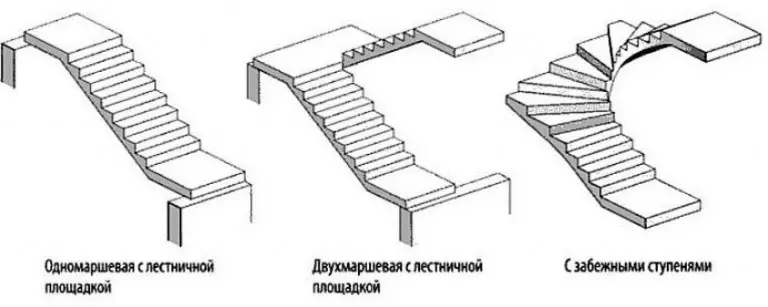

The basement - the room is not presentable, but for ease of use requires the presence of a staircase. She must possess two criteria: be comfortable and reliable. Most often in the basement arrange a single-hour construction. The material is selected different. Make such a staircase in the cellar will not be difficult. You need to start from the project and select the material.

Ready stairs to the basement

The staircase in the basement can be mounted independently, but not always there is time. On this occasion, it is not necessary to be upset, because in almost every construction supermarket you can see the finished structures presented by different manufacturers.

A variety of materials and interesting design solutions will allow the consumer to find the desired options for stairs to the cellar. For those who are busy, there are no time to go to shops, there is another way out - the Internet will come to the rescue. You can find many professional construction sites on which there is a huge selection of stairs.

Wood staircase - economical solutionParticular and folding ladders in the basement and the attic are especially used in demand. The latter can be equipped with a hatch.

The only moment that says not in favor of finished designs is suitable only for standard basement. If there are some nuances, you will have to build a design yourself or with the involvement of masters.

Material selection

The material for the manufacture of the ladder plays an important role. The choice depends on the complexity of the work, financial capabilities, as well as how durable, reliable and durable should be a staircase.

The main options are:

- Wood. It is characterized by simplicity in processing and availability. But, the wooden staircase in the basement requires careful processing and protection against moisture, mold and fungi. The basement microclimate is not quite favorable for wood. Therefore, besides the material itself, you need to spend on protective substances.

- Metal profile. Metal staircase is very reliable and durable design. At the same time the price of its device increases. Requires processing and protection against moisture. It is necessary to remove rust and cover the paint material in several layers.

- Concrete. One of their most durable materials. But it is suitable only for spacious basements. The concrete design itself is cumbersome and takes more space than wooden or metal. Despite the strength of concrete, he also needs protection. To do this, finish steps with paint, tile, rubber coating.

In the event of a selection of wood or metal, you can construct and install the screw type of the stairs. The advantage of this type of product is compact.

Calculation of gabarites

The construction of the staircase in the basement of the house begins with the calculations and drawing up the drawing. The optimal indicators of the size of the staircase are:

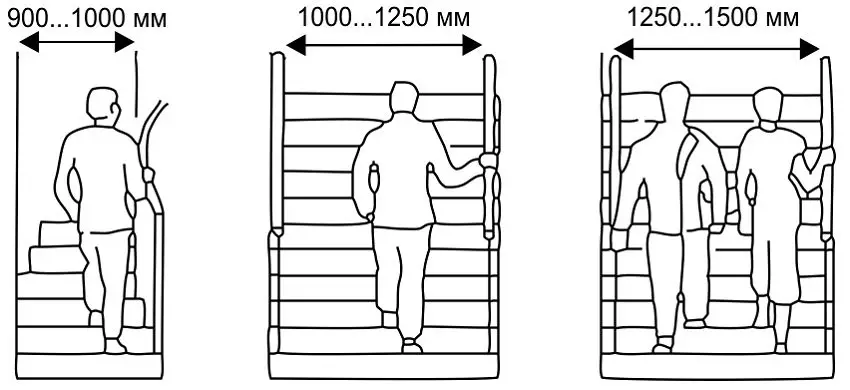

- Marsham width. The parameters 0.9-1 m are suitable for the standard option. If the space of the room allows, you can expand a little march.

