Metal products were valued for a long time, and to blacksmiths who performed forged products were treated with great respect. It all became much easier with the large presence of a building material. Ready profile pipes are purchased and following the scheme, the desired design is welded. It is not an exception and a staircase from the profile pipe. Make it with your own hands is easy if there is experience with the welding machine.

Benefits of the stairs from the profile pipe

Machining a metal staircase, receive a number of advantages. It is in its functionality somewhat wins in front of wooden products or ready-made metal stairs.

The pluses of the profile pipe include the following:

- saving money and long service life of the ladder;

- the ability to descript and assemble the design of almost any form;

- excellent combination with other construction and finishing materials;

- small time spent on installation, but only provided that a master with experience works;

- the possibility of performing work and assembly of the structure at any stage of construction;

- the device of the staircase anywhere (both inside the structure and outside the building);

- You can cook a simplified version of the staircase, which visually takes less space indoors.

Some designs from profile pipes, welded by the latest technologies, as if soaring in the air.

Varieties

According to the masters, the staircase of any form can be constructed from profile pipes. Their list includes both simple designs and the introduction of the most intricate forms. When performing work, there are features. Consider them in more detail.Movie

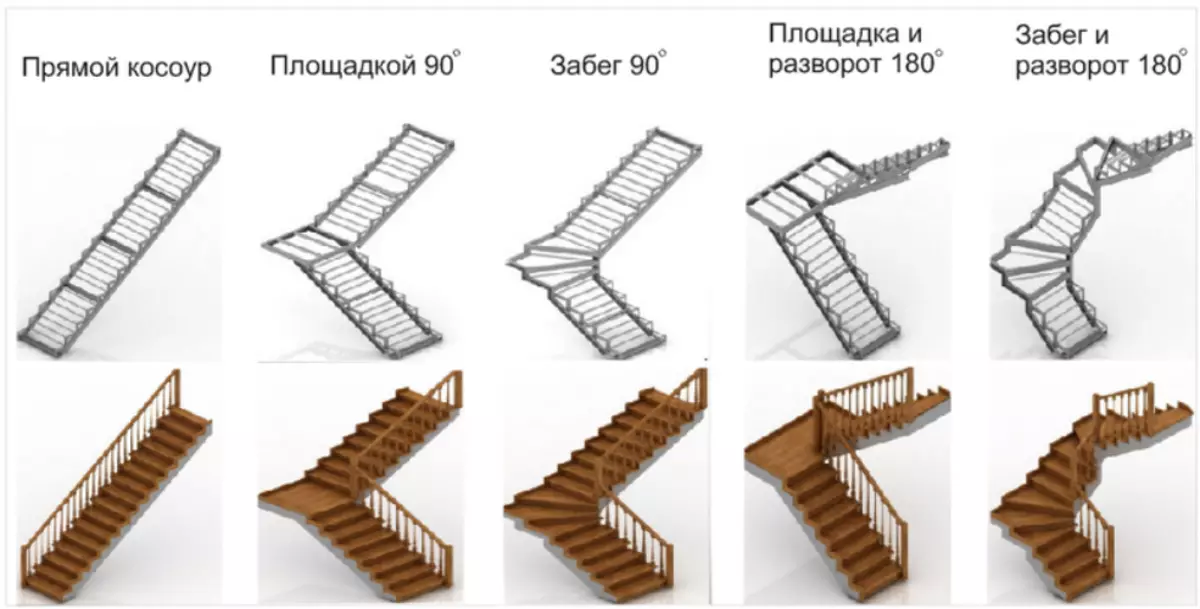

For the march stairs, the device is characterized by one and more flights. Products made of several marches are collected in one design with a platform of horizontal location or equip the steps of a running type. It is not necessary to talk about the demand of some kind of species. They are popular among consumers equally. Basically, the selection depends on the size of the area, assured for the installation of the staircase.

If the staircase consists of one march, it will take enough space for it. In the case when there is a lack of space, it will have to construct the product in this way to take as little space as possible. Many try to increase the steepness of the stairs, which leads to inconvenience when moving on it.

The ladder with a large steepness can only be arranged for the transition to the premises of the economic purpose.

Staircase with one march, taking the area indoors, allows you to rationally use the space under it. It is often equipped under the cabinets, niches or storage room. Also such products are installed at the entrance to the house. An appropriate type can be used to hit the attic.

In terms of saving space, two-page designs are installed. Most often installed in the corner of the room at the walls at right angles. Sometimes they make a turn at 180 or arrange three march. More convenient in the installation are stairs with a playground.

With overtime steps will have to tinker. But in defense of such structures, we can say that they look more attractive in design.

