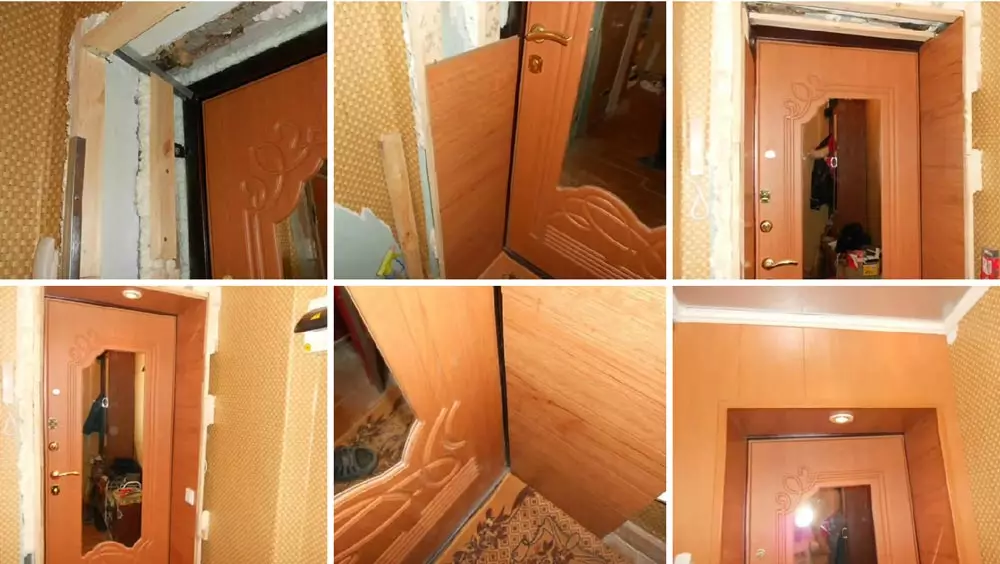

Installation of the entrance doors cannot be considered completely over until the design of the front door inside the apartment will be performed. This is a slope. It is the finishing of slopes that will complete the composition of the input group and beautifully arrange the doorway. Consider materials and technologies allowing you to make slopes on the entrance doors and transform the interior.

Finishing of slopes near the entrance door

Outside the apartment or house after installing the front door, everything is enlarged using platbands or other materials. On the inside, everything is usually much worse - a concrete, brick, fastening elements of the door system come across the eyes. To hide all this, you have to select the materials on your own and finish. The process is simple that does not require special costs of time and financial investments.

The main function of the slope is to give the door to the normal appearance. It allows you to safely secure the door frame, increasing the stability of the design to hacking. That is, the slope is the necessary element, and not just a scenery.

Main ways

The finish is carried out on the basis of the technology of discovery formation - the material for the facing can be chosen diverse. The most important thing to decide which method will be installed.Consider the main technologies, because it is necessary to approach the choice:

- Sealing with the use of solution or plaster.

- Printing finishing materials with solutions.

- Facing facing with finishing materials.

There are other ways, but these are more popular among professional builders and home masters.

Sealing with the use of solution or plaster

One of the acceptable ways to finish the doors is close in solution, but it is necessary to take into account greater difficulty. This approach ensures the maximum level of protection and good sound insulation. The result is a design that will not be fed or have emptiness inside.

This option though has the advantages, it is quite arms in terms of design. Cutting design from the inside is possible with staining or textured plaster.

Gluing finishing materials solutions

If in addition to filling out emptiness with a solution to bind off with different materials, then the appearance of the doorway can be significantly transformed. With a full version, this method combines the advantages of the first option, and the disadvantages inherent in it does not have.

Facing Facing with finishing materials

This finishes implies the installation of finishing materials on a pre-made frame of wood or metal. As a result, the mass of funds is saved, and also the ability to achieve aesthetic appearance. When using a frame structure to obtain high characteristics of the evenness and achieve all levels much easier, which is important.

Where to begin

Regardless of the selected option for finishing the door slopes, first of all, it is necessary to start with the preparatory work:

- The door leaf and the box are protected from damage using painting tape.

- All places are removed (cutting off the mounting foam), which act and can interfere in the installation process.

- The entire working surface is drowning and ground. Experts recommend using deep penetration soils.

- The power cables and wires are carried out, which will serve to illuminate the hallway. If the slope is performed on a frame technology, the installation of the wiring is better to postpone on then.

Article on the topic: Treeship entrance doors: basic views, design features and advantages | +55 photos

Stages of work

You can split the finish of the front door inside the apartment for three stages:- Preparatory processes (above have already been described).

- Installation of discovery with the selected method and material.

- The finishing finish is the last operation and decorative design of the opening.

10 options for finishing internal slopes

Above, we considered the main methods allowing to separate the surplus indoors. Based on their base, another 10 finishing options. They are suitable for a wide range of cases. It should be understood that the ideal version of the finish does not exist - each method has its advantages and disadvantages.

