The implementation of the same tasks can be carried out with a variety of fittings, characterized by different principles of the shutter design. Thus, according to the principle of the shutter, the following main types of pipe fittings are distinguished: valves, valves, cranes, flaps, hose valves, membrane valves, level control, flow and pressure regulators.

The wedge gate is designed only to lock the flow of the working substance, it is impossible to adjust the pressure.

The valves are an integral component of the plumbing system. There are different types of valves, each of which has its own characteristics, advantages and weaknesses.

Functional purpose

Depending on the type of product, it can be used to perform various functions:- as a flow regulator of the working environment;

- as pipeline shut-off valves;

- as pipeline shut-off-regulating reinforcement.

The main purpose of the valves is their use as a shut-off fittings - devices needed to overlap the flow of the working medium with a certain degree of tightness.

Similar to their use allows the discrete (two-position) regulation of the flow rate of the working medium.

In some cases, short-term use of valves for performing the functions of shut-off-regulating reinforcement are allowed.

Structural features of the valves

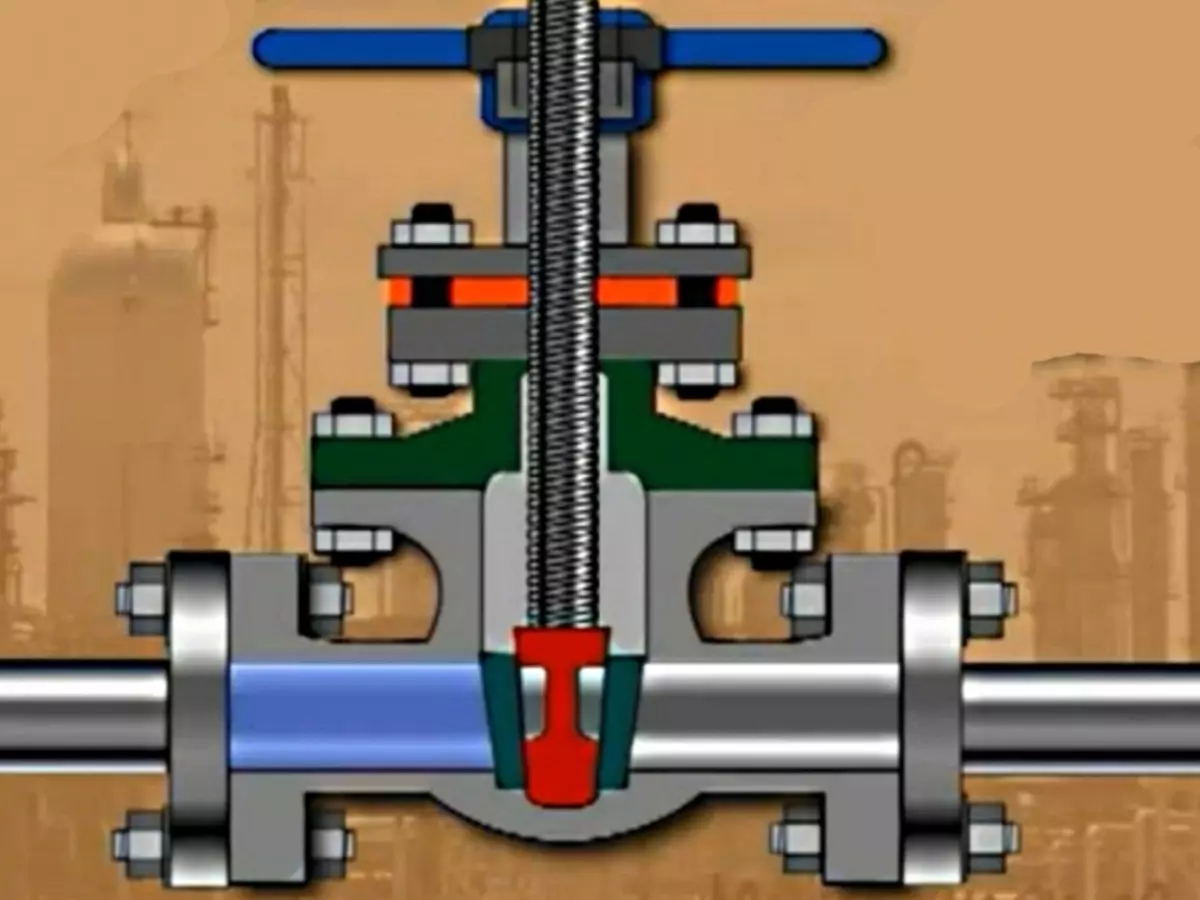

Scheme of basic valve elements.

The valve of each type is different from products of other types for a number of criteria. Depending on the design of the design shutter, the design is divided into parallel and wedge.

The difference between the wedge modifications is that sealing rings are located at some angle, forming a wedge, and in parallel valves such rings are located in parallel with respect to each other.

Wing models are made with solid (elastic or rigid) wedge or a two-disc composite wedge formed by 2 at some angles to each other with discs.

A parallel catch can have a shutter in the form of 1 sheet or disk, or in the form of 2 disks with a spacer spring located between them or the spacer wedge.