Rotary staircase made of profile pipes with running stepsScrew

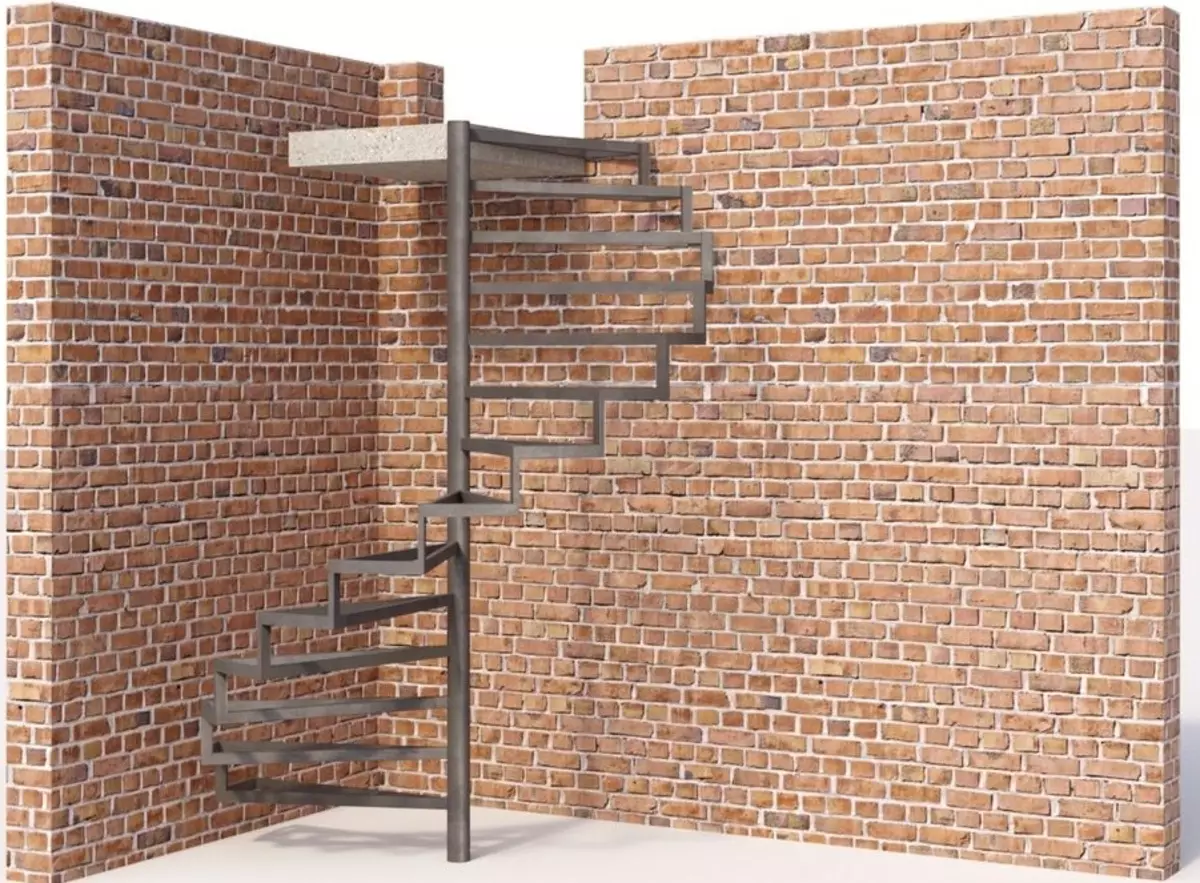

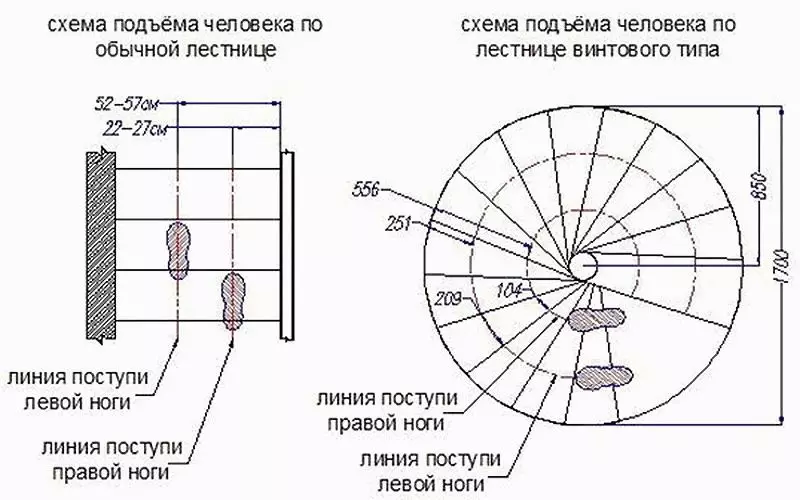

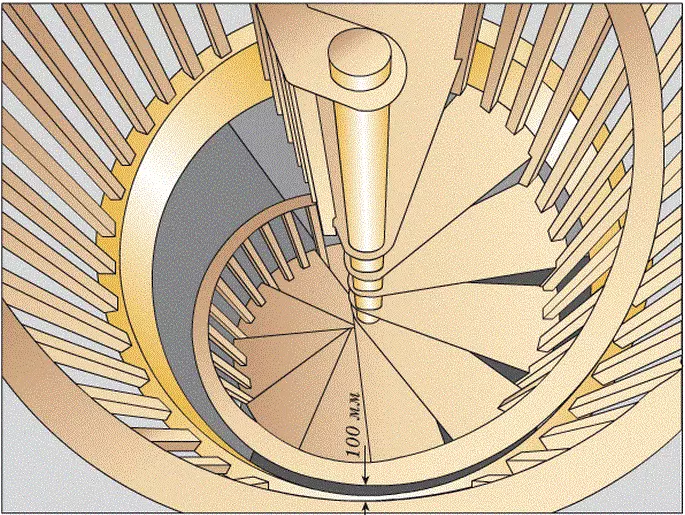

From compact options, the screw type of the staircase is marked. The appearance of its original and aesthetic, and enter the product, even on the space of 1.5 × 1.5 m. Such structures often have a central reference pole to which the steps are attached. The last with the edge can rely on the broken settlement or metal plates.