Plasterboard

The finishing of door slopes using drywall is the most time consuming and most favorite method. It is not enough to graze a little drywall, it is also necessary to put a putty on it, and then paint acrylic waterfront paint or crack off the overalls. But as a result, it will be beautiful and the most smooth surface.

Work on the separation finishing can be performed in two ways - frame and frameless. The last option is easier. Adhesive finishes using drywall does not require particularly thorough preparation, it will not be necessary to smooth out the working area. If there is a slight body on the side wall, then it is corrected by applying a thin to 10 mm layer of plaster mortar. If the base area is initially smooth, then the task is simplified as much as possible.

The algorithm will be as follows:

- The base of the opening is diligently ground and wait for complete drying.

- Dimensions measure and apply marks on plasterboard plates.

- The jigsaw cut the sheet into several necessary elements.

- On the workpiece every 15-20 cm applies "moment" and its analogue.

- The glue gives time to dry out - waiting until a characteristic film appears on the surface.

- Apply the parts to the wall, align, pointfully pressed palms.

Instead of glue, liquid nails are also suitable, polyurethane adhesive compositions and mounting foam. But using foam, it is necessary to work carefully - there is a risk that the sheets will shift.

On video: The easiest way to finish the top slop.

Plaster

The use of plaster solutions for finishing door jambs will require the master of certain skills. The work is sufficiently dirty, and also requires a lot of time. The wall should already be aligned during the preparatory stage, purified from construction dust and is projected.

Special attention should be paid to the concrete jumper, which is located above the door - it is treated with "concrete contact". This is a special soil for surfaces that poorly absorb moisture.

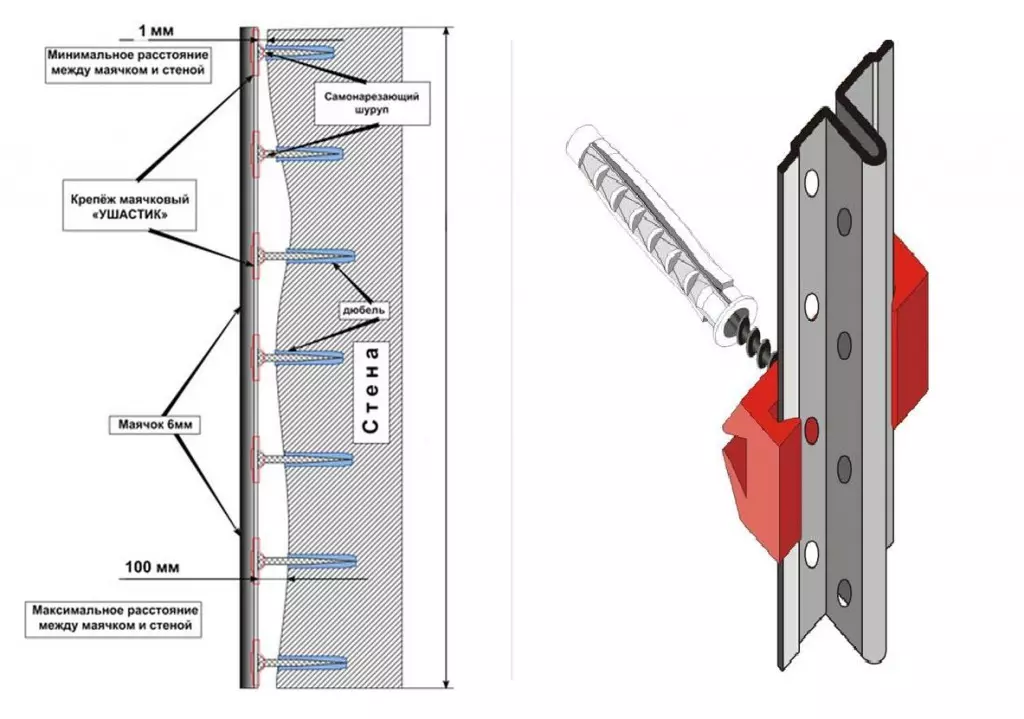

For plastering, accurate installation of beacons for leveling is also necessary. The algorithm looks like this:

- Using the level on one of the side walls at a distance of 3 cm from the door, the position of the vertical line is noted.

- Next, through the line through each 30 cm, the holes are drilled - their diameter should be 6 mm.

- In the resulting holes, the dowel is 6 × 30 mm and the twine align the hats in the level.

- On the clips pinned the beacon and check verticality.

Article on the topic: Calculation of doors for a wardrobe

After setting the beacons, it is processed to prepare a solution. The easiest and most inexpensive option is the use of the career or river sand and cement M-150 or M-200.

To obtain a loyal consistency, the ingredients are mixed in the following sequence:

- Prepared materials are sifted through the sieve - cell is 3 × 3 mm or more.

- In the container mix 3 parts of the sand and 1 part of the cement.

- Stirring, it is necessary to add clean water to the container.

- At the same time, the solution is mixed using a special shock on a drill.

