A feature of the work on finding pools is the need to take into account the conditions of operation of the coating. The tile must withstand water pressure and constant contact with it. A special requirement is the choice of laying materials.

The glue for mounting tiles in the pool is selected separately. It is distinguished by a special composition and water resistance. Preferably we are talking about polymer ready-made mixtures. In addition, it is worth considering that the mass remains elastic even after frozen to compensate for the load and deflection of tiles. Grout must be waterproof to ensure reliable waterproofing of the base.

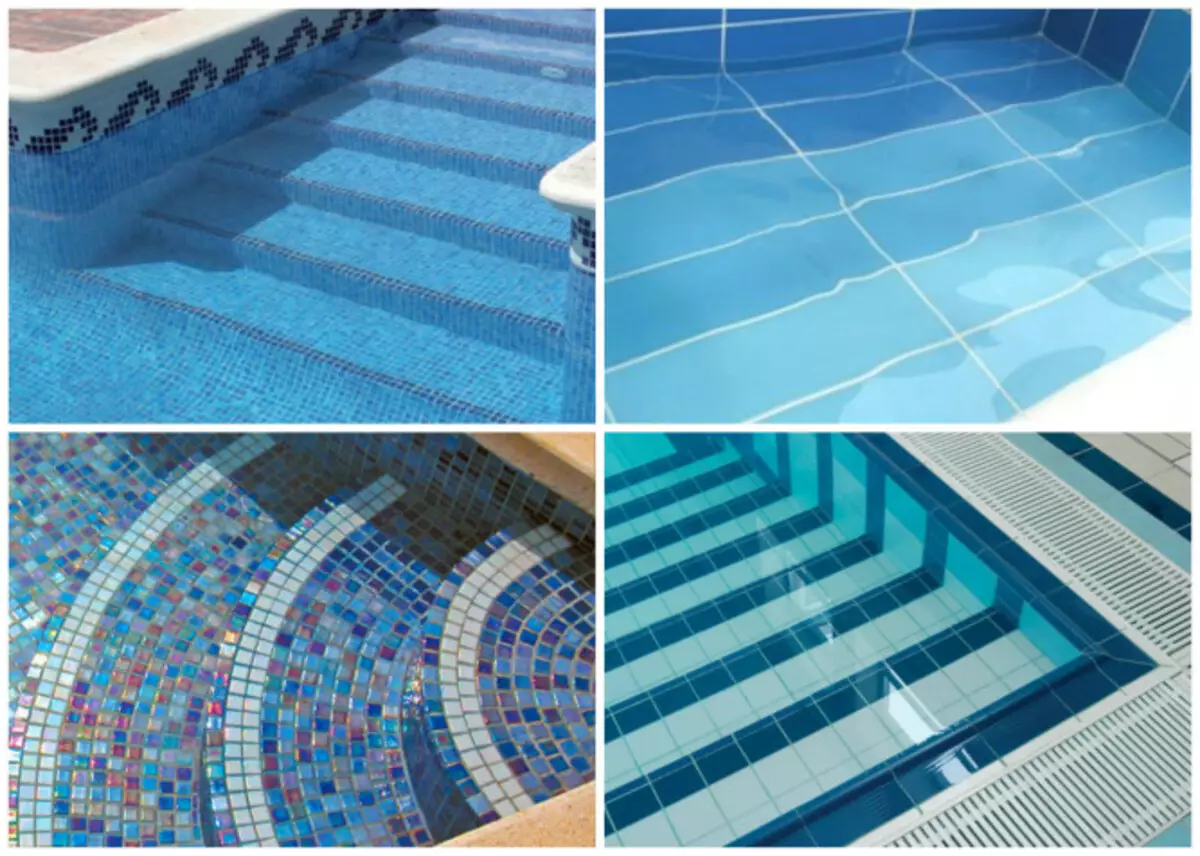

Facing can be combined. For example, the bottom is laid out the cafeter of different colors, noting the drops of depth, and the walls and adjacent floors - mosaic. Recreation area is also tiled. The choice depends solely on the project designer.

Traditional blue-blue tones

Base

When preparing a boiler for the styling of tiles, two main directions are performed: waterproofing and alignment. This will create a smooth coating and prevent the destruction of concrete under the influence of water.