But despite all the advantages, there are cons of screw construction. So, the product does not allow to raise large furniture items. For the movement of tenants, even with empty hands is not comfortable. It is satisfied with the screw staircase only in extreme cases when there is no other exit.

There are difficulties in calculations and installation. It is almost impossible to perform such a ladder without definite experience.

If, despite the cons of screw products, there are adherents of this type of structures, experts advise closer to the project to a twilty type of several marches and expand the opening. In this case, use the screw staircase is much more convenient.

Article on the topic: Chair with transformation in the stairs: types of structures and features of independent manufacture

Stair-ladder

One of the variants of the device of the staircase from the profile pipe is a staircase ladder. If the tenants live in a private house, the folding staircase is one of the necessary products in the farm. Metal profile with a cross section of 40 × 40 mm for the manufacture of racks and 20 × 20 mm for mounting the crossbar, as well as hinged mechanisms, bolts and screws.

Hinges will make the design of the folding, and so that it does not disappear during use, is provided by stoppers.

For the installation of the stepladder with their own hands it is necessary to have tools and experience with them. Pre-drawn drawdown, allowing you to perform faster and more accurately. An example of such a scheme is presented in the photo below. A simpler version that can replace a ladder is an appropriate staircase from the profile pipe.

On the video: staircase-stepping out of proftruby do it yourself.

What do you need to know when calculating any staircase?

Calculations of the stairs from the proftrub are similar to designs from other materials. The process is not complicated, but requiring the preparation of the project. Be sure to indicate all the parameters of the staircase from the profile pipe in the drawing, the location of the corners and the slightest changes in the form of the product.

The main criteria that need to be considered when drawing up a project of any type of product:

- length of stairs or marches;

- march angle;

- The width of the span;

- The height of the riser;

- width of steps;

- Dimensions of the passage under the stairs.

Each type of stairs has its own features in the installation that must be considered when calculating and drafting the scheme.

