Ceresit products use in great demand in our country, and therefore is available in all construction and business stores. Ceresit is a manufacturer with more than a century history, from the end of the last century, which is part of the Henkel corporation. The company received world fame thanks to the highest quality of its products and high market coverage. Among other things, Ceresit produces construction mixtures for molding interpatine seams.

To date, six types of races designed for different facing materials and conditions of use are developed. To understand all the variety of choice, learn about the methods of working with the grouts Ceresit, as well as to get an objective opinion about the company's products, this article will help you.

Benefits

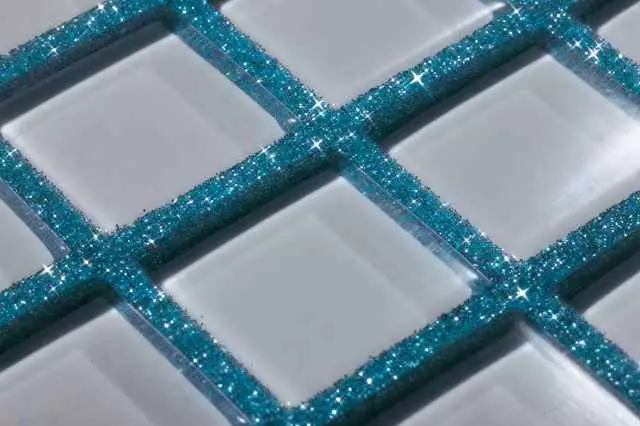

- The ability to select the desired type of grouting from several offered by the manufacturer. There are grouts for ceramic tiles, mosaic, artificial stone and other facing materials.

- A variety of grouts can be selected not only on the basis of the facing material, but also with the conditions of operation. For example, Ceresit releases grouts for premises with an increased degree of humidity, external walls, pools, industrial premises, etc.

- Another important parameter to which you can navigate when choosing a Ceresit grout is a seam width. The manufacturer releases grouts for seams width from> 5 to 30 mm.

- Also in the assortment of the manufacturer there are grouts designed directly for use at very high or very low temperatures.

