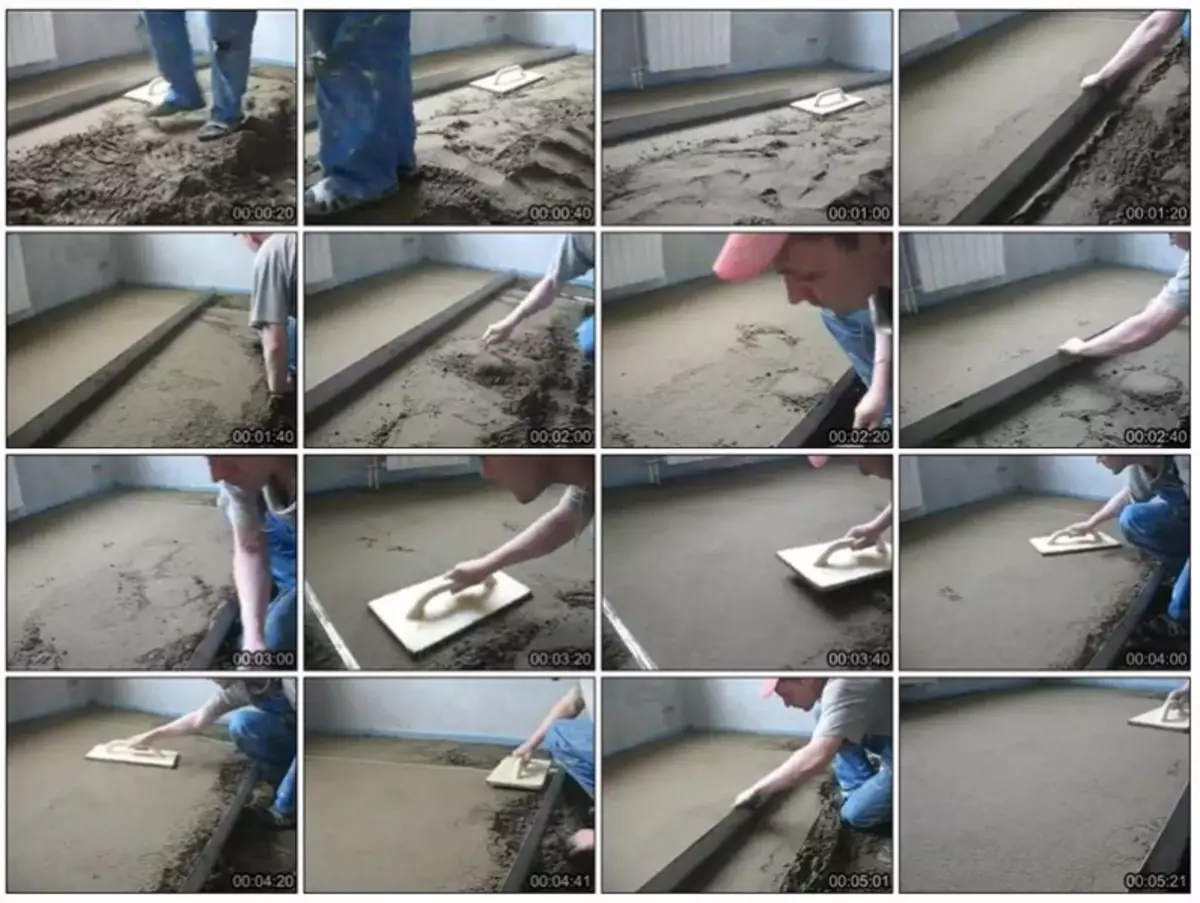

On the video, the semi-dry band screed is performed with their own hands quite simple. And this is not seeming ease. In fact, create such an option of a screed is quite simple, if you act correctly, execute instructions and apply high-quality materials. And the blacknovaya screed of the floor on the soil plays an important role.

Main advantages

The semi-dry screed has several objective advantages, among which the following can be distinguished.

- Repaired fast drying. This is the average variant between the wet and dry tie, which takes 3-5 days.

- High durability. Additionally, the surface is reinforced with a mesh or polypropylene fiber.

- Availability. To create such a surface in a private house, the apartment does not require expensive materials.

- Lack of additional processing. When a rough screed was performed, to align, it is not required to moisturize the surface. The finishing surface requires minimal costs.

- Creating a reliable, durable, smooth surface that will not suffer from cracking, shrinkage. It is not rarely stacked right on the ground, over the Earth.