Calculation of the marching design

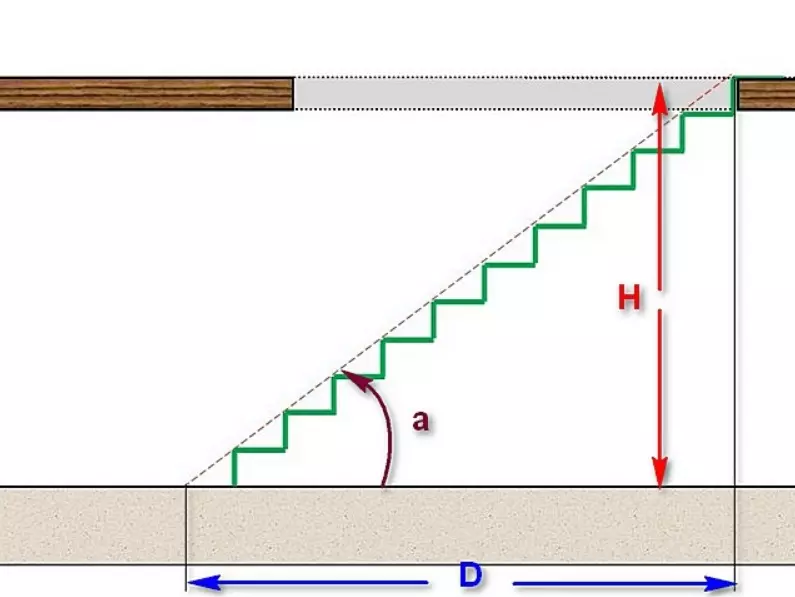

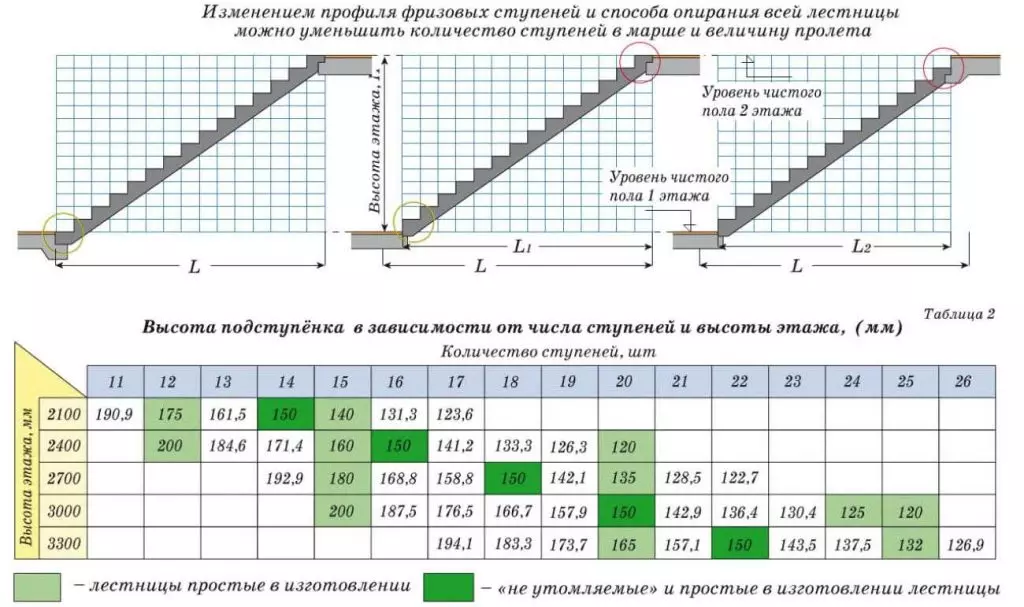

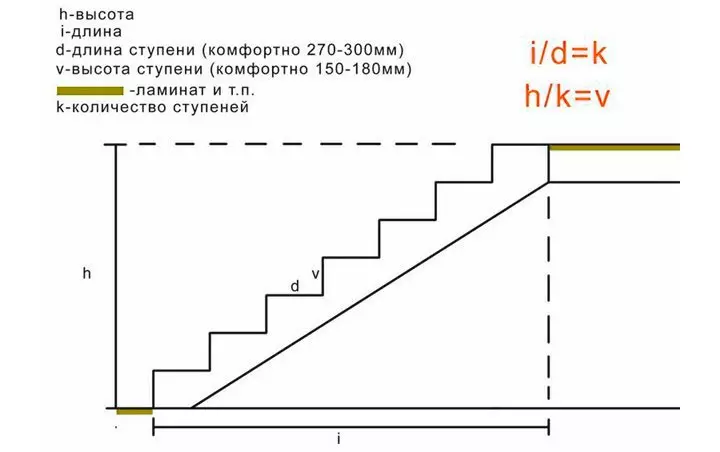

The calculations of the march staircase begin with determining the height of the staircase. Perform it easy. It is necessary to measure the distance from the floor to overlapping the upper floor.

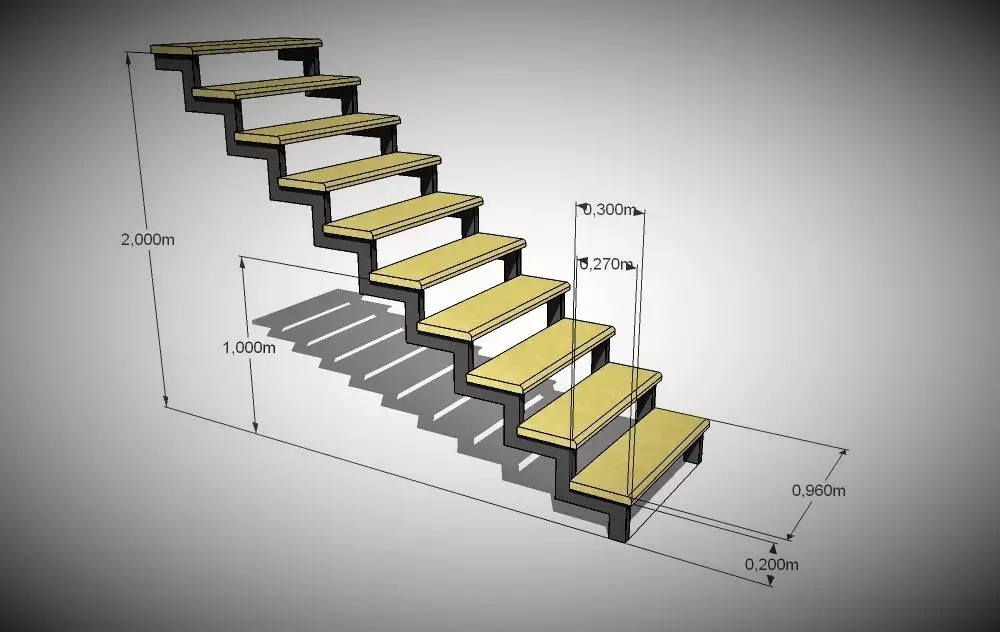

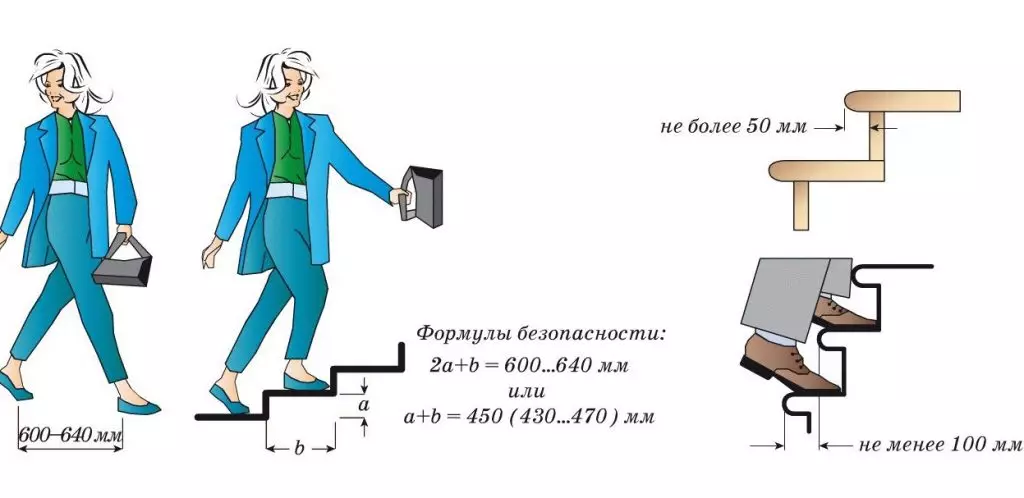

The convenience of movement provides not only the steepness of the product, but also the width of the stage, the height of the risk. Normal parameters are installed on both parameters: the stage size varies from 200 to 400 mm, and the risk - from 150 to 200 mm.

In practice, deviations often occur, but it complicates movement on the stairs from metal products.

Another important point is to comply with the proportionality between these values. It is necessary to calculate it according to the formula: a + b = 470 mm, where a is the height of the riser, the B-width of the sticking.

