The main difference between the valve from the valve, the analysis of the design features of the design allows you to make the right selection of the reinforcement device when installing the pipeline.

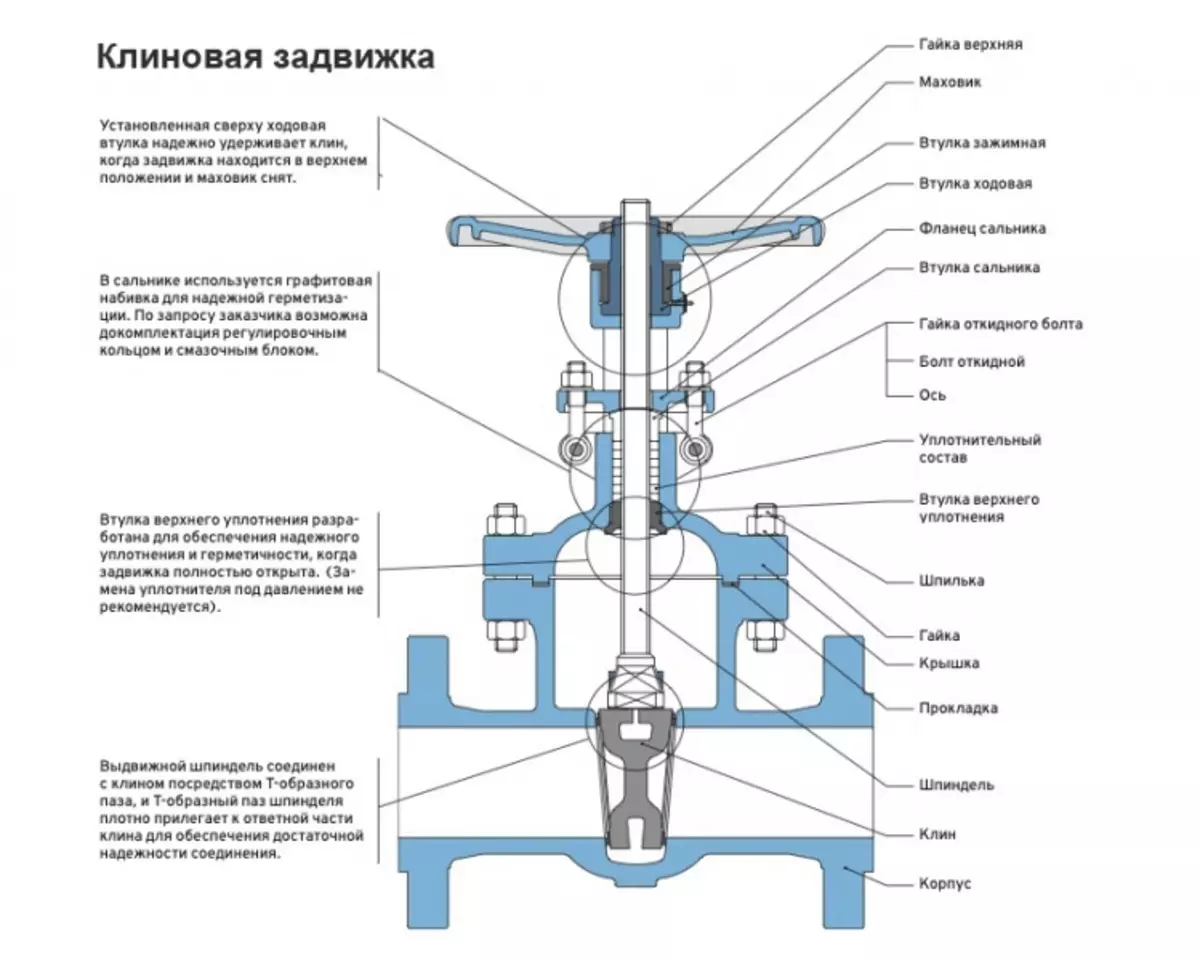

Scheme of a wedge valve.

