Due to the fact that most of our fellow citizens, when the internal decoration of their apartments uses drywall sheets, one important problem occurs - how to make an outer angle of drywall smooth and beautiful?

Installation of angular design

Perfect geometry of space

Difficult drywall structures - such work deserves admiration!

Undoubtedly, plasterboard is the most popular material for the interior decoration. But in order to make sure to master the skill of the installation of GLC, it is necessary not only to "span" sheets on the wall and collect the frame from metal products, but also work with more complex designs and connections, such as corners.

Hypzart's corners are both external and internal. Now let's try to figure out the technology of their manufacture in more detail.

Collect external angles

Installation of outer corner

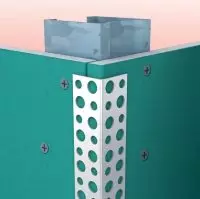

Among the design features of this type of corner, I would like to note that there is no connecting frame for drywall. For its manufacture, you need to take two rack profiles and insert them on both sides of the wall. Next, you should attach them to the perimetral profile using self-samples.

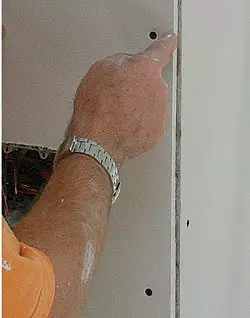

So, after you secured drywall sheets, you must move to the finishing part of the entire process. To do this, remove the chamchair at an angle of 45 °. Then, after the chamfer removal, all the slots and joints are applied, glue a plastic corner for drywall.

The resulting design will be not only beautiful and smooth, but also tough. You ask - Be sure to make a chamfer? The answer is yes, this type of work is performed necessarily.

Remove the chamfer

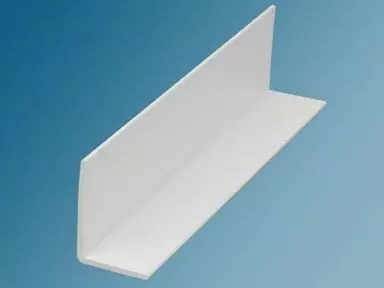

Why do we use the plastic corner for drywall?

- The resulting recess (previously removed chamfering allows plastic corners to go well and be imperceptible under a layer of putty;

- When installing a plastic corner, largely improved the adhesion of the two sides of the GLK (you cannot break them, accidentally tailored, they will not crumble).

Article on the topic: Mount GVL on the walls: phased instruction

Plastic corner

Collect the inner corner

In order to get a high-quality, durable and reliable inner corner, you should know several rules for the treatment of such material as GLC.It is also very important to know how the inner angles are mounted, how to sew the angle of plasterboard and, finally, one of the most important things to close the inner corner so that it turns out to be smooth and beautiful. In general, they are mounted quite easily, you only need to get acquainted with the main stages of installation.

Tool

- Metal PS profile or CD for plasterboard;

- Plasterboard sheets;

- Self-tapping screws (9-9.5 mm);

- Screwdriver;

- Scissors for metal;

- Bruks (in the event that you use a wooden frame, and not metallic).

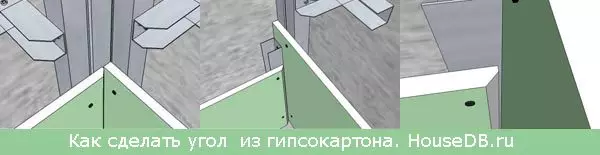

Installation of inner corners

Visual mounting

In the place where it is required to make an inner corner, kpripim profile. As a rule, everything is already ready on one of the walls (the frame is already trimmed with plasterboard and put putty works).

It turns out that we simply make the second part of the wall.

To sort out how to make an angle from drywall, consider all stages of work in order:

- Initially, we need to make a frame for a second wall (a metal-plastic or a timber) is used). For this, we need to install the guide profile on the floor and the ceiling (the main thing is that they go parallel);

- Next, we set the vertical profile, with an average distance from each other in 30 cm;

- The most important thing is not forget to bore the frame and the finished wall of each other (so you can greatly increase the strength of the whole design);

- If you make an inner corner in the area of the doorway or arch, it should be used as a linking of an angle, but two profiles. As a result, we obtain a framework in which our corner is reinforced by two profiles bonded with each other self-draws;

- After the frame will be finally ready, you can move to the cover of the GLC sheets of the resulting design.

Do not forget about the chamfer! It also needs to be removed from the edges of the GLCs, as in the case of external corners;

- The next stage is to prepare for the shtlock. To do this, you will need a construction tape that will need to sample all the slots and connections;

- Plaster. Here you will need a special putty for drywall and Kelma for the corners (the spatula is exactly lost the corner quite difficult). The entire work surface must be lured until a uniform and smooth coating is obtained;

Article on the topic: Benefits of the sheet of painted galvanized

Corner finish

- After drying the plaster, you need to walk along the surface with a special grinding net, which will help eliminate all irregularities.

Tip!

If you are not satisfied with the hardness of the angle of the corner, and you do not know what to do - there is a solution. Installing the corners on plasterboard will help solve this problem, and at the same time without adding you extra work!

Plastic corners

Plastic element for external corners

Installing this element is a fairly simple type of work that can be done even with your own newcomers. In general, corners are applied not only to strengthen and align - if you choose in favor of decorative plastic, it will serve as an excellent decoration for doorways and niches, as well as decoration of the arches and podiums.

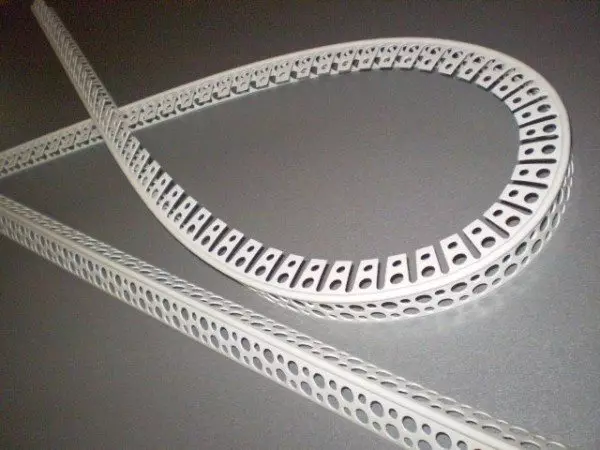

Plastic corner for arched structures

In the event that you install a plastic corner as a linking of an inner or outer angle, it will perfectly stay on a special putty for GLC. If you decide to use ornamental models, it is customary to use liquid nails (mounting glue) as fasteners.

Corners for drywall - there are both plastic and metal and are an affordable and inexpensive element of plasterboard structures. The price of plasterboard corners is not high (something about 50 rubles per piece), so everyone can make themselves high-quality and durable drywall structures, not experiencing about serious expenses.

Let's sum up

As expected, there is nothing complicated in the manufacture of external and inner corners - it is enough to have a necessary tool and material at hand. If you have any questions, our photos and video instructions will help you find a solution to those who have arisen.