After determining the parameters of the sticky and the riser proceed to the calculation of the number of steps. To do this, the height of the span is divided into the height of the risk. Then the projection of the stairs is determined. Calculated by multiplying the width of the stage to the number of steps.

At home, the minimum value of the width of the span is 800 mm. When taking into account all the rules, a single-hour staircase with a ceiling height of 2.5 m has a projection on the floor from 5 m. Therefore, with a lack of place indoors, it is better to arrange swivel structures into several marches.

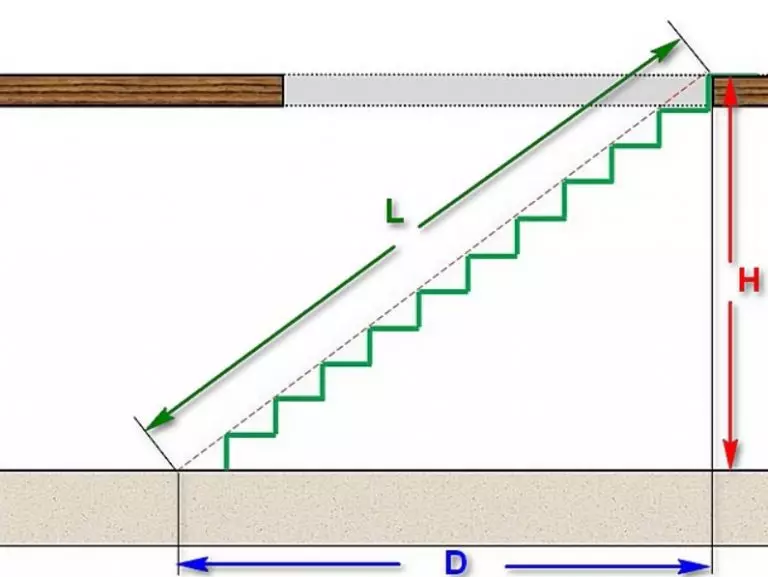

At the next stage, it is processed to calculate the length of the rower. Here the theorem Pythagora will come to the rescue. Cates are the height of the span and its projection on the floor. It is necessary to fold the squares of these indicators, and then remove the square root from the result. The resulting digit and will mean the length of the Kowra.

When calculating, no integers are most often obtained. Experts advise rounding them always in the biggest.

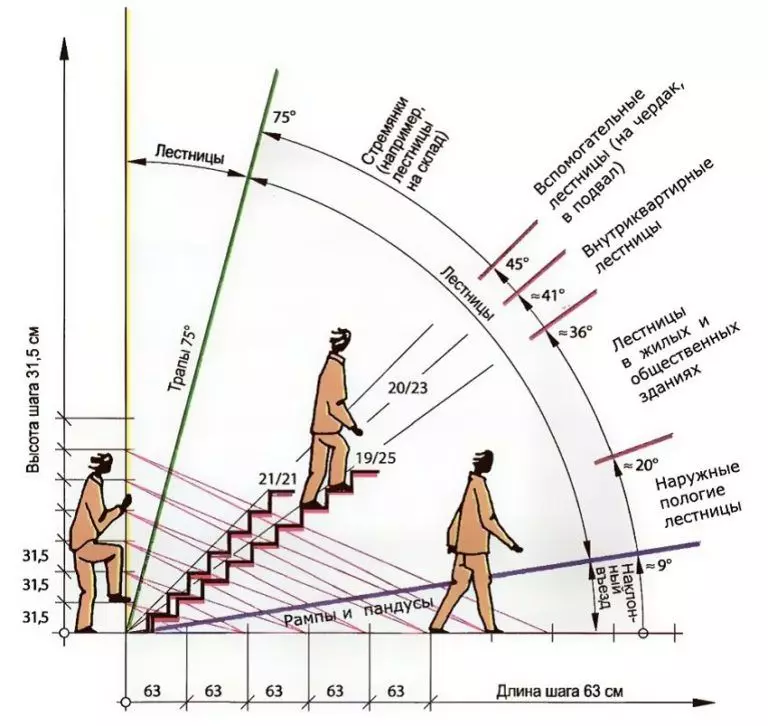

Another parameter that ensures the comfort of movement on the stairs, its steepness. According to all standards, an inter-storey device for permanent use should have an angle of inclination from 23 to 37. In practice, the maximum inclination angle can reach 40. The larger angle of inclination is suitable only with the palter stairs.

