General characteristics of different types of shut-off valves

The shut-off valve is used in the device of gas pipeline and sewer systems. It can be seen on general purpose pipelines, industrial type, industrial pipelines with special working conditions, plumbing pipelines and many others. They are intended to overlap any water or gas streams.

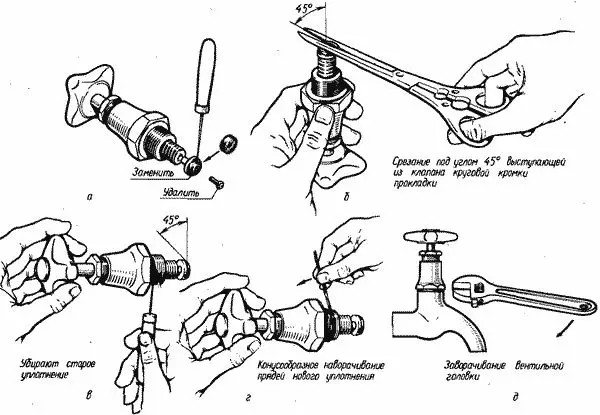

Repair the mixer with your own hands.

For these purposes, the valve, crane, valve, valve, and other locking mechanisms are served. Household plumbing does not work out without such mechanisms, but few understand what the valve crane is different. Without this, it is simply impossible to connect household appliances, eliminate leak, overlap the gas or change the mixer. Plumbing surrounds us completely and near, and shut-off fittings - an integral part of it.

In fact, it has significant differences in both constructive and operational, although any constructive solution of this type of fittings always works in two positions: closed and openly.

But, based on their functional characteristics and applications, one or another type of device is selected. For the correct choice, you should know what the principle of their work may differ, and what function each of them performs.

Principles of working crane, valve and valves

Crane device.

Constructive solutions of shut-off valves are cranes, valves and valves. What do they differ among themselves?

The valves are the most common and the most demanded locking devices. Their design implies the location of the locking element in the position closed and open. The flow of the working medium overlaps due to the fact that the locking element moves perpendicular to its axis. The valves can be applied solely as locking reinforcement. They are parallel, wedge and gathering.

Article on the topic: Facing the base of porcelain and clinker tiles: features and finishing technology

The valve or valve is able to overlap the flow of the working medium due to the fact that the device moves parallel to the axis of its movement. It, in contrast to the valves, can be applied not only as a overlapping device, but also as regulating due to the fact that its design will allow you not to completely overlap the flow of the medium, but partly.

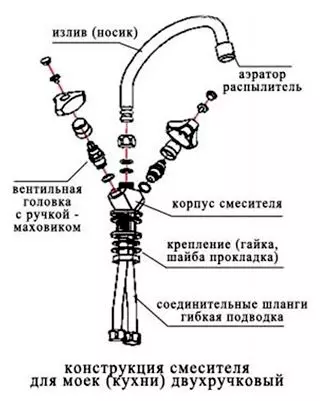

The design of the two-leaf mixer.

A substantial disadvantage can be attributed to the inability of the valve to respond to a changing speed and pressure in the system. Therefore, the sphere of its use is pipelines with a relatively constant stream and pressure of the working medium. In addition to regulating and shut-off devices, there are overrun, mixing, as well as distribution designs of these mechanisms.

Crane is another type of shut-off reinforcement. It can be applied both overlapping and regulating device. It functions so: the shut-off element, rotating around its axis, moves towards the perpendicular movement of the flow of the medium. The shut-off element has a disk form. Due to its rotation around its own axis, there is a liquid overlapping on a perpendicular direction.

Modern plumbing offers a variety of designs of shut-off reinforcement, which have their own features. Of course, this entails the presence of distinctive advantages and disadvantages that are manifested in various conditions. Therefore, in order to correctly select the locking valves, it is necessary to take into account the features of the design of the pipeline, as well as the terms of use and requirements for a specific device. For this you need to understand what is different, for example, a crane from the valve, because the difference between them is not so obvious.

Comparative characteristics of the crane and valve

Crane device with valve

The main difference between the crane and the valve is the adjustment of the head of the working medium. The valve can produce such adjustment, but the crane is not. Moreover, given the rules for the operation of the cranes, the pressure is categorically prohibited with their help. The functions of the crane are only two: open and clear the stream of medium. But the valve can easily adjust the pressure of the fluid or gas.