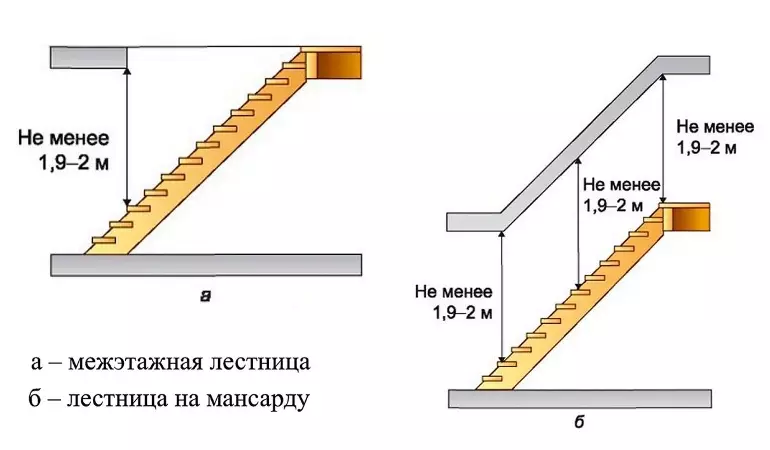

- Lumen. It is height from the position of the step to the overlap of the basement. This parameter is based on operation. The user should not touch the ceiling head. In the maximum narrow place, the clearance should be equal to the average human growth plus 10-20 cm.

Article on the topic: Features forged stairs: species, advantages and manufacturing technology | +55 photos

