Nowadays, you can create a comfortable environment in the apartment with your own hands without resorting to the services of specialists. Plasterboard allows you to embody any designer ideas and remains easy to work and affordable material. To date, not only interior partitions and ceiling structures, but also bar racks and cabinets are manufactured from drywall.

Since it is easy to make a wardrobe from drywall, and the finished products simply amazing the imagination, then the issue of their manufacturing needs to be considered in more detail.

Plasterboard cabinets with built-in backlight will decorate the interior of any housing.

Cabinet made of drywall

Such a wardrobe will easily fit into any interior and will help solve the eternal challenge of the lack of space. Plasterboard sheets allow you to create products of any forms. In addition, such structures are distinguished by high ecology and do not contain harmful components capable of harming human health.Features of plasterboard

Plasterboard is a layer of plaster, prisonered between two sheets of cardboard. To increase the strength, density and durability of the material, special components are added to the plaster.

The cardboard in this design plays a reinforcing role, speaking the basis for applying such coatings as plaster, wallpaper, paint or tile.

The material is made in a rectangular sheet sheets, the length of which reaches up to 6 m, and the width is up to 1.5 m. The sheet thickness can vary in a rather wide range - from 9 to 26 mm, which allows you to choose the best material, depending on the purpose of the product .

In addition, the sheets of non-standard sizes can be made under the order by the relevant firms.

Sheet of drywall.

As a building material, plasterboard has a number of benefits:

- Not toxic.

- Not radioactive.

- Acceptable price.

- It is characterized by high heat and sound insulation.

- Special composition, which are processed by sheets of this material, prevents the appearance of mold fungi.

- It is processed by any decorative materials.

Article on the topic: Gas column dimensions

Cabinet manufacture

Preparatory Stage and Drawing Development

The cabinet made of plasterboard in the bathroom, living room or kitchen has one principle of manufacture.

Therefore, for any kind of products, step-by-step instructions will be as follows:

- Choose the location of the cabinet.

- Exactly define its parameters, as possible, a detailed drawing of the design. This is one of the most important stages of work, giving an idea of the dimensions of the future product.

- Considering the dimensions, draw the sketch - a schematic drawing of the product.

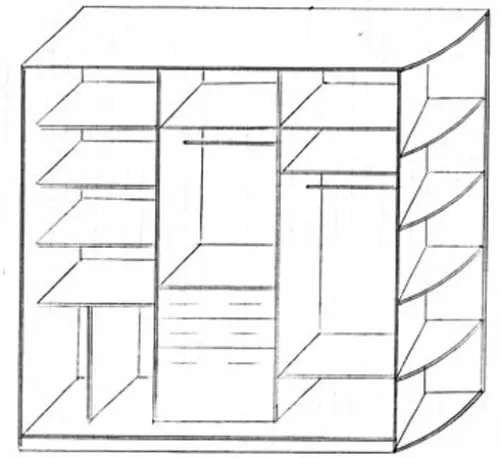

Conceptual drawing of a cabinet made of plasterboard.

By drawing up a drawing, you can use ready-made models from various directories or develop your own option.

The main thing is to take into account all the details: the location of the rod, shape, size and amount of shelves, as well as the distance between them, the presence of lockers and T d.

- Transfer the resulting drawing on the wall to prevent the occurrence of shortcomings in the design. Do not forget also about the thickness of the shelves, which will eliminate all inconsistencies during the installation of the product. When applying horizontal labels, use a construction level, and vertical - plumb.

- Based on the drawing, make a list of product details, as well as accessories. Remember that some details will need in two copies, even though they can be seen in one (roof fixing plates, floor base).

- Prepare the surface to which the cabinet frame will be attached. Drive old wallpapers, if necessary, clean the walls.

Tip!

In order to avoid the transfer of vibrations of the walls and the floor of the cabinet design, it is recommended to pave a special shock-absorbing tape in all places of contact.

Making framework

Consider on the example the manufacture of the cabinet of ordinary parameters. If you wish to make a corner cabinet made of drywall with your own hands, then this instruction can also be taken as a basis, since the angular construction has only minor differences in design.

The formation of the framework of standard, corner and any designer cabinets implies one principle of work.

Article on the topic: Decor do it yourself: Accessories and furniture from rope, rope or jute in the interior (45 photos)

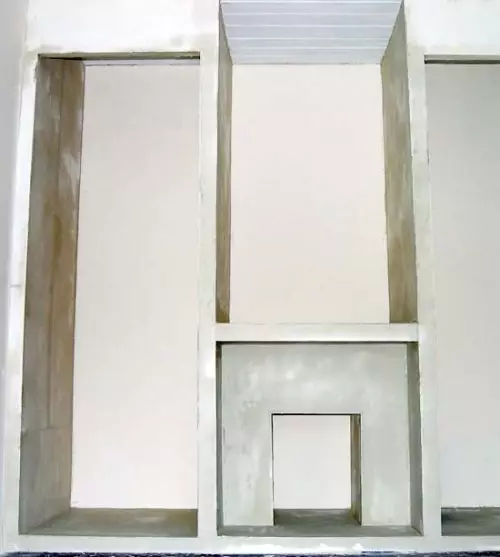

Ready frame for the cabinet.

It is possible to make a carcass for drywall, both wooden rails and metal profiles (in the photo above). Choosing a tree, pay attention to a number of nuances. First, bars should be absolutely dry and high-quality, because the frame is the basis of the future design. Otherwise, the design of the cabinet is deformed with time.

Secondly, the wooden structure is more difficult to collect, it has a greater weight and can take more space.

Metal profiles for drywall are more convenient in operation and get rid of you from a number of trouble. However, they are less durable. Therefore, at this stage, you should decide on what objects you will fill the closet, and how much load will be on the framework.

The construction assembly provides the following steps:

- The framework details are fasten with each other through the outlined lines using self-tapping screws, dowels or screws. We start working from installing guide profiles on the wall, gender and stream. The step between them should be calculated on the basis of the size of the future cabinet. The more dimensions, the smaller the distance for the step should be provided.

- Mount the suspensions based on the cabinet parameters. Strengthen the vertical rack profiles by inserting them into the guide-carbon guide profile.

Frame from guide and vertical rack profiles.

- Additional stiffness of the structure is horizontal elements that act in our case also in the role of shelves and boxes.

Therefore, it is important to consider not only designer preferences, but also use partitions to enhance the design. In places involving high loads, strengthen the frame with the help of transverse regimes.

Installing shelves in the design of the cabinet.

Plasterton covering

The cabinet with its own hands from drywall is a great reason for the embodiment of your designer ideas.

And on how neatly and correctly you will enjoy plasterboard, it will largely depend on the appearance of the final construction.

- We cut the sheets using a hacksaw or an electrolovik.

- With the help of drills and self-tapping screws, secure the sheets of the desired sizes to the frame. Work extremely gently, in order not to damage the material.

Article on the topic: Repair of laminate without disassembly: how to make it yourself

Cabinet design, drywall.

- Be sure to protect the cabinet angles using reinforcing paper, plastering mesh or metal corners.

Corners - the weakest element of the design. It is advisable to make the cabinet cover both outside and from the inside.

Conclusion

Shakes cover with plaster, after which the product is covered with two layers of putty. The first layer should be applied inside the joint using a narrow spatula. Next, we launch the reinforcing tape and apply the second layer.

As a finish coating, you can use paint, wallpaper or special film.

Recommendations how to make a plumbing cabinet made of drywall, provide for the same complex of work, only a tile is used as an finishing coating. More information on this topic you can learn from the video materials provided on our website.