Device valves

The valve is a reinforcement device that has a shutter in the form of a disc, sheet or wedge moving along the enclosure sealing rings perpendicular to the medium stream axis.Depending on the design of the valve, there may be passage and narrowed having holes of the sealing rings less than the diameter of the pipeline.

Depending on the shutter geometry, the valves are separated into parallel and wedge. Wedge valves are equipped with a wedge shutter with sealing surfaces that are located at an angle to each other. The shutter wedge can be solid elastic, solid rigid or constituent two-disc.

Parallel valves are equipped with shutters whose sealing surfaces are parallel to each other. This design can be one-piece (girlfriend) or two-disc.

The valves can be equipped with a sliding spindle (stock) and non-retractable (rotating spindle). They differ in the design of the screw pair, which moves the shutter. Valves with rotating spindle have a smaller construction size.

Advantages and disadvantages of valves

Valve device diagram: 1 - valve body, 2 - nut, 3 - washer, 4 - gasket, 5 - valve, 6 - seal, 7 - stock, 8 - Specvetler, 9, 16 - gland, 10, 15 - Selnik bush, 11 - Flywheel, 12 - washer, 13 - Screw, 14 - Caid washer.

The main advantage of the valves is that there is no overcoming of the pressure of the medium during the process of moving the working body, which in turn is an effort required to move the shutter. A consistency of the flow of the transported medium and the small resistance coefficient in the open state is considerable significance.

Due to the symmetrical design, the use of valves can be used at different directions of movement of the transported medium, while not excess assemblies and disassembly of flange connections, when it is necessary to change the direction of movement of the internal environment.

The main disadvantage of the structure is that in the process of moving the working body of the valves, strong friction occurs. The valves have a large building height due to the need to extend the rod.

Article on the topic: Living room 9 sq m: How to make an interior design design?

When the shutter is located in an intermediate position, the seaside cross-section is partially overlapping, the flow actively flows into the lower areas of sealing ring surfaces, exposing them to abrasive wear with solid inclusions of the working medium. Therefore, after operation in partial closing mode, the valve is not provided with sufficient tightness when they are closed. This disadvantage is inherent in various types of reinforcement and limits the use of valve as an adjusting element. In addition, the regulatory characteristics of the valves are unsatisfactory.

Application and operation of valves

The valves are used on pipelines with a diameter of more than 50 mm, where smooth overlap of the cross section is necessary to prevent hydraulic impact.They are used in air conditioning and air ventilation systems (as well as in the furnace heating), an analogue of the valve design is a ventilation sewer, which is a metal sheet of a rectangular shape, which moves in the guides perpendicular to the axis of the air duct.

Do not do without valves and in the device of plumbing and sewer systems, a gas pipeline, as well as other industrial engineering systems. Many mistakenly believe that the valves are a variety of valves, but these are different devices that have structural differences that determine the features of operation.

Device and valves

Scheme of the Sewberry Gate Device: 1-Sewber, 2-plate guide, 3-seat, 4-case, 5-ring, 6-rod, 7-package seals, 8-handwheel, 9-pointer, 10-housing Bearings, 11- Cover, 12-oil, 13 ring.

The valve is a valve, the shutter of which moves with a threaded pair. Designs are made in the threaded (coupling) version and for connecting to the flanges of pipes.

Depending on the mutual arrangement of the output and input connections, angular and passing valves are separated. The categories of passages include constructions that the axes of the output and input connecting pipes are parallel or coincided. The angular valve, in turn, is equipped with mutually perpendicular axes.

Depending on the purpose, they are divided into shut-off, safety, regulating, cut-off, bypass, respiratory, reverse.

The valve can be positive and two weeks. Single-week valves, in turn, in the form of the shutter are divided into needle and dish. A valve having a manual control in which the shutter moves with a threaded pair, is often called the valve. Distinguish regulating and stop valves. The purpose of the shut-off valves is the complete overlap of the medium flow, for this they are equipped with a shut-off body.

