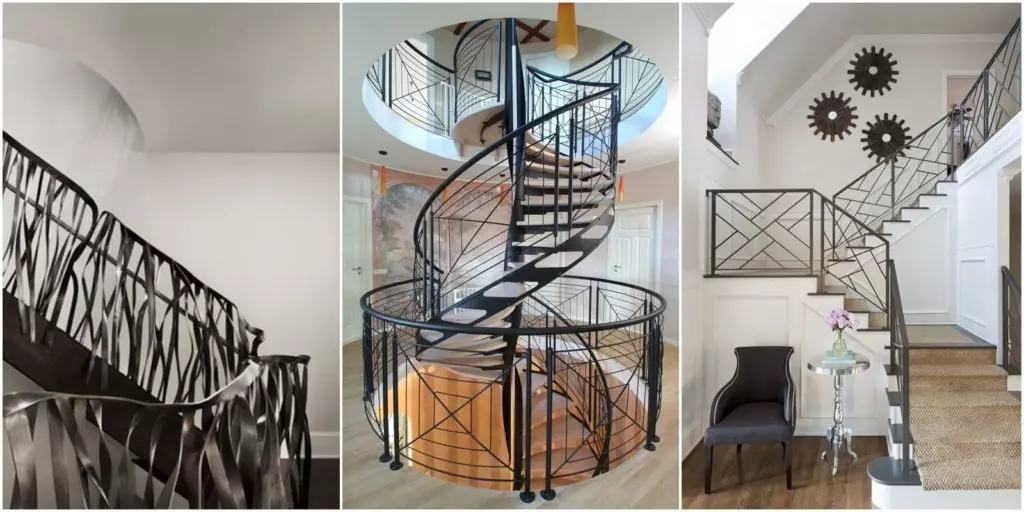

Art forging is a technological operation that allows you to maximize the use of all the benefits of steel - it is high rigidity, as well as plasticity. By the forging, ordinary stairs from ferrous metals are converted into real works of art, characterized by sophistication and monumentality.

With the help of artistic forging technology, thin and even air elements for stairs are created. The design will be quite rigid to withstand even serious loads. This is the popularity of wrought stairs to the second floor. Let's find out all about these products.

Features forged designs

For many hundred years, the technology of production of these stairs has practically not changed. Master-blacksmiths transferred knowledge and ability to future generations, but at least somehow automate the forging still fails. Therefore, coarse anvils, mites, sledgehammer and blacksmith horn are used for the manufacture of openwork elements from metal.

Since steel is a rather plastic material, then almost any images are obtained from it. And the inability of automation is only a plus, because the product, manufactured by hand, is estimated much more expensive and looks more interesting.

Another feature in universality. Forging allows you to get a really universal product. You can get a staircase in completely any styles.

Modern blacksmiths are able to work in such design directions as:

- Oriental;

- classical;

- Gothic;

- ampir;

- Modern;

- Baroque and many others.

Forged railing have a lot of advantages that even the most expensive breed of wood does not have. It:

- Visual ease of the product;

- transparency;

- durability and wear resistance;

- openness;

- high security;

- individual design.

Types of wrought stairs

Several main types of wroughtted staircases are distinguished. Choosing a specific type of envy on the following factors:

- convenience, comfort of operation and movement on the stairs;

- Financial capabilities and personal preferences;

- The presence of free space in the house.

For the complexity of forging the product can be divided into several types:

- Simple products. Here the forging is as simple as possible, but all the elements are beautiful. For the manufacture of the pattern, one type of material is used. This option is cheaper than all other things and such stairs are chosen only when the design requires a reliable fence.

Article on the topic: how to paint a wooden staircase: the choice of paintwork and coloring technology

- Constructions with an average level of complexity. Used mainly to create patterns with medium bends as minimal decorative decoration. This is more often street staircases, stairs for stores or hotels.

- Complex solutions. There is no fantasy limit here. Create any bend angles with the addition of a variety of scenes and inserts.

According to the functional purpose, metal stairs are divided into main, auxiliary, entrance and front.

In the video: wrought railing (about important trockers).

Movie

The most traditional and in demand are precisely the march stairs to the second floor. They provide the most convenient and most secure operation. Movie solutions just make. They are installed not only in private homes, but also in the interior of public premises, as well as in production sites.

In each march should be no less, but not more than 15 steps, then the rise will be safe and does not take a lot of strength. If the march is longer, it is divided into two or more parts, between which the playground is installed. Marsh structures can be both straight and turning. Despite some simplicity, they look interesting in the interior.

The only minus of such solutions is large overall dimensions, so they are rarely chosen for mounting in small houses or rooms with limited free space.

Screw

Screw stairs occupy a much smaller space and the product data looks beautiful. But in operation they are not so comfortable as the march. Feature in completely rotary steps. Space in a private house or apartment can be saved due to a spiralized design.

Forged screw solutions for a private house are chosen as an additional decoration. We use popularity with the arrangement of country houses with limited space.

Curvilinear

These forged stair systems are considered particularly complex in design and manufacturing, although decorative qualities are very, very high. May be both street and interior. Only masters of the highest qualification take them take them. The design is characterized by a semicircular shape. Stages are running out, having an upper platform.

Explicit advantages include high compactness and beautiful elegant design. Take a look at the photo of one of these stairs.