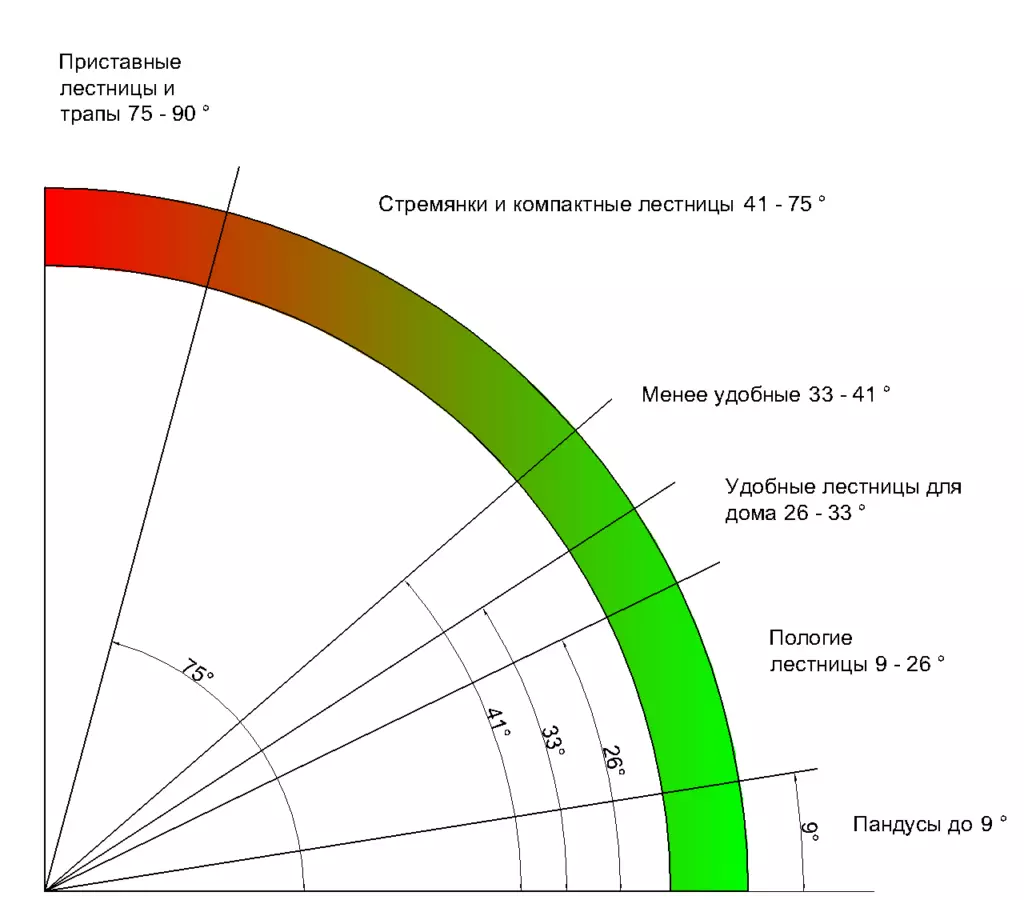

- Steepness. The largest bias at the gear structure 75. If a stationary staircase is satisfied, then the less it will be cool, the easier it will move on it during the descent or lift. But it takes more space. The optimal option is 26-32.

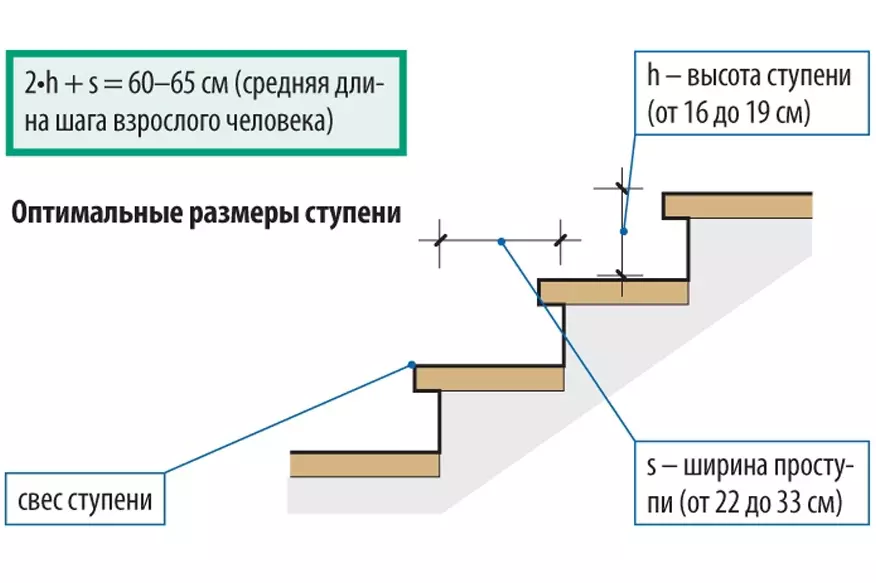

- Stage depth. This value is usually no more than 30 cm. In conventional situations, the depth of the stage is trying to make in accordance with the size of the person's leg. For the basement, this condition is not necessarily, since the addition in parameters increases the length of the entire design and, therefore, it takes more space.

- Stage height. Ranges from 15 to 20 cm. This is the optimal option for a comfortable movement. No need to high raise your legs. It is necessary to ensure that the height of all the steps is the same. In the case where the march length is not divided, then extra centimeters are added either to the first or last stage.

Calculate the number of steps in the following way: the length of the design is divided into an estimated height of steps. For example, with a staircase height of 2.5 m and a stage, 0.15 m is obtained as a result of 16.6 elements. Since the figure is not a whole, then they are applied as follows: 2.5 m are divided into 16 and obtain a height of 0.156 m or 17, then the height of the step will be 0.147 m.

Construction of concrete ladder

The staircase made of concrete for the basement in a rustic home is the perfect option. The benefits are obvious:

- not subject to corrosion;

- not bend;

- Will not creak over time.