Article on the topic: Bathroom cornice: Features of M-shaped structures

Membrane valves - armature designs in which the overlap of the flow of the medium is performed using the elastic deformable membrane (plastic, rubber). These systems are made of cast iron with an internal coating of corrosion-resistant materials (rubber, plastics, enamel).

The hose valve is the design of the reinforcement, in which the overlap of the medium flow is implemented due to the persuasion of the rubber hose located inside the valve. Valves are used both with one-sided and bilateral hose.

Scheme steel valves with retractable spindle.

The respiratory valve is designed for the release of accumulated air or vapor and prevent vacuum formation in tanks in the process of "big" and "small" breathing. The concept of "large" breathing occurs at the cost and flow of fluid, "small" is caused by temperature fluctuations.

Thanks to the check valves, it is possible to prevent the formation of the reverse stream of the medium. In the check valves, the locking body opens with a direct stream of medium and is closed by reverse flow. The lifting reverse design of the valve has a shutter that makes a reciprocating movement. Constructions, equipped with a mesh, are installed at the beginning of the suction pipeline. The rotary check valve is equipped with a shutter rotating around the horizontal axis, which is located above the center of the valve seat.

Advantages and flaws of the valve

The main advantage of the valve is the absence of friction of sealing surfaces, when they are closed, since the shutter moves perpendicularly, which in turn reduces the risk of damage. The valve has a lesser height in comparison with the valve due to the fact that the stroke of the spindle is small and is no more than ¼ diameter of the pipeline. However, they have a greater construction length, as it is necessary to deploy the flow inside the case.

At the valve, the shutter moves perpendicularly, at the time of closing the system, the sealing surfaces of the friction are not tested, and this prevents the occurrence of scaling.

The lack of valves is a large hydraulic resistance. It occurs as a result of changes in the direction of flow of the working medium. Such a change is twice occurs inside the device housing.

The valve is characterized in that it has limitations during operation and can only be used at a certain direction of movement of the working medium. The design is predetermined that the flow should leak under the plate and put pressure on it from the saddle in the closed position. Opening the valve provokes a seer of a plate from the saddle. If the valve is focused in the opposite direction, then in the closed position, the plate will be attached to the saddle, which will create significant difficulties when opening. As a result, a breakdown of a plate from the rod and the output of the valve is out.

Article on the topic: How to dock plasterboard in the corners and the construction of a decorative niche

Constructive and functional difference valve and valve

What is the difference between the valve from the valve? The difference is due to the design of their locking bodies. In the valves, the gas flow or fluid overlaps with a valve, which is pressed towards the saddle in horizontal planes of parallel stream, for this, a double bending of the gas flow or liquid at an angle of 90 ° is made, but the resistance increases.

Unlike the valve valve, the valve is equipped with a flat plate-shaped or coneoid shutter, it makes reciprocating movements along the saddle surface.

In the valves, the flow overlaps due to the damper or cone, descended perpendicular to the direction of flow movement.

With the proper design of the valve, there are no narrowing of the conductive holes, in comparison with the input and output. In the case of using valves, a number of options are possible. In most pipelines, all-wheel drive valves are installed, in which the diameter of the conductive hole corresponds to the diameter of the pipeline, however, it is often for the aim of reducing the torque of the torque and narrowed valves are used, which makes it possible to reduce wear of sealing surfaces.

With high pressure or diameter of pipelines, more than 300 mm are more efficient valves. The valve also has a simpler design, the consequence of which is lower cost. In addition, they are easier to rotate with a large pressure, but at high pressure as the desire to press the valve from the saddle, an additional load on the design is created. In the valves resistance is completely absent, as they do not have bends.

Thanks to one-way pressure, a more dense adjacent of the flap to the saddle is ensured, making the valves with more reliable locking devices.

The blocking element of the valves can either completely overlap the flow of gas or liquid, or be fully open, the valves in turn can perform the function of regulating elements.