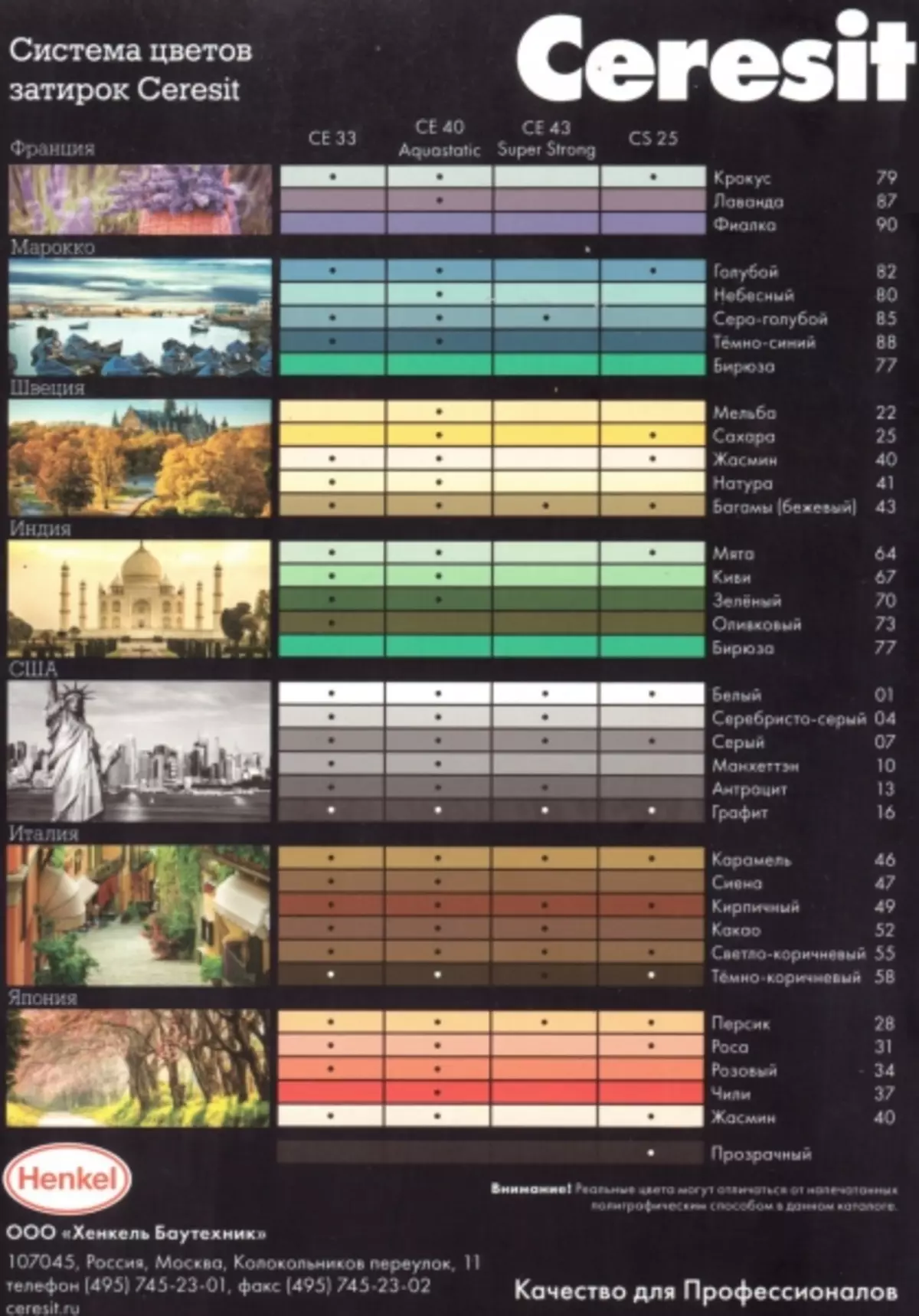

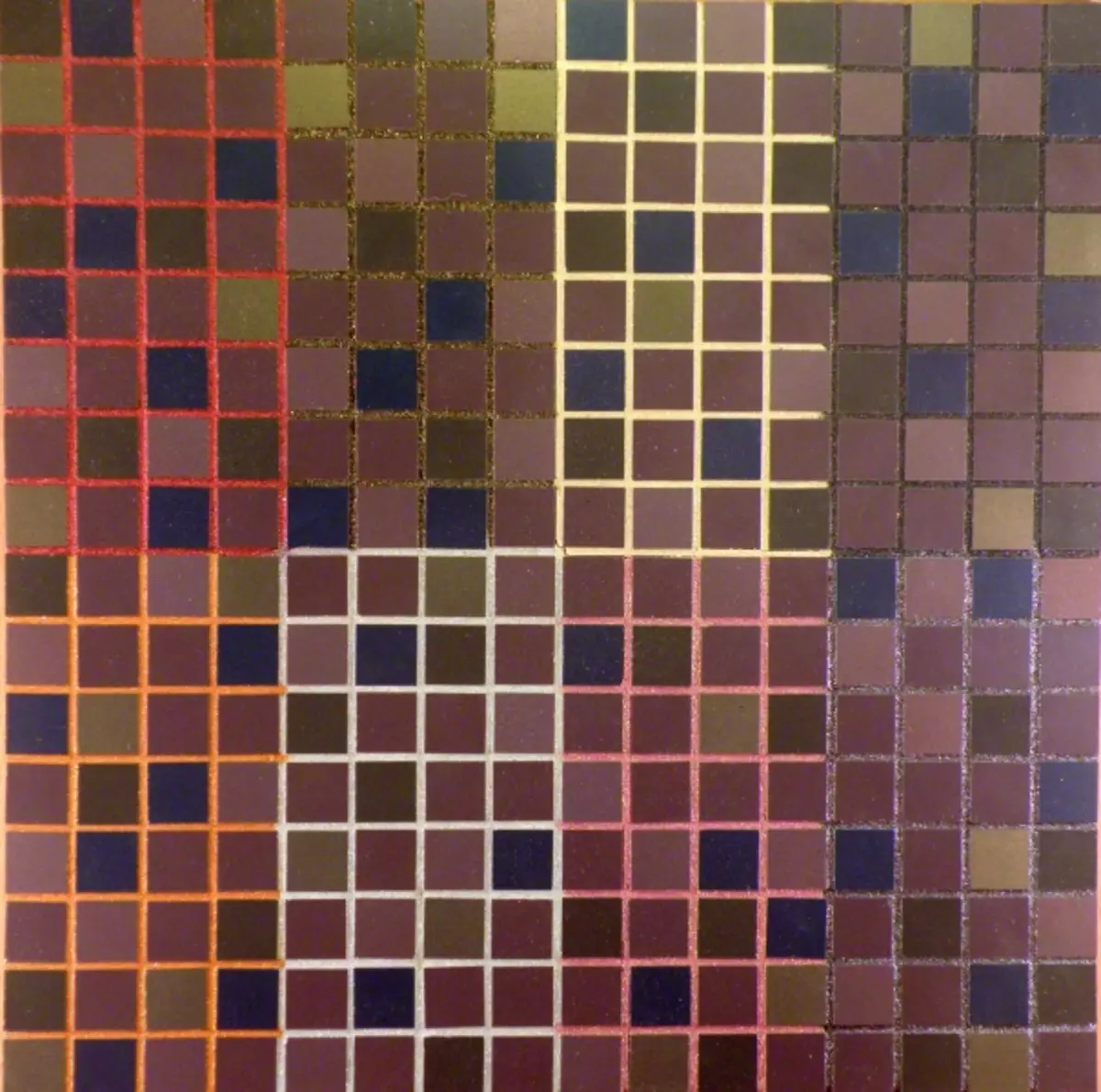

- Another undoubted advantage of the Ceresit Stales is a rich color palette. You can choose the desired color for any type of tile: a monophonic, multicolor or decorated pattern.