The minuses include the fact that it is better to mount it at the stage of building a private house. If such a situation happened that the idea came later, then it is necessary to prepare for this time-consuming process and, possibly, considerable costs.

Before making the stairs to the basement with your own hands, it is necessary to calculate not only its parameters, but also the number of necessary material:

- cement, sand, crushed stone;

- reinforcement for reinforcement;

- Lumber for formwork.

All nuances are thought out at the stage of drawing up drawing, as the design is monolithic and make adjustments will not be possible.

Individual counts are especially important in the event of a screw construction or option with running steps.

Step number 1 - Production of foundation

The preparation of the foundation for the concrete staircase depends on which sex is arranged in the basement. If a concrete slab is a rather impressive thickness, then the base is not necessary to build. Otherwise, at the place of fitting the product to the floor, the site is placed with dimensions a little more march width.

To ensure the foundation, the upper layer of a depth of 0.5 m is removed. Pulling up a crushed stone with a thickness of 20 cm, it is tightly tamped. On top of the layer poured concrete consisting of sand, cement and rubble.

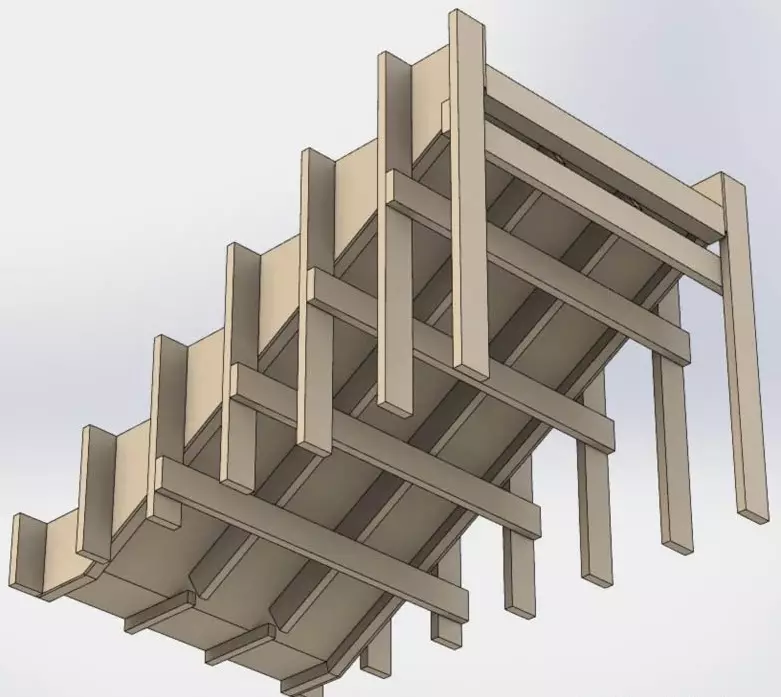

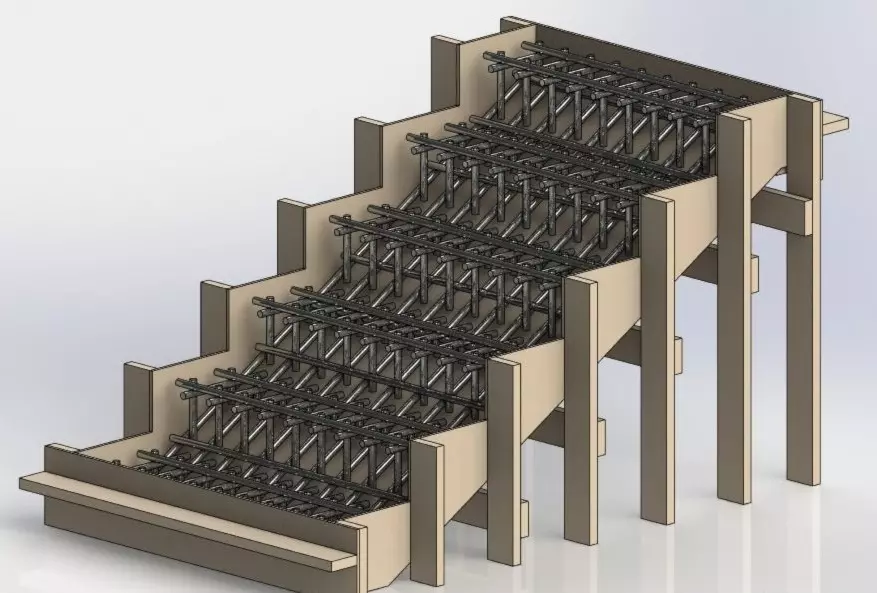

Step number 2 - assembly of the reinforcing frame and installation of formwork

Before pouring the stairs, the formwork is necessarily mounted with an accuracy of size shown in the diagram. It is the formwork that gives the necessary form of construction. And to give strength, carry out mandatory reinforcement.

To begin with, board are installed. Their rigidity on one side provides a wall, and on the opposite, boards are installed. Boards prevent concrete spreading and serve as the basis for which formwork is attached for steps.

At the next stage, the deck is installed, that is, the basis for concrete. Her role plays a durable sheet of plywood or OSP. Its thickness is 18-20 mm. At the bottom, the deck is fixed with a support for preventing the deflection under load. For supports use bars with a cross section of 50 × 50 mm or a 150 × 50 mm board.

Providing formwork, hold the basic rules:

- All attachments are performed only by wood screws, nails are not acceptable.

- The stability and strength of the formwork is the key to the fact that it will not crawl during the fill and the future design will be correct.

Article on the topic: How to separate the staircase in the house: Choosing a facing material | +65 photos

After preparation, the foundations are proceeding with reinforcement. Used to strengthen monolitha reinforcement with a cross section of 10-12 mm. They need to bind them in the form of a mesh with cell sizes 100 × 120 mm. The bundle is made with a special soft wire. Many experts reinforcement frames are welded, but this process gives the design of less reliability, since under load welding seams can be disturbed.

To enhance the steps and preventing the bugs, their edges conduct transverse reinforcement of elements. At the final stage, before the fill, it is established crossbars that serve as a formwork for steps.

The main rule during reinforcement: the valve should be located so that it is subsequently covered with concrete at least 4 cm.

On video: Nuances of framework for concrete staircase.

Stage number 3 - Pouring stairs

To fill the formwork with a concrete mixture at a time. Therefore, a sufficient amount of material is prepared. Otherwise, the monolith of the structure may suffer and the likelihood of cracks appears.

Pour the concrete staircase with a solution from the bottom stage. Moving is carried out on the edges of the formwork. The mixture is poured into each step, it is evenly distributed and thoroughly tram. The surface is leveled by a trowel.

After the concrete creates a bit, in the places of attachment of the railing in concrete, small wooden cylinders are immersed. At the edges of the steps, metal corners are pressed to prevent openings in the future.

After the day, the formwork is dismantled, and the surface is covered with cellophane. This will ensure uniform drying of the monolith.

Stage No. 4 - Finishing

The decoration of the concrete staircase in the basement of the house includes a device of the rail and decoration of the steps. Railings can be made of wood or metal. Although in the basement in many cases, the railing may not be installed. The surface of the steps is first thoroughly polished. Then, at the request of the tenants, they can be fed by ceramic tiles or install wooden steps.