- Relative simplicity performed by your own hands.

- Waterproofing, sound insulation and thermal insulation properties.

Make a semi-dry clip on video instructions is not difficult at all. Therefore, before making screeds on the floor, we recommend to familiarize yourself with the visual manuals and examples of work. If you quickly figure out how to make floor ties, for you this stage of repair will not be a problem.

If there is a screed of the floor with their own hands, make sure of your qualifications, in order not to redo all the professionals. When there is a finishing screed, resources for updating the draft will need a lot. In fact, you have to start everything from scratch. You definitely do not want. Therefore, when preparing the floor, do everything according to the instructions.

Application area

Semi-dry tie can be found in the apartment, a private house on the soil or rough base. This option is used in such cases:

- A tough limit on the timing allocated for floor repair in a private house, an apartment;

- Thin overlaps between the floors;

- High likelihood of fluid leaks on the lower floors.

Article on the topic: Putting the tile in the toilet

Before you correctly make a half-type flooring, it will not be superfluous to learn about the basics to which it is applied.

- Wooden overlaps. They may be present in a private house or an old sample houses.

- Concrete floors. They can be found everywhere in high-rise buildings.

- Right on the soil. It is the rammed sand, ground of gravel and sand. Pouring on the soil is performed in basements, a private house, on the first floors.

Preparation of solution

If you do not know how to make a half-type floor screed, be sure to get acquainted with the features of the preparation of the solution. The principle of preparation does not depend on whether it will be pure or rough styling, in the soil or concrete base.

But consider, if you wish, provide a screed with additional heat insulating properties, in addition to the standard set of components, you must include:

- Edge ribbon;

- Sand;

- Anticoned grid;

- Water;

- Cement;

- Fibrovolok;

- Elastifiers, hardeners;

- Self-determined solution or tile glue;

- Claimed waterproofing material (type of rubberoid);

- Foamed polystyrene foam or mineral wool for insulation.

Now directly about how the semi-dry band is preparing with their own hands.

- Push up in the pneumatic stepper 120 liters of sand, 150 grams of fibrovolock and 50 kilograms of cement.

- On 20 square meters of the area, 540 grams of fibra are required.

- Components are kneaded 3 minutes.

- Add water, mix another 1-2 minutes.

- If a grid for reinforcement is used, portland cement 400 is added to the solution and the scene sand in a ratio of 1 to 3. It is not necessary to prepare a mixture in a mixer, you can do it in place. Then the water is added gradually, but in small quantities. The solution is cooked correctly, if it is easy to generate in hand, water does not flow.

- Add the elasticizer to make a screed plastic, heat-resistant.

Making a screed

To make your own hands to make a semi-dry screed on the soil or on a wooden, concrete base in a private house, several consecutive operations should be performed.

- Remove the room. The rough base is prepared carefully by removing old finishing materials, garbage, furniture;

- Prepare the surface. There is no need to do anything on the ground, except for the ramp. If the surface on the floor in a private house is made of concrete, wood, then it needs to be projected or filling with special glue. It is important to achieve a smooth surface;

- Place the damper tape. It will be required both with a simple floor repair, and if desired, then lay a warm floor system. The tape retains the integrity of the screed, provides additional sound insulation;

- Put the solution. The first layer on the floor in a private house on the ground is laid by a layer of 20 millimeters. Miss it as it should, put the reinforcing grid on top;

- Metal grid must connect wire or connect with welding;

- See about 30-40 millimeters with your own hands on top;

- If there is fibrovolok in the solution, it is not necessary to strengthen the floor of the reinforcing grid to the ground;

- Align the surface. Alignment is performed by a laser level, beacons, rule;

- Grout. The semi-dry screed will require grout using a grater. It is necessary to do this with a partial frozen solution. Taking the lighthouses, fill them with a solution and stabbing. For these purposes, you will need a grinding machine;

- Care. Having finished with your own hands the screed, be sure to cover it with a film to prevent too fast drying. After 4 days, the semi-dry screed is completely formed, you will be able to start laying a finishing floor, a new floor covering.

Article on the topic: How to cut the ceiling plinth in the corners

We figured out how to make a tie of semi-dry type with your own hands, but for clarity we advise you to watch training videos. Semi-dry screed has a number of advantages and features. Plus we guarantee sexual coatings evenness and durability. But make sure that it is suitable for your case.