Consider the surface leveling process. Most pool are concreted recess or separately standing bowl. In order for the facing coating to be flawed, and the glue was consumed at a minimum it is necessary to bring the basis to the ideal. For alignment, different compositions are used:

- Concrete. This is a rough coating that removes rough irregularities. In the structure of the cast form of the pool, there may be flaws, for example, depressions or cracks remaining after removing the formwork. It is them that is removed by repeated selective concreting.

- Cement plaster . It is designed to equalize the surface of the walls of the pool and its bottom. The mass is applied with a spatula after pre-priming. It is better to use waterproof formulations.

- Polymerized spacure . This is a final layer, which is optional. Due to the presence of modifiers and polymer impurities, even small deficiencies are removed and additional protection against water.

Article on the topic: Ideas for storing vegetables, bike, skis and other things on the balcony (30 photos)

Concrete Pool Surveillance Technology

Immediately the waterproofing itself implies the use of film and liquid bitumen materials. With their help, moisture is excluded in the structure of a concrete base. Shakes and seams are carefully soothed. Initially, the film material is placed, which is most often filled with a screed, on top of which bituminous or other mastic in 2 layers is applied.

Another additional insulator will serve the glue.

Only after drying the concrete and plaster, with antiseptic and primer processing, tile laying is made.

Choosing facing

Now the material itself comes to the fore. First of all, it is associated with the specific design. To compensate for the pressure of water to the coating, the tile should be simultaneously durable, but also flexible. The first depends solely on the tile itself.

If we talk about a mosaic, it is better to give preference to glass samples. Ceramics can also be used, but it's better to give up from the coarse stone. Mosaic is an excellent option.

If you prefer to use a tile to cover the pool, give preference to porcelain models. Due to their composition, high-quality waterproofing is ensured and the development of fungus is prevented. Due to the complexity of the facing surface, it is better to take samples of small sizes.

Options in classic blue colors

Facing the floor around the pool, descent to water and steps is made with a rough surface material, for example, some types of porcelain stoneware.

Traditional colors are all shades of blue, blue, white and green. Often there are more rich options, for example, black with red or gold. What a tile is best suited to solve you or your designer.

So that under the pressure of the water, the finish does not crack, it is necessary to pick up good glue. A prerequisite must be the content of latex or other polymer particles to prevent moisture passage. Another important criterion is elasticity. Such glue, even after drying, retains the ability to deformation without the destruction of the layer structure. This compensates for the deflection of the material under the load of water.

Article on the topic: Curtains from organza photo

Installation of tile

Pool cladding technology tiles of special differences does not have from classic surfaces. The only significant nuance is the complexity of work. The tile in the pools is usually stacked according to the standard suture scheme in the seam. Marking is applied for convenience. This is especially true when selecting zones with bent lines.Laying the bottom is made from the center. It is necessary to move in such a way that the master has an exit to the untreated surface. The process takes several days. The glue is applied to the concrete, and then put on the tile. It is necessarily confrontated by China and put seams with crosses. The glue protruding on the junctions is removed until it is frozen. And again we do not forget that even this glue will need waterproofing.

Laying

The decoration of the pool mosaic is preferably performed on the side areas and parts protruding over the water. The technology of its installation is somewhat different from the standard. It is worth noting such features of mosaic as:

- decorative;

- Chips are combined into the matrix;

- requires a small layer of glue;

- It may fit into the sections of any form.

Facing the mosaic of the walls of the pools is performed by separate zones. Think in advance so that one-piece fragments are located on visible sites. The glue is applied to the concrete, and then facing. If the chips are fixed on paper, the laying is made by tiles down the glue. Until its removal, the base plays not only the role of the connector, but also protects the material.

Watching the side and bottom of the pool

Due to what many seams are obtained, there will be a lot of time on their processing. But such auxiliary waterproofing can be an additional decoration.

Shutkish seams

What kind of magazine are professionals? Since this is a kind of waterproofing, you need to select strong water resistant masses. You can take a latex, but an epoxy grout will be preferable for the pool. It contains resins that are hardening after drying and do not let any moisture drops, protecting glue.

Article on the topic: How to choose the best bathroom rug

Folding seams

Grout is waterproofing and decorating method. Use translucent masts with the addition of sequin. Such facing will look spectacular.

The mass laying is made directly into the seams themselves. Try not to stain the tile. To dry out a couple of days. After that, it is necessary to withstand the pool dry by some time until the glue is complete. After 2-3 weeks, boldly pour water and enjoy the result done by the work.