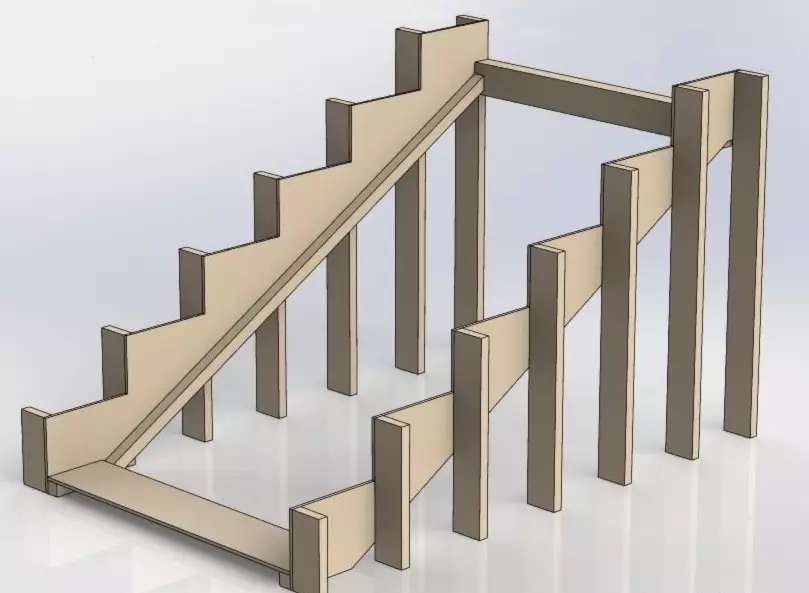

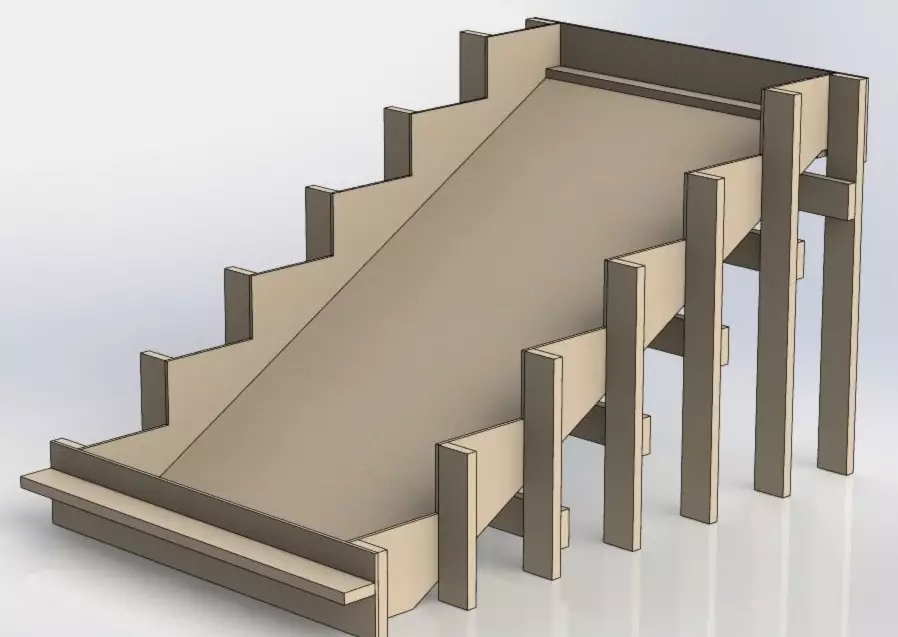

Installation of metal stairs

The staircase made of metal profile pipes in the basement floor can be mounted much easier than concrete. By weight, it is much easier. But the basement microclimate can adversely affect the metal, so they carry out full protection of the design from the appearance of corrosion.For the device of the metal staircase in the basement, you will need:

- Schawler number 10;

- Armature;

- Metal corners with dimensions of 50 × 50 mm;

- apparatus for welding;

- Bulgarian;

- steel sheets;

- building level.

Step No. 1 - Preparation of the Fundament

Preparation of the foundation under the iron staircase in the ground floor of the private structure can be performed in two ways. Both begin with an arrangement of a depression of 1 × 0.4 m and a depth of 0.5 m. At the bottom of the pits, the layer of rubble is poured. The further process is different.