Making a wrought staircase

The manufacture of any staircase begins with the design and selection of the required material. But before you take for such work, you need to be sure that you can implement the entire technological process yourself. Of course, it is not necessary to do without skills to work with the welding machine, it is necessary and to know the exact dimensions of the future metal structures, depending on the free area and the features of the interior of the room, where the ladder will be installed.Article on the topic: How to make a staircase in a basement: the main stages of manufacture on three examples

Design

The production of forged products starts with the development. At the very beginning, you should work on the design and appearance. Maybe you will like an existing design, which is enough to make only minor edits for individual taste.

Also during the design, you can create sketches in different versions and then choose the most successful. Effective reception is a combination of successful sketches into a single project. Initially, everything is drawn on paper, and then select the most suitable elements and parts that form the pattern. If the forging process is performed with your own hands, the pattern must fully match the masters.

Too sophisticated elements may require the use of hot forging, which is difficult at home.

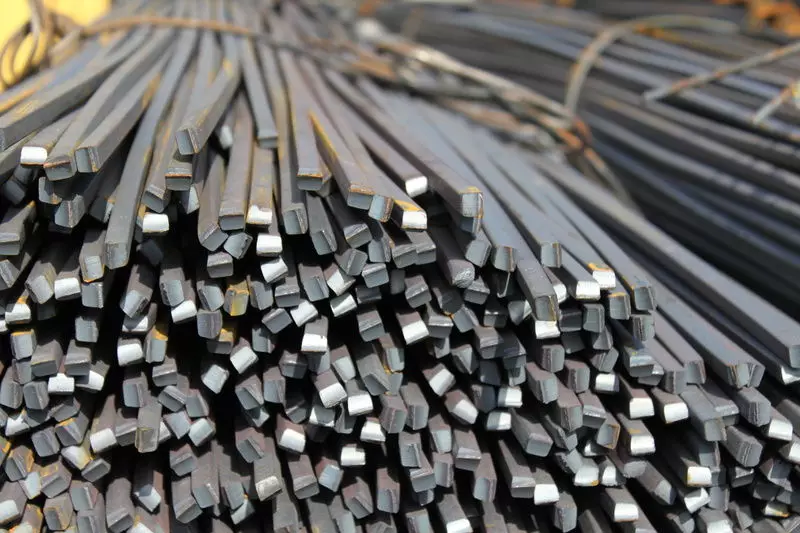

Selection of material

If the process will be carried out independently, then the material is calculated at the end of the designer work. For the manufacture of handrails for a wrought staircase, it is better to choose such a material that is easy to handle. Material profile, rental of various sections can be material for the implementation of ideas.

It is better to buy a small cross section for rent - it is easier to handle and is easier deformed.

In the construction of stairs, the forging is used only for the manufacture of railings, baluster, as well as close to these elements of parts. The staircase is the most common. It can be of wood, metal, from combined materials (when the carrier part is made of metal, and the steps are wooden).

Tool preparation

Before starting work, you should stock the necessary equipment. It will take:- Welding machine and consumables;

- flat place for assembly work;

- Bulgarian;

- level, roulette;

- pipe bender;

- Various little things.

Turning the surface

What happened on the sketch should be transferred to a pre-prepared surface. Initially draw a railing frame. The height standard for staircase is 950 mm. But it is necessary to take into account a small gap from the stage - approximately 100 mm.

Railings can be equipped with wooden handrail. Then the frame must be approximately 820 mm. Despite the fact that the dimensions are relative, in this case, accuracy is needed - the staircase spans have slopes. Even a slight change in the angle of inclination leads to the need for complete alterations.

When the frame is ready, tolerate the pattern. It is best to do in chalk to make it easy to erase and reinstall. When the drawing is fully ready, measure the length of each part.

Manufacturing design

When all sizes are known exactly, you can proceed directly to the manufacture. In size, it is necessary to cut the material, it is done with the help of a grinder. It is necessary to use the measuring instrument and not forget about the safety technique.

Article on the topic: Telescopic aluminum staircase - Mobile stepder for all cases

Each sliced piece need to give a form. It is quite difficult and can take a lot of time. It may not even work immediately, but it is necessary to continue to bring blanks into the shape of the sketch of the hammer. A mining will go faster, but at home is used cold forging.

When the blanks are bent, they are compared and test identity. Next, with the help of the welding machine, the frame is collected. When it is ready, it is filled. If the railing is from ready-made balusin, then you can immediately move to this item.

The elements are collected by patterns in the drawing. Each place makes small points with welding. It is necessary that in case of an error, the design could be easily disassembled.

Finishing Peril

So that the wrought staircase could become an interior decoration and was a functional and safe fence, each detail should be smooth. Otherwise, clothes will be clinging for burrs. The assembly places are cleaned with brushes and credit circles for the grinder.

Typically, painting is chosen as an external finish. But, before painting the ladder, you need to apply a special soil on it. The layer of the soil will contribute to the smooth layer of the Finish LCP. The soil will protect the metal from corrosion, if it is a street product.

To paint should be approached very seriously. It is often applied by a patina - it allows you to get beautiful effects. To give forged stairs in the house, the view "Under the Starin" is painted with paints with the effect of gilding. Painted products can be installed both in the house and on the street.

Cold forging: Railings for the stairs do it yourself (2 video)

Options for stairs with forged elements (55 photos)