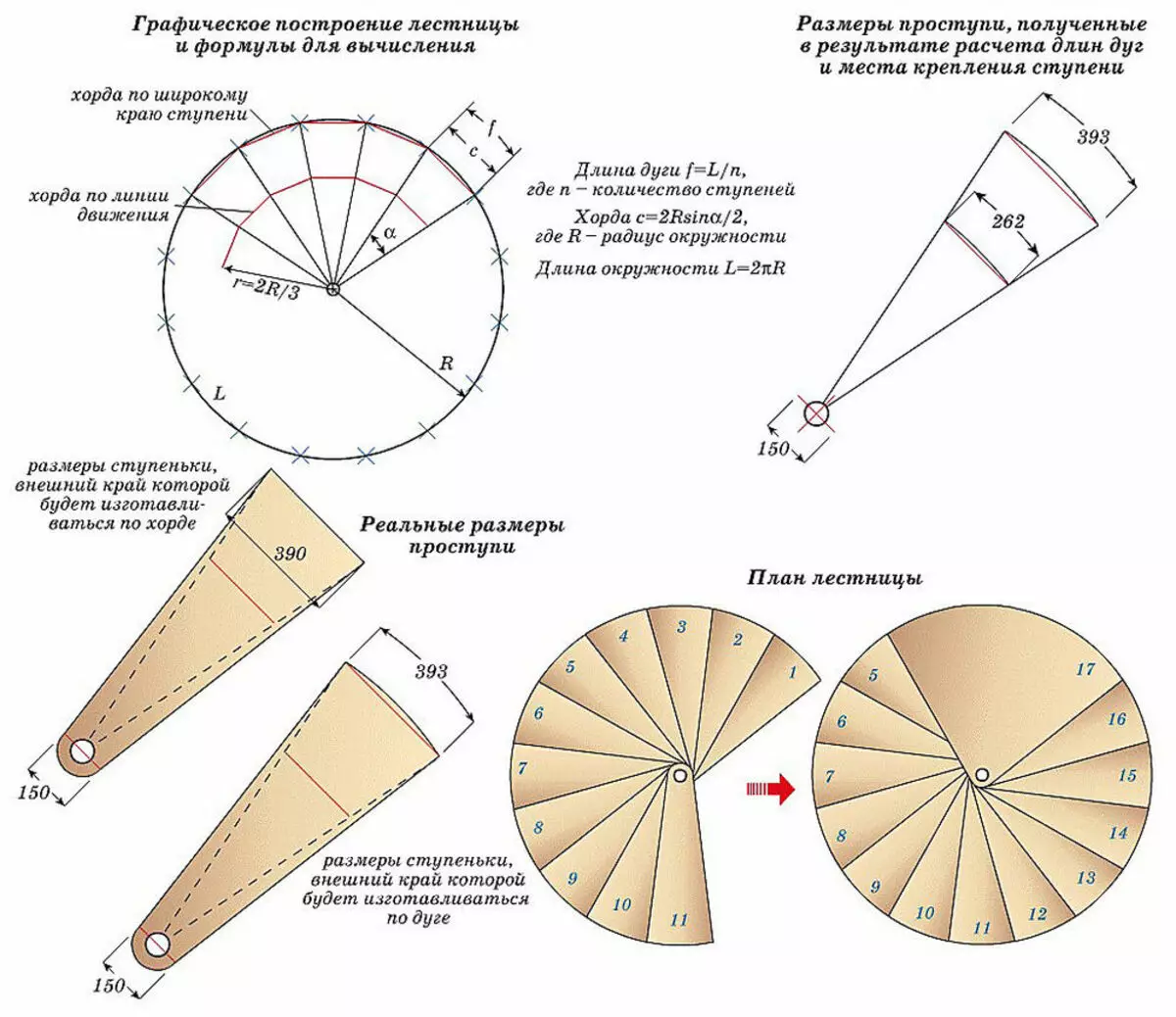

Calculation of the screw staircase

Rarely when a spiral staircase on the second floor from the profile pipe is arranged to maintain the designer solution. Often due to lack of space indoors. The costs of such a time and finance design significantly exceed the march.

Calculation of screw structures is best done using an online calculator, as they have a round shape. But, if there is a desire and experience, then you can calculate and manually.

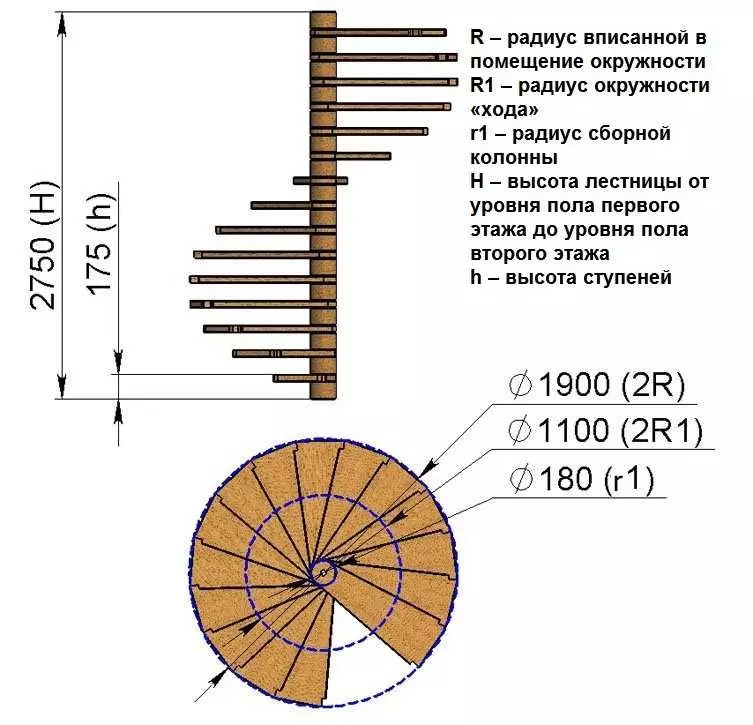

Initially, you will consider the names of the parameters that are used to calculate the products of the screw type:

- "H" - the vertical height of the product, the ceiling height plus the thickness of the overlapping is determined;

- "H1" - the distance between the turns. Implies a height between steps located strictly over each other;

- "H" - the height of the riser;

- "H1" - the depth of the stage;

- "R" - the value of the outer radius of the product, the perillion installation line;

- "R1" - the inner radius excluding railing;

- "R" - the radius of the central support.