- Masters finishing marked the good wear resistance of the Ceresit rap.

disadvantages

- Many of those who enjoyed Ceresit marked one feature: after drying, the color of the material varies and sometimes it differs significantly from the one that is specified on the package. Therefore, it is better to purchase a grout in the store where you can test the test sample.

- The manufacturer packs some types of Ceresit grip in paper bags. If all the storage and transportation conditions are met, the packaging does not matter, but sellers do not always comply with these conditions. That is why buyers often complain that the Ceresit packaging misses moisture, which adversely affects the quality of the product.

Article on the topic: Features of IKEA countertops

Views

- Ceresit CE 33 Super. It is intended for sealing interchanger seams less than 0.5 cm wide. You can use for cladding of external walls. It is best suited for finishing a toilet and the kitchen area is distinguished by resistance to low temperatures. It has antibacterial and anti-grapple properties.

- Ceresit CE 35 Super. It is intended for sealing interporter seams, a thickness of 0.4 mm to 1.5 cm. It has water-repellent properties, it is well tolerating the effects of sun rays and precipitation. Suitable for use in pools. This type of grout Ceresit should be chosen if you work with lining from decorative stone, marble and other similar materials.

- Ceresit CE 43 Super Strong. Grouting of increased strength, intended for sealing intercine seams with a thickness of 0.4 to 2 cm. It is suitable for use in any conditions, as it has waterproof and hydrophobic properties, resistant to solar rays, precipitation and temperature drops. This grout can be used for most facing materials, other than marble and glaze tiles.

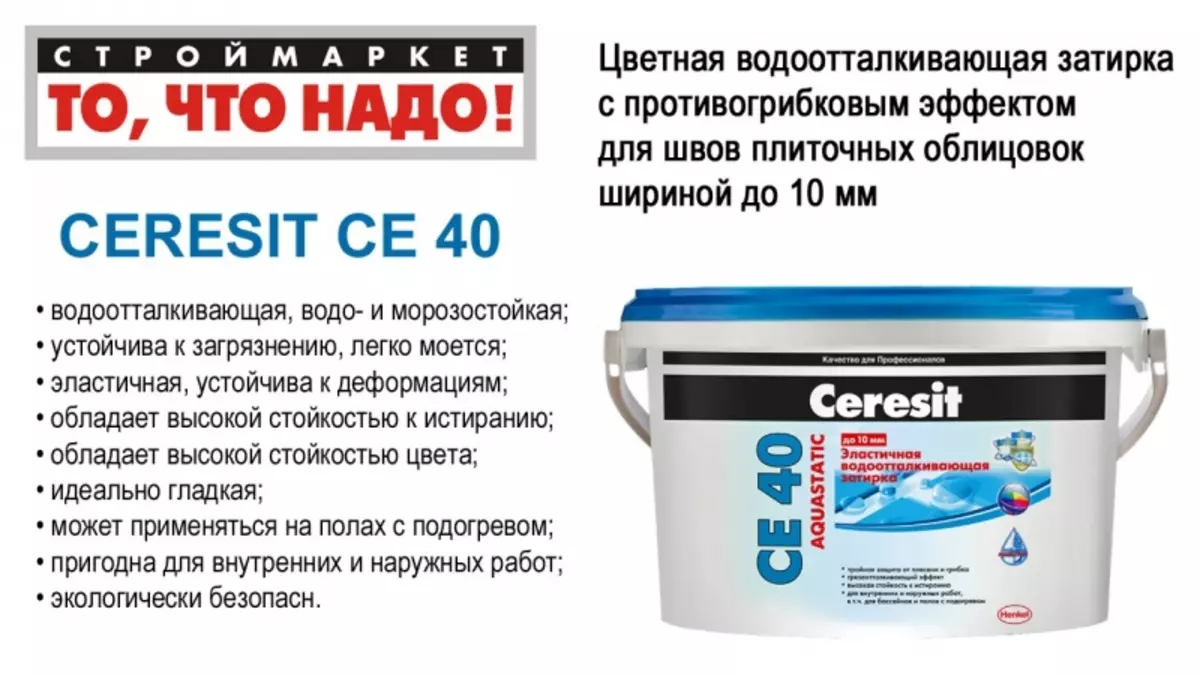

- Ceresit CE 40 Aquastatic. It is intended for sealing interpute seams with a thickness of up to 1 cm. It is well tolerates the effects of high and low temperatures, as well as the temperature drop, is therefore recommended for use in rooms with heated floors or on the street. It has mud and water-repellent properties.