In the first case, the concrete is poured, not reaching the edge of the recess 15 cm. Fully filled after installing the design to the base. In the second case, the concrete is completely poured, but the mortgages are predetermined. Their role plays fittings with a cross section of 12 mm. Ends should perform above the floor level by 25 cm.

Stage №2 - Installation of the stairs

Schwellers will act as a support on which the steps are fixed. They are fixed to the upper overlap with bolts at a distance of 0.9 m from each other. Their lower ends are installed on the basis and weld to the mortgage.

If you need to build a two-story metal staircase into the cellar, then the site is collected first. Square is welded from the channels in such a way that protruding edges remain from all sides. They will enable the workpiece on the walls of the basement.

Article on the topic: Optimal dimensions of stairs: Design a safe and comfortable design

To obtain full-fledged cosoms to the previously installed, the chapels need to be welded metal corners. Fastening is carried out on the inside. As a result, it should be what the photo below.

Stage No. 3 - Final Finish

After the design is completely cooked, proceed to her finish. Start with metal grinding. First of all, welding seams are grouped. Many masters perform this stripper in the process of welding. Then with light movements with a circle for grinding from metal elements, rust is removed. Purified design is completely covered with primer composition.

Next, proceed to the trimming of steps. For this, either leaf steel, or wooden boards. On the sides are welded railing.

On video: An example of the manufacture of a simple metal staircase.

Production of a ladder from a tree

On the installation of the staircase from wood in the basement of a private house, one should agree with the complete confidence that the microclimate in it will have a low degree of moisture. Otherwise, the product will last no longer. But even at the normal level of humidity, all protective measures should be carried out: to impregnate the wooden components by antiseptic substances and to cover with paint or varnish.For the device of the wooden staircase, it is necessary to prepare:

- beams for cososov;

- boards of 250 × 38 mm;

- anchor bolts;

- self-tapping screw;

- electrolovik;

- plane;

- grinding or sandpaper;

- screwdriver.

Step number 1 - Production and installation of cososov

Before installing the boosters should be prepared. From dense material (boards / plywood) cut out the stage of the stage according to the drawing. It is applied to the side of the beam and make the markup of the arrangement of the steps throughout the Kosouro.

Using the jigsaw, cut out extra parts. Cuts are spinning with a planer and cleaned with sandpaper. As a result, two identical Kouryer should be obtained.

Prepared boosters are installed under the necessary slope. The distance between them must correspond to the width of the finished design. Overlapping beams are fixed by anchor bolts. The lower part is attached to the base with metal corners.

If we are talking about a two-day staircase, the site is additionally mounted. Then the boosters are first installed from the overlap to the site, and then from it to the floor.

Step number 2 - Production of steps

Steps for the wooden staircase make pretty easy. The boards are cut on equal elements, processed them first by the plane, then grinding with the machine or emery paper. Similarly, you prepare vertical parts that are sewn steps.

Step No. 3 - Build Design

After the boosters are installed, the elements for the steps are prepared, proceed to the assembly of the whole design. First, the bakes are attached to the beams, and they are installed on them. All fasteners are carried out by self-drawing. The assembly should be carried out with constant levels of levels.

At the next stage, the railing is mounted. For them, bars are suitable with a cross section of 80 × 60 mm. Billets are cut 1 m long. All are cleaned and grind. You can give figure processing on the milling machine. Then the blanks are screwed to the steps, and on top of the handrail.

Figure balasins or bars are installed on wooden waders pre-delved in steps around the edges.

In conclusion, railing is installed. They are fixed using self-tapping screws. At this stage, the assembly is completed, it remains to be uploaded all the elements of the stairs and paint.

The staircase in the basement of the country house to equip with their own hands is easy. It all depends on the choice of material. The main thing is to correctly assess the situation, study the features of the microclimate in the basement. In accordance with this, draw conclusions about which design will be the most optimal.

Staircase "Goose step" - Compact solution (2 video)

Examples of stairs for basement and cellar (40 photos)