Sometimes it happens that it is difficult to choose the extension agent of the required length, which is designed for a certain power.

In addition, there is always a risk of stumble upon low-quality products. The most optimal solution will make the extension with your own hands.

Initially, it is necessary to clearly determine how and for which the extension can be used, the instruments with which power will be turned on, and also in advance to label the power supply to the future. Perhaps in the future it will be necessary to include instruments having a greater power, and in this case the earlier supply will help you protect yourself from possible troubles and you will not need to buy a new extension.

There are articles in which it is described in detail because of what the extension can be blocked, which will happen if you submit a powerful load through it, which it is not able to withstand.

How to make an extension with your own hands?

The extension agent includes three main components:

- block sockets;

- electrical plug;

- Cable (most often used PVA brand cable).

The plug and sockets block are usually made for maximum current 16a (3.5kW) or 10a (2,2kW). In accordance with this, if you plan to connect the instruments, the power of which does not exceed 2kW, then the block of sockets and plugs are enough for 10a, and the cross section of the wire should not be less than 1 mm2.

If the power of the connected instruments exceeds 2 kW, then it is necessary to stop its choice on the outlets block and fork on 16a, with the cross section of the wire should not be less than 1.5 mm2.

In this example, the extension will be manufactured in which instruments that have a power of no more than 2 kW will be connected, so the PVS-2x1.0 wire will be used, as well as a socket block and a plug on 10a.

Article on the topic: how to make sketches curtains a pencil yourself

In most parts of the apartments, electrical wiring with two wires is still used, so the manufacture of a two-wire extension agent, which does not have grounding.

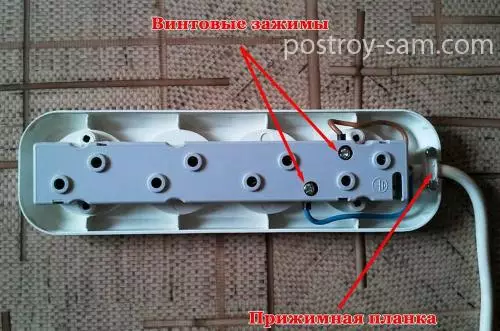

You need to disassemble a block of sockets, twisting four self-pressing. Inside, you will find a contact group and two screw clamps to which the wires will be connected.

You also need to disassemble the plug, reloading one self-tapping screw.

Now you need to cut off the required length of the wire, and then remove the isolation from both ends of the wire to the desired length.

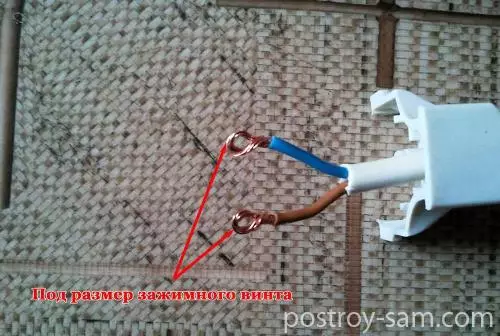

It is very convenient to operate a multi-boiler wire, as it is flexible and soft, but while connecting it to the screw terminals, its wires can be transmitted, which is why the contact can be disturbed, and heating and sparking may appear. Therefore, it is necessary to the wire or disappear, or use the crimping tips of the NSHA.

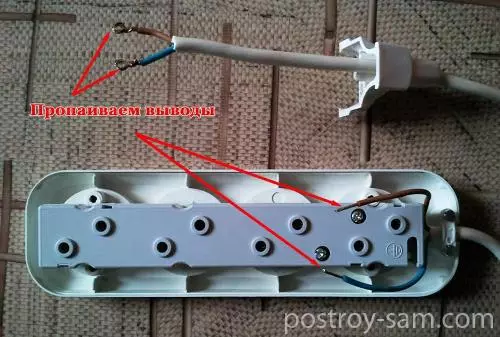

You can put the wires of the sockets block with tips if you have press clamps.

Now you need to start the tip in the screw clamp and fix it is securely with a screw.

It is necessary to wear the top cover of the fork on the wire, clean the wires and tighten them with a ring under the screw, which will clamp them.

If you do not have a press tick, then we need stripped wires to do with solder, both from the side of the sockets and the fork side.

In the wire outlets block, you need to start the clip and thoroughly tighten with screws. The wire itself must be attached to the sockets block housing using a pressure plank and two screws so that during the operation of the wires it is not pulled out of the screw clamps. Similarly, you need to fix the wires on the fork using the screws with the washers. After that, you can collect a block of sockets and fork.

Now it remains only to check the multimeter the correct assembly. To do this, you need to translate the multimeter switch to the buzzer mode or resistance measurement. One dipstick must be placed in one socket of the sockets block, and the second probe touch to some contact fork. If the sample is connected to one wire, then the buzzer or the multimeter will show the zero resistance, and if to different wires, then the buzzer should not squeak, and the multimeter will show a break. Then you need to rearrange the probe in the sockets block and continue checking. When everything is checked, the extension can be used.

Article on the topic: Features of the installation of electrocamines in the interior