Article on the topic: How to make a staircase with your own hands: choosing a type of construction, calculation of parameters and installation

Performing calculations are necessarily based on the installed norms for the screw design, presented below:

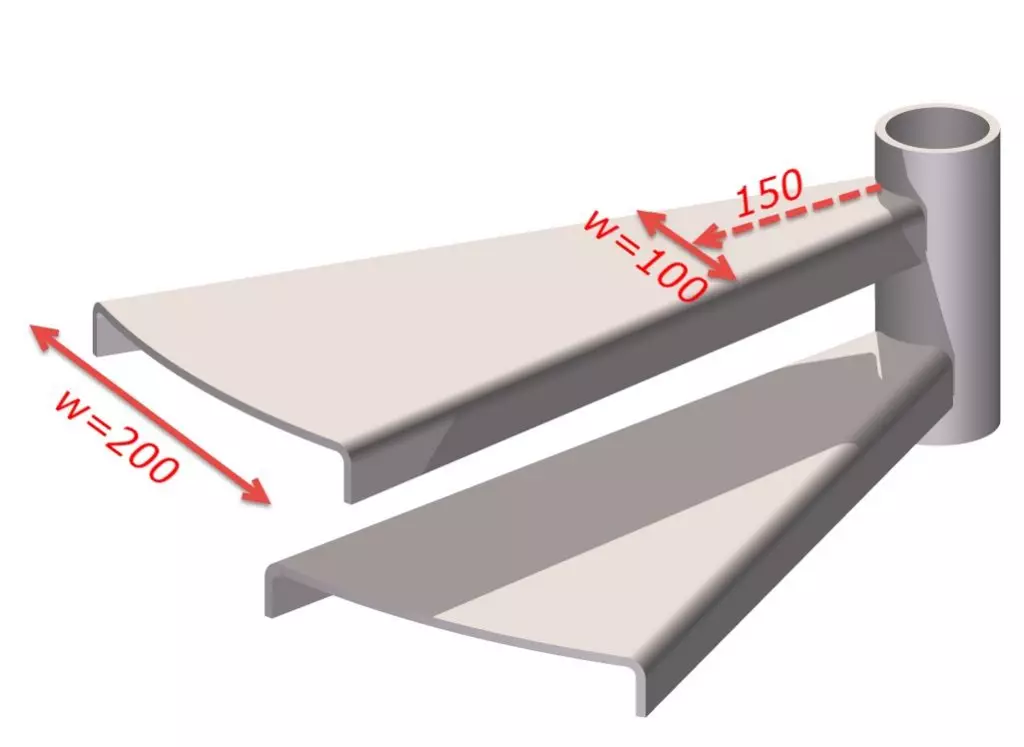

- In places passing the line of the working radius, where a person usually puts his legs, the shredding depth should be 200-400 mm.

- The depth of the stage in the support (at a distance of 10-15 cm from it) should be at least 100 mm. The height of the riser varies from 120 to 220 mm.

- The minimum value of the width of the outlet for screw structures is 100 cm, in the absence of perill - up to 150 cm.

Any calculations begin with measurements. It is necessary to correctly define the parameter of the external radius, the height of the structure and the location of the input and output points, the so-called spinning angle. Then proceed to calculations.

An example of calculating with "R" = 1 m, "H" = 3 m, with a twisting angle of 360 is given. With these values, the length of the working march is determined using formula 2 * n * R1. It is usually 2/3 from the value of the outdoor parameter. According to the data presented, 2/3 * 2 * 3,14 * 1000 = 4190 mm = 4.19 m will be obtained.

At the next step, the number of steps along the main formula N = L / H1 is calculated. We define the values of "H1" = 250 mm and we obtain 4190/250 = 16.79. It is necessary to round down in a majority, in the end we get 17. Taking into account the fact that the last step corresponds to the level of the floor of the second floor, then the individual elements we get 16.

The smallest width of the stage at the base is 100 mm. Calculate value in the widest place. To do this, first determine the length of the external march according to the 2PR formula. After performing the calculations, we get 6280 mm = 6.28 m. Dividing the resulting value to the number of steps, we obtain 6280/17 = 369 mm.

The calculation of the height of the risk is performed by the same principle as for the marching structure. The height of 3 m is divided into the number of steps, as a result we have 176 mm. Optimization of dimensions is carried out according to the formula 2H + H¹ equals from 600 to 650 mm. After conducting correction, we obtain the result of 190 mm.

Build construction

Having coped with the most difficult task, with the calculations, proceed to the markup of the profile and the creation of the frame in the drawings. This process is simple, so they go directly to the welding of elements from pipes. Some prefer to connect on fasteners, but it is much more difficult and takes quite a long time. Let us look in detail how to cook the staircase from the profile pipe.

Collect the marching span

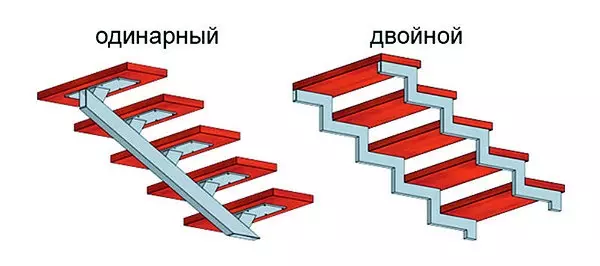

Installation of self-made march design depends on its type:

- fastening on one reinforced professional trade;

- Welding elements and education of broods.

