Water "warm" floor is a low-temperature heating system with a common line, according to which the coolant is supplied to high-temperature radiators. Therefore, an additional element appears - a mixing unit for a warm floor, designed to reduce the temperature of the circulating water. Otherwise, excessive heating of the floor cover will cause discomfort during operation, the screeds will experience critical loads, which will reduce the structure of the structure.

Purpose of the mixing knot for a warm floor

The standard coolant temperature for heating radiators at the outlet of the boiler is 95 - 90˚С. Less frequently apply 85 - 70 degree heating registers. According to the SNiP, Sanpine is comfortable for the operation of the flooring, the temperature of 50 - 35 ° C is considered. Therefore, water from the boiler can not be allowed into the floor outlines directly. The question of its decrease is relevant for water systems of any type. It is possible to do without a mixing assembly, only when using a heat pump. The presence of any high-temperature consumer (shower, bath, wall radiators) will require the installation of the submersion node.

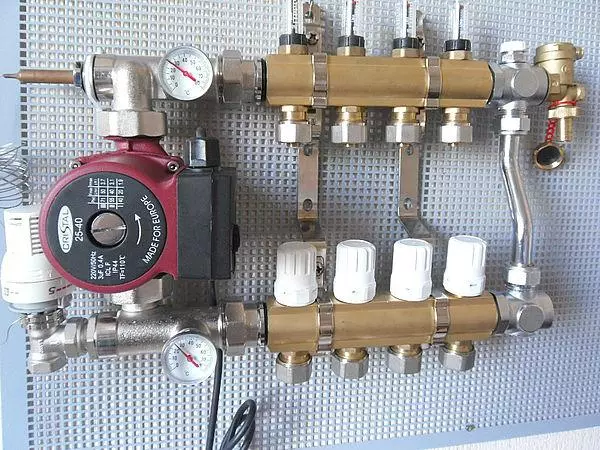

The mixing unit for a warm floor is mounted on the wall either in the niche in the same room where heating contours are laid. There are modifications with two, three chassis valves that are popular with "combs" for a similar shape. Connection nuances make installation inaccessible to the home master, the temperature calculation is required, therefore, ordering services in a specialized company is preferable to increase the operational resource, error exclusion.

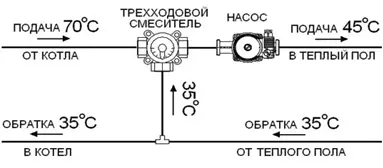

Scheme of work unit

Boiling water from the boiler comes to the room with heating circuits inside the screed, rests on a mixing unit for a warm floor, where the thermostat is measured by the temperature of the coolant. If the return valve opens, the fluid valve opens, the fluid boiling water, which gave thermal energy when passing through the pipes of one of the contours. When the temperature specified in the settings is reached, the main valve opens, water enters the system. There are two main scheme for inclusion of the node into the system, the selection depends on the operational conditions in a particular room.

Article on the topic: How to make a lamp from LEDs with their own hands?

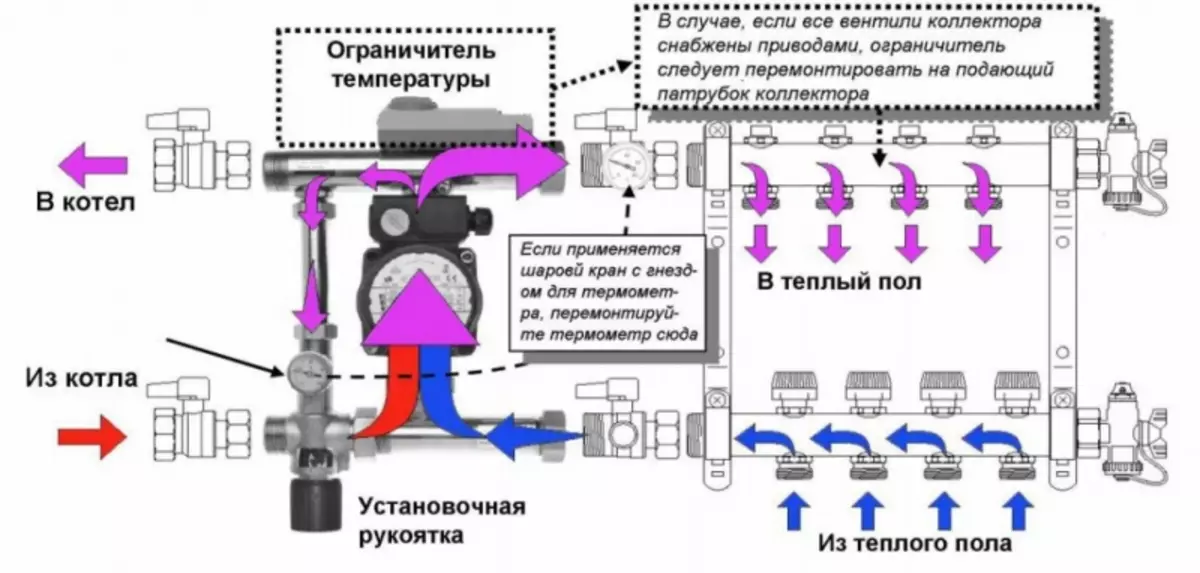

In addition to regulating the temperature, the collector "comb" provides normal circulation of the coolant. The node consists of the following elements:

- Valve - Provides temperature control at the output, periodically mixes cold water from the return

- Pump - needed for circulation with specified parameters to ensure uniform heating of the entire surface of the floor covering

- Bypass - optionally mounted, protects equipment from overload

- Blowers - control the content in the coolant O2

- Valves - cutting, drainage, stabilize the operation of the contours

To increase the artistic value of the interiors, the collector node can be carried into a boiler room, a collector wardrobe in a separate room. The second option is optimal in the presence of a warm floor in several cottage / apartments. The most popular three, two chassis valves in various installation schemes.

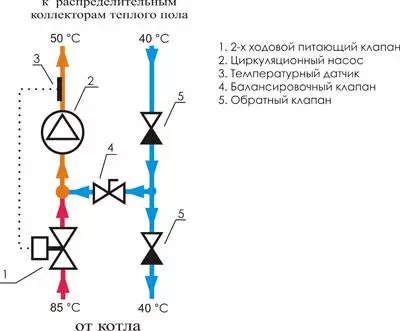

Two-way valve in the mixing unit

The main difference of the collector "comb" with a two-way valve is a continuous feed from the return without cutting reinforcement. The mixing assembly for the warm floor periodically mixes boiling water into it when cooled by the coolant is below the specified level.

The valve is called the feeder, a liquid thermostat sensor that cuts / adding hot water is built into it, which cuts / adding hot water as needed. Due to the stable temperature around the perimeter, the design has a high operational resource:

- sharp jumps smoothed by small valve bandwidth

- Temperature control range is insignificant

- The scheme perfectly proven itself in practice

The only limitation is the excessive magnitude of the contours. When heating more than 200 squares, the drop in the temperature of the return temperature is too significant, the mixing of boiling water becomes not effective.

Three-way valve in the mixing unit

The versatile equipment is considered a mixing unit for a warm floor with a three-way valve.

This device uses another design:

- boiling water is mixed with the return inside the case

- The function of the supply valve is combined with bypass balancing

- The valve with adjustable position is built into the crane

This type of regulating reinforcement is more often equipped with weather-dependent controllers, thermostats, servo drives. It is optimally suitable for multiple contours that are heating more than 200 squares.

Article on the topic: how to paint the bar on your own

The disadvantages of the three-way design are the possibility of inlet of a hot heat carrier, the presence of overpressure that provides sharp jumps. This is unfavorable for water pipes, the construction resource is reduced. Accurate temperature adjustment is complicated by increased bandwidth. A minor turn of the flap leads to a change in the temperature of the floor covering by 5 - 3˚С.

Weather-dependent fittings are mounted for self-regulation of heating contours of outdoor temperature. With strong frosts of heat loss through the supporting structures, double-glazed windows increase, intensive heating is required. Raising boiling water flow, coolant temperature.

Mixing assembly circuit

Factory readiness products that have passed bench crimping, having the necessary documents on hydrotypes produced, are the optimal option for the installation of orange heating systems. The node has a compact type, guarantee of the tightness of threaded, welded joints, ergonomic location of the controls. For ease of installation, the industry releases shields, cabinets for disguise equipment while maintaining access to regulatory reinforcement. An example of the inclusion scheme "Comb" is shown below:

The coolant from the feed pipe, the returns can be mixed in each removal or before the collector. The optimal scheme is calculated by experts, the home master for this is usually lacking professional education, practitioners.

Setting up the styling node

After installing the collector, it is adjusted to the removed servo, the thermal head. To adjust the temperature of the floor surface, you must perform a sequence of actions:

- Installing Max bypass valve - it is translated by 0.6 bar, when this node is triggered when setting the result will be incorrect

- Calculation of the balancing valve - for this, the values of the temperature of the invertation of the feed line are used, at the outlet of the boiler, the coefficient 0.9 (the bandwidth formula K = 0.9 * [(TK - TO / TP - TO) - 1])

- Pump setting - the flow rate of boiling water is calculated, the loss of contour pressure is either the minimum feed is set, as needed speed is added.

- Balancing of branches - regulators fully open, smoothly close to the desired position

Article on the topic: Wall decoration by plastic panels with their own hands

At the last stage, it will remain linked to the consumption of the mixing assembly with other heating devices, adjusting the position of the balancing valve closed at the first stage. Installation of flow meters greatly facilitates the exact setting of all nodes. The valve processing value is set to 10 - 7% below the maximum pump pressure.