- Ceresit CS 25. Silicone-based grout, intended for sealing interpatine seams with a width of 0.5 to 3 cm. Ideal for use in the bathroom, including for finishing a shower. It has good anti-grapple properties. This grout should not be used for facing the kitchen area.

- Ceresit CE 79 ULTRAPOX. Epoxy grout intended for sealing seams of any width. Like all two-component grouting mixtures, is characterized by high resistance to abrasion. It can be used for cladding external and inland walls. It tolerates the impact of chemicals contained in cleaning products.

Take a sample tile for easier selection of grouting.

Article on the topic: Redevelopment of a four-room apartment in a panel house

The time of complete grout drying, as a rule, is about 24 hours.

Consumption

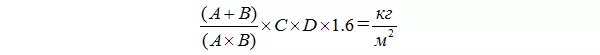

The flow rate of the grout, regardless of the manufacturer, is calculated by a simple formula:

where, a, b, c is the length, width and thickness of the tile, respectively, D is the width of the seam.

Ceresit wipping consumption also depends on the variety of grouting mixture. So, for ceramic tiles of standard sizes, the flow of different types of grouting Ceresit on one square meter will be the following:

Tile size, cm | 5x5 | 10x10 | 20x20 | 50x50 |

View of Zatirki. | ||||

CE 33 (kg) | 0.5. | 0.4. | — | — |

CE 35 (kg) | — | — | 0.4. | 1.2. |

CE 40 (kg) | 0.5. | 0.4. | 0.5. | 0.2 |

CE 43 (kg) | — | — | — | — |

CE 79 (kg) | 1.3 | 1.0 | 1.3 | — |

CS25 (ml) | 25. | 100 | — | — |

Instructions for use

In addition to cement grout for tile, Ceresit also produces epoxy and silicone-based grouts. If the rules for handling ordinary grout are known even to novice masters, then not everyone is familiar with the use of new types of grouts.

Epoxy

Epoxy grout is very important to mix correctly. In the Ceresit epoxy grout package, there are two active ingredients that should be connected by thoroughly observing the proportion. Mix the grout using a mixer at high speed.

It is important to remember that 1.5 hours after mixing, the mixture begins to harden, so the epoxy grout must be prepared in small portions.

Seams should be filled with a conventional rubber spatula. The procedure for work here is the same as with a cement grout, but you should remove excess grouts from the tile on time. Epoxy grout can only be considered only a special sponge moistened in water (while it is necessary to ensure that the water does not fall on the empty seams, as it is permissible to work with epoxy grout). After the work is over, you need to consider from the plastic tile, the flare remaining from the grout. For this purpose, special cleaning products produce. Be sure to purchase one of them, because in another way it is impossible to get rid of epoxy marks.

Silicone

Silicone claw-seelate Ceresit is sold in cartridges, so it can be applied by means of an assembly pistol, which greatly facilitates the task.

- Before starting work, take the edges of the tile by paint tape to protect the coating.

- If the intercutric seams are very deep, it is recommended to pre-insert the polymer harness in them.

- Now you need to prepare the cartridge: cut it on the tip on the thread and secure the tip on it. Then cut the tip in such a way that its diameter corresponds to the width of the seam.

- Severe a tank with a mounted gun.

- Fill the seams, not forgetting it from time to time to smooth them (this can be done with a finger moistened in the soap solution). It is important to have time to correct the seam no later than 15 minutes after applying the grout.

- Remove the remains of fresh grouts can be using alcohol or solvent. And the frozen grout can only be carefully scraped, trying not to damage the tile.

Reviews

Since Ceresit products are actively used not only by the masts and finishers, but also simply people who make repairs in their own apartments, on specialized forums dedicated to construction and repair, discussing products of this manufacturer are constantly underway.

The most frequent problems that occur during the use of the Ceresit vetpers:

- Grout is not mixed with water, but is going to lumps. Most often, this is due to the fact that the master preferred to stir the grout manually. Even with long stirring, you will not succeed in achieving the same result as using a mixer. Ceresit grouts should be mixed only by mechanical way.

- Color grout is wedged with water even a few days after applying. In the manual for color grouts from Ceresit, it is said that the first contact of the interputric seam with water is possible not earlier than 7 days after the decay. Therefore, the remnants of the grouts from the tile should be deleted very carefully, watching not to wet the seam.

- The grout color from different packages may vary for several tones. The shade of the grout mixture depends on many factors. The manufacturer knows about this feature of its production. Therefore, if a large amount of work is scheduled, it is recommended to buy the entire grout from one batch (the batch number is specified on the package).

Article on the topic: Embroidery with a cross scheme: in a hat man and woman, sets in red, with jug and cycling, with umbrella