On one profile pipe

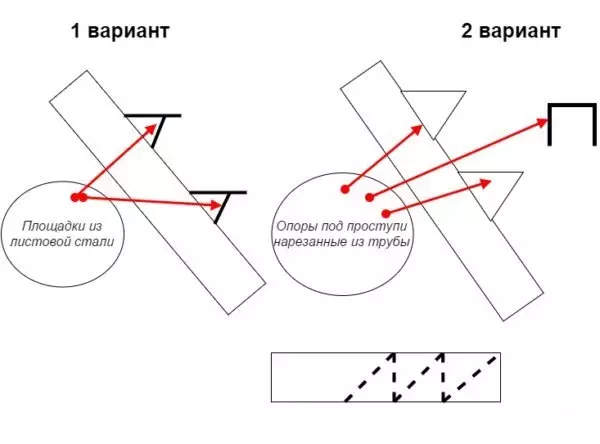

For the first option, it is necessary to purchase a proftrubube with a cross section of 150 × 150 mm. It will ensure reliable strength. For coming, it is necessary to ensure support. The sheets of metal 3-4 mm are in their quality, the width of which should be ½ the values of the sharpening in the diagram.

Cooking coasters for steps on a pipe can be in several ways:

1. In places of fastening, the steps with a certain step are welded in advance prepared sheets, serving stands for steps. But on one welding seam, the elements will not stand the load. It is necessary to provide them with a backup. Its role can play pieces of reinforcement from the same sheet or a smaller profile. But experts note that aesthetics of such a staircase is not at a high level.

2. The design of the second option is much more attractive. For starters, the details of the support from the same pipe as the carrier part are cut. One of the ends is cut at the angle of inclination of the stairs. In this place, the support is welded to the base. From the second end, plates are welded for steps.

Article on the topic: Benefits of transformer stairs and their varieties (popular manufacturers)

The load on the staircase is considerable, especially at the point of touching the main pipe to the floor. You need to distribute the load evenly. At the touch of a supporting tube with overlapping, you need to screw the plate of metal with a thickness of 5 mm.

The dimensions of the plate should be slightly larger than those that were used for supports under the step.

On broken crouches

The following version of the frame staircase from the profile pipe is a broken march, replacing beams in wooden products. Its pluses include low cost and low weight, if compared with the product on one pipe. Pipes are purchased with a cross section of 40 × 60 mm. It is allowed a little more, but no less.

The welding of the framework is also produced in two ways:

1. First, the billets corresponding to the scenarios and the riser with the addition of the thickness of the material are cut. Then the sequential elements are welded at right angles and get ready-made Kosur. The disadvantages of this method include bulky work on welding and the possibility of an uneven compound.

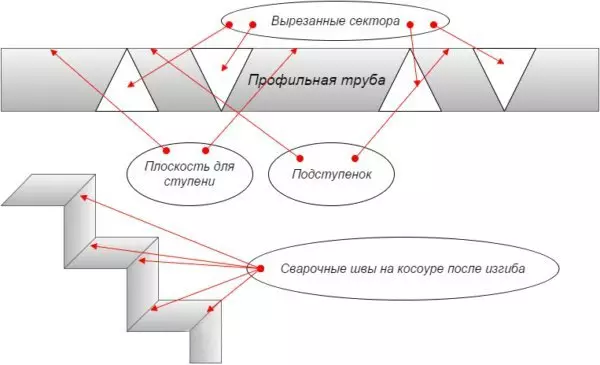

2. The second method of welding more aesthetic and refers to one of the lungs. It is necessary in the pipe on one side to cut the brine, the part in the form of an anose-free triangle. One side of the material remains not touched. After that, the pipe bended to the formation of a straight angle, performing the joints.

The supports for steps are obtained as a result of welding the upper corners of the cosos among themselves with a smaller tube.

Screw assembly

Installation of homemade spiral staircase starts with the installation of the pipe-support strictly vertically. Its role should serve the part with a round cross section and as much as possible thickness. This is justified by a huge burden on it. On the floor at the base of the support, the thick and reliable platform is installed. During construction work, a cross is welded and poured by a concrete tie.

Next, go to the supports under the step. They can also be made in two ways, depending on the cross section of the profile tube:

1. From metal-mill with a cross section of 20 × 20 mm or 30 × 30 mm, parts are welded. There should be a form that repeats the perimeter of future steps. In order not to suffer with fitting to the size of each detail, you can pre-make molds. From wooden bars, the desired form is formed and attached to the plywood sheet. It remains inside inserting metal segments and weld them with each other.

2. For the second method, pipes with a cross section of 40 × 60 mm are purchased. For welding, elements equal to the working radius are cut. For each of their end, parts are welded with the same cross section and a length of slightly less than the sizes in the form of a literature "T".

After preparing supports, they are welded to a round-based staircase in the locations of the steps according to the project. For greater reliability, the support of the steps is reinforced by the backup attached to the base.

Finishing work

The frame of homemade staircase is ready, and it's time to do an external finish. Most often for this tree use. Wooden elements for steps are selected with a thickness of at least 40 mm. To reflect the lateral part of the product and use material with a smaller thickness for risters.

To protect the profile pipe from corrosion, it is first cleaned from dust and dirt, the welding space is cleaned with a file. Degreased, soaked and apply paint in 2-3 layers.

In the case when the installation of the stairs is planned to be performed independently, then the option with profile pipes is optimal. The process is much easier than with wooden structures, and reliability is significantly higher. Following the recommendations presented in the content of the article, the output will be reliable, firmly installed staircase from profile pipes.

Examples of framework for the staircase (3 video)

Different types of stairs from proftrub (50 photos)