Article on the topic: What are the electrical schemes

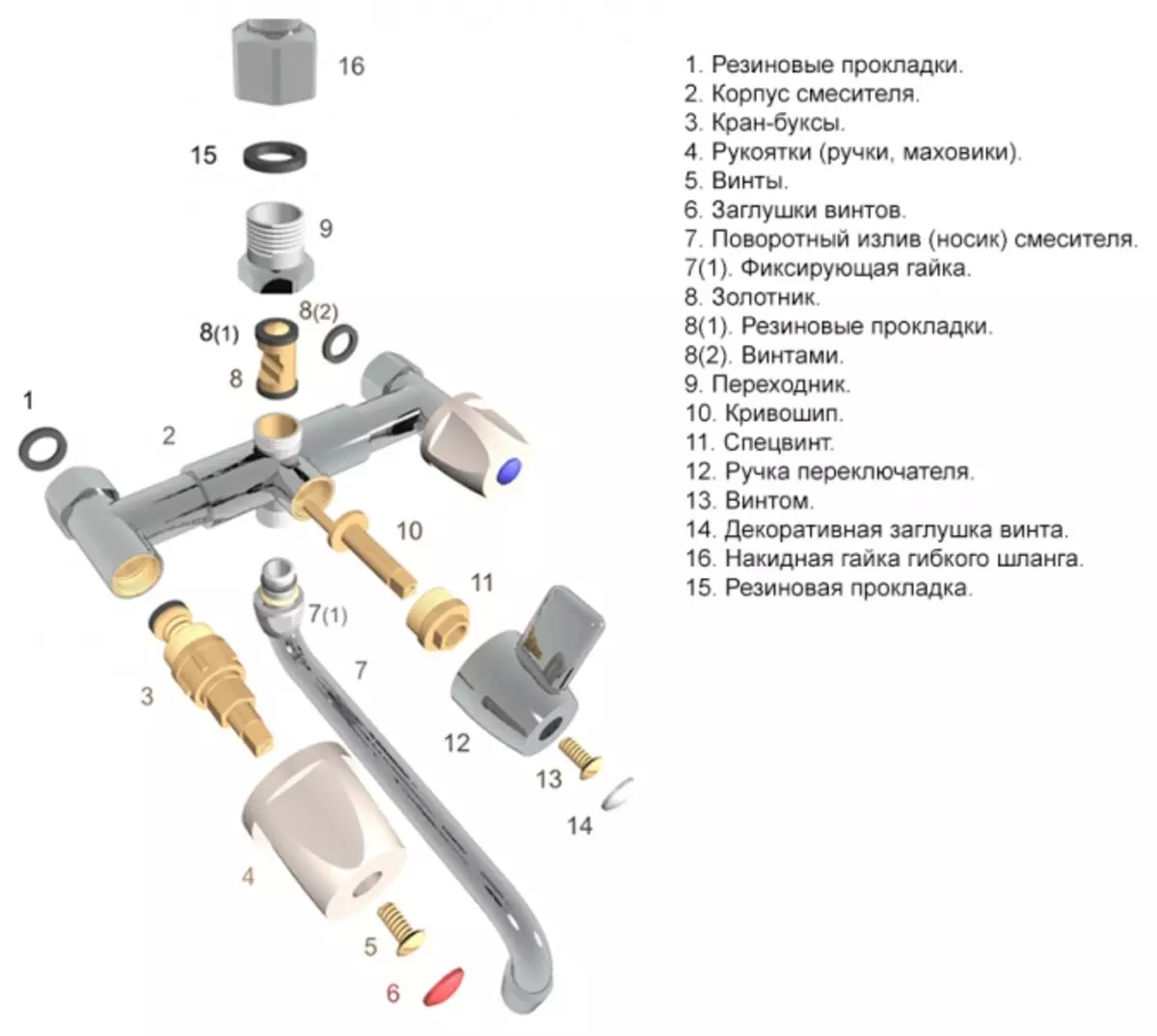

Such a difference is due to the design. The shut-off element in this device moves in the direction of the stream and in the end it sits on the saddle. In the cranes, he rotates around his axis. In addition, there are ball valves. In their designs, the shut-off element performs the ball rotating perpendicular to the flow, as a result of which the diameter of the pipe changes. But the valve is equipped with ground-buxy. This constructive solution implies that by moving the rod of the ground-trays, produce lifting or lowering the valve, which is attached to the stock. Thus, the opening or closing of the hole is occurring, which is in the saddle.

Visually to distinguish the valve from the crane. If the shock fittings have a simple handle, and the end of this handle is attached to the rod, then this is a crane. If on the place of the handle on the stock is lamb - this is the valve.

Valve comparison and valve

The device of the valve mixer.

What is the difference between the valve from the valve? The difference between them lies in the design of these two types of shut-off reinforcement. The valve has a more complex design. In it, the flow overlaps due to the damper or cone, which perpendicularly drops until the stop is stopped, that is, to the complete overlap of the fluid or gas movement. The valve is somewhat simpler. The flow overlaps the valve, which is pressed to the saddle in parallel. Thus, the flow twice bends under 90 °. It increases resistance.

If the valve is designed and done correctly, the passing holes should not be narrowed, if you compare them with input and output. But the valves can not boast. In many pipelines, they put all-wheel drives of their options, which in their diameter correspond to the diameter of the pipeline.

Although there are other options for this device, more narrowed than the diameter of the pipeline. They are installed with a certain goal. Such valves due to the smaller diameter have a smaller torque. This reduces the wear of the seals in the pipe.

Article on the topic: How to store dry apples at home

If the pipeline has a large diameter, over 300 mm, or if the pipeline works under greater pressure, then in such pipelines it is more rational to put valves, as they work more efficiently.

The valve, having a simpler design, has in the end and low cost. In addition, it is easier to rotate under high pressure. But this high pressure creates a residual load on the design, as in the design of the valve there is bends, and high pressure seeks to press the valve from the saddle. There are no bends in the design of the valve, such a stream resistance is reduced. Pressure exists only from the movement of the flow, and it helps the flap to more tightly lay down to the saddle. What provides a valve greater reliability compared to the valve.

The valves cannot act as regulatory elements, and can only completely overlap the flow or completely open it. But the valves can play the role of adjusting devices.