Article on the topic: How to make a slope of the input door from MDF

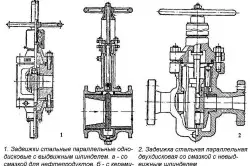

Parallel valves differ from the cast iron. They are used as regulating and shut-off for steam, gases and water. The connection of reinforcement with the pipeline is performed using flanges and bolts. Parallel sloves with retractable spindle are shut-off reinforcement and at the same time can be used as a shutter for regulating the volume of water supplied. They are installed on pipelines, the diameter of which is at least 50 mm.

Shut-off valves can be with a non-adjustable (rotating) or retractable spindle. In the first case, when opening and closing the reinforcement, the spindle makes only a rotational movement. The chassis thread is in contact with the working medium. In the second case, when opening and closing the reinforcement, the spindle makes a translational movement. Chassis carving and nut are located outside the catch cavity.

Control of the locking reinforcement is carried out using an electrical or manual drive. On the armature of large diameters with manual control, a gearbox with cylindrical, conical or worm gears is used to reduce the required effort on handwheeling handwheel.

As a rule, such a shut-off reinforcement is made of full-way, that is, the diameter of the passage of the valves is almost the same with the diameter of the pipeline. In some cases, to reduce the dimensions and mass, reducing the moments and efforts required to manage the locking reinforcement, are used "commercial" valves.

Constructive modifications and basic types of valves

Scheme of drives of valves.

Valves are different types. So, by the type of shutter distinguish the following locking reinforcement:

- with a wedge stop element (wedge);

- with a parallel locking element (girlfriend);

- With elastic deformation of the valve channel under the working environment (hose).

In turn, wedge modifications can be composite wedge, with an elastic wedge and solid wedge.

Sewer valves are a type of shut-off valve, in which the sealing surfaces of the elements of the shutter are located in parallel to each other. Such fittings also has a number of modifications. Thus, one-piece gate models are equipped with 1 disk, which is pressed by the sealing surface to the surface of the housing saddle. In the center of the disk there is a hinge, with which an effort from rods on the disk is transmitted. Proofing can be carried out with the help of wedge triggers installed in the housing.

Article on the topic: how to correctly drag the chair with your own hands

The two-discovery gate products can be both with a wedge and spring springs.

By the method of moving the severity, the shut-off valves may be a turning type and a reciprocating type. In the Sewberry fittings, the seal by Schibur is carried out using spring-loaded moving saddles. There are modifications of rotary type, which are equipped with 2 fixed discs with holes, between which the movable disk is placed. During the rotation of this disk, the working medium is overlap.

The use of elastic elements guarantees providing the necessary adjacent to the contacting surfaces of the discs.

Depending on the type of formation of the body of the product can be:

- licenses;

- welded;

- wrought or stamped;

- Combined.

Scheme of types of valves.

When choosing a method of manufacturing the body of the product, the following factors are taken into account:

- Production program and technological possibilities for the production of products;

- the resistance of the housing of the shut-off reinforcement to the working environment;

- limitations depending on the terms of use of the product (temperature, pressure, corrosion resistance, etc.);

- Qualitative characteristics of the material used for the manufacture of the housing.

In the manufacture of metal shut-off structures, the main type of formation of the body of the product is casting. But with high strength requirements, stamping, forging or a combined method of manufacturing a case are more preferred.

There are other classifications of shut-off products. So, by type of compaction of movable parts, they are divided into:

- self-adventure;

- Silphon;

- Sloves.

Slip valves are the tightness of the moving parts (rod, spindle) in relation to the external environment provided with the help of a gland seal. In the bellows modifications, the tightness of the movable parts is provided with a bellows - an elastic corrugated shell, which preserves strength and density with multi-cycle deformations.

By the nature of the transfer of management efforts to the gate valve are:

- with a transit type;

- with rotational type drive.

By control type:

- from the work environment;

- from hydraulic;

- from pneumatic acting;

- from the electric drive;

- manual through gear;

- Manual from flywheel.

Article on the topic: Vegetable store with your own hands

Features of the shutter design

To understand what the differences between the gate from the valve, it is necessary to figure it out in its destination and design features.

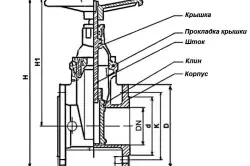

Scheme of a wedge valve: 1 - spindle; 2 - body; 3 - Pour mushroom; 4 - saddle; 5 - Sealing disk (plate).

The main purpose of the shutter is closing, opening or manual adjustment of the streams of technical, sea or drinking water, steam, air and other non-aggressive liquids.

There are several types of shutters. Thus, the rotary disc shutter is a type of pipe fittings in the form of an annular housing with a rotary locking disc installed in it. This disk rotates inside the rubber cuff, providing tightness. It is necessary to take into account the fact that the design of the shutter is incomplete.

The casing of the shutter is made of cast iron and has both internal and outer epoxy coating. The working medium is not in contact with the shutter body. The saddle seal is made of a material that provides the work of the product at a given temperature mode.

The cuff provides tightness of the connection when tightening the design between the water supply flanges. To install the shutter there is no need to use additional gaskets, as in the case of the rest of the interflabian joining designs.

The disk is made of cast iron or stainless steel. The body of the product is clamped between pipeline connecting flanges. The rotary disk is given a movement with a knob with a retainer. The lock allows you to install a turning disk in intermediate positions (from full closing to a complete opening) in a step of 10 degrees.