with titanium enamel. This means that a few percent of titanium has been added to the glass email. This material improves the hygienic properties of the tank and increases the resistance of the enamel to most aggressive environments. However, the addition of titanium does not enamel more resistant to cracking, and in proportion more than 4% even increases its fragility.

Installation scheme of the accumulative water heater.

Carefully on the strength of the tank and its stability to corrosion affects the thickness of the steel sheet, which was used during its manufacture. The cheapest and fragile tanks are made from a sheet with a thickness of 1.5 mm, a sheet of 2 mm is used in the middle price category, and the most expensive tanks have a wall thickness of 2.5 mm or more. Water heater with a normal thickness of the tank walls cannot be too easy. The heavier water heater, the more durable.

Article on the topic: DECOR TABLE DIY: Decoupage, cracker, painting

Sometimes it seemed the most cardinal method to prevent corrosion. The walls of the tank are made of stainless steel. It can really significantly increase the service life of the heater. But the thing is that the tank cannot be made of a single sheet of steel and have to apply welding.

In order for the anti-corrosion properties of stainless steel not deteriorated during the welding process, special expensive types of stainless steel and special welding technologies should be applied. European manufacturers rarely go to it, the exception is some expensive water heaters from the Scandinavian manufacturers.

There are many relatively inexpensive products with stainless steel tanks. Almost all of them issued from Chinese components, and the service life of such products is not too much higher than this indicator for low-cost heaters with enamel coating. And sometimes it turns out to be significantly less, because For production, very thin steel is used, and the welding seams are performed on budget technology.

Even if the tank is made of stainless steel, a magnesium cathode must be installed inside it to prevent the oxidation of seams and heating elements. The magnesium cathode during operation dissolves and should be replaced periodically. This should be performed 1 time in 1-1.5 years together with the cleaning of the tank from precipitation and scale. In practice, this is rarely engaged in this, and most consumers prefer to change the water heater once in 3-4 years.

Electrical components

The scheme of using a cumulative water heater.

The quality of thermal sensors and control equipment has great importance for the reliability of the water heater. In our conditions, when there are frequent voltage drops, electronic control devices are less reliable. If the apartment does not set the voltage stabilizer, it is worth using water heaters with mechanical control.

Repair of the failed automation is associated with significant difficulties, because Such spare parts in a large deficit and are expensive. On the contrary, if the mechanical regulator requires a replacement, find a spare part for replacement will not be difficult, and this will not turn into a significant amount.

Connection diagram of the accumulative water heater to the water supply.

The designs of the Tan with closed and open heating elements are distinguished. If there are open-end lads, they have the most close contact with water and the maximum contact area. As a result, heating is faster. But at the same time, the heating elements are actively overlapping and corrosive.

Article on the topic: Wall pastry: 5 tips, where to start glue wallpaper

In structures with closed, the heating elements are enclosed in the flask and do not have direct contact with water. The flask is made by the same technology as the walls of the tank. And just like them, has an enamel coating or a stainless steel case. These tans are more durable and do not require frequent cleaning.

Tips for choosing

Electric accumulative water heater.

Cumulative water heaters produce many manufacturers. And it is impossible to say unequivocally, which of them are the most reliable. You can only roughly designate the price groups in which various options for heaters are offered. What heaters occupy the upper price group, which average, and which are lower.

Manufacturers such as Stiebel Eltron, OSO belong to the class of elite. Typical representatives of strong middle peasants are European AEG, Gorenje, Electrolux, Fagor, Ariston. In the lower segment dominates domestic THERMEX, and various Chinese brands or brands are widely represented, which position themselves as local or European, but at the same time still produce an assembly from Chinese kits. The division is quite conditionally, and different manufacturers can have a different level model.

When choosing a water heater, you can advise not to chase at dumping prices, but choosing, above all, the optimal value for money. Also should not be purchased too expensive models. Often, for large periods of warranty on the tank and the electrician, there are installation work and annual service of certified centers, which in the aggregate can tighten another tank.

Therefore, the most profitable and comfortable option is to purchase a boiler of European average-level boiler with enameled tank and closed by Tan. In this case, you can count on 5-6 years of trouble-free operation, then the heater will have to be replaced. It is worth considering that the service life of the heater largely depends on the quality of your water, water pressure at the inlet and voltage stability in the power grid.

To extend the service life of the accumulative heater, you should not warm the water to temperatures above 65 ° C. At higher temperatures, the processes of corrosion and formation of scale are strongly intensified.