When the mass is enveloping the tool like the dough, the mixture is ready for use. A spatula or celma with a small force, the mass is thrown onto the wall from one and the other side of the jambs. It is necessary to completely close the installed beacon. When a small site is passed, go to the processing of another. Lighthouses are applied by the rule and smooth the layer of the plaster mix. So get a perfectly smooth surface.

On video: Plaster slopes inlet door cement-sandy solution.

Decorative plaster

The technology of finishing the door frames is almost similar to conventional plastering. Apply this mixture is recommended for pre-twisted areas. If a decorative composition is applied with texture, then the draft wall is allowed to be separated not perfect. If separated additionally using color stone crumb, it will turn out a beautiful and durable surface.

Among the disadvantages of this method, it is possible to note the cost of finishing material, high labor intensity and the fact that a lot of dirt in the process.

MDF panels

This is a faster of all types of finishing works. In the process, you will not need a large amount of material and tools. It should be noted the simplicity of installation, but only if the slope is quite narrow. If the slope is wide, then the seams will be noticeable between the panels.

The easiest way to use special ready-made elements for finishing door boxes in the form of the letter G, but the problem is that they are not cheap, and you can not get it everywhere.

Installation is carried out according to an algorithm similar to plasterboard, but may differ slightly. It also uses glue, the wall is pre-processed, and then the elements are glued to the surface. It is necessary to control the position of the vertical elements.

If heavy metal doors are installed, there is a high probability of deformation due to high loads. Therefore, plaster can crack after a year. In such cases, a frame installation is applied.

Such technology is optimal when:

- It is necessary to prevent the deformation of the surface;

- A heavy sheet of MDF is installed;

- It is necessary to eliminate excess space from the inside.

The simplest is the solution using an aluminum profile as a supporting structure. It is allowed to apply a wooden rail. The algorithm looks like this:

- The walls are cleaned and tested on cracks and cracks.

- If necessary, the surface is repaired and treated with antiseptics.

- Next, with the help of the level, an extreme bar is set or a profile and fix the dowel-nail.

- A parallel to the installed element is mounted a second rack and fasten to the overhaul.

- The racks are fixed in parallel to each other around the perimeter in the doorway.

- The design is amplified by jumpers that must be connected to both parts.

- In the case of a frame of a frame, in the meantime, insulating materials are laid, the planks made of MDF and attach them to liquid nails. It is important to achieve minimal slots between the planks.

Article on the topic: Doors and floor color in the interior: Tips for choosing and combination of shades | +65 photo

On the video: Sleep the input door from MDF do it yourself.

Laminate

This is a variety above the considered item. But, unlike MDF, laminate is more suitable for finishing a door portal of any depth, has good external data. The seams between the panels will be practically invisible. It is only necessary to remember that the laminate is inexpensive and it looks, respectively.

Chipboard

According to experts, chipboard is one of the best materials for finishing doors. Among its advantages can be allocated:

- wide color gamut;

- quick installation without seams;

- High characteristics on heat and sound insulation;

- resistance to low temperatures;

- available cost;

- Long exploitation.

Fasteners cut by size elements is carried out on liquid nails. Works are similar to finishing with the use of drywall. Installation requires degreasing shoals. Next glued elements. When glue polymerized, in between the chipboard and the wall are filled with mounting foam. The color of the panels can be different, it is possible to imitate under the tree.

PVC panels

Such a design looks very cheap, but the plastic is inexpensive, rather durable and simple in care, although you will not call it reliable. Also have to take care of insulation. The process of finishing the door frame does not require special skills, can be carried out even beginner masters.

Artificial or natural stone

Inner cladding with natural or artificial stone is, according to designers, last century. And used such solutions due to the tremendous wear resistance of materials and their simple editing. Among the disadvantages - the long process of gluing stone.

Related walls after gluing the stone can only be painted, or coat with decorative varnish.

Tile and Mosaic

By installing a mosaic, you can admire it for a long time - the service life is very high. Tile materials are not afraid of moisture effects, they are difficult to scratch. But it looks like it is all enough. Ceramics is usually used to decorate the walls, when finishing the bathrooms and kitchens.

Paint

Often, inside the entrance doors are separated by staining. This is relevant if the slopes were previously plastered and perfectly aligned. It is best to choose water-free dyes, but acrylic analogues are also suitable. But if there is no possibility to purchase them, then the usual enamel will come down.

Designers recommend choosing paint so as to get into the total color gamut. But color slopes are mainly in white.

Naturally, the surface must be pre-prepared - the slopes are putty, ground, if necessary, align. Then the surface is thoroughly cleaned. For the protection of doors and walls, the passionate film and the greasy tape are used. For applying paints use roller, and for hard-to-reach places and joints - brushes and sponges.

The door finish can be made independently without resorting to the services of specialists. The main thing is to accurately follow the selected algorithm and purchase qualitative materials. And if you have any questions - there are detailed video instructions for this.

Application of LDSP and Laminated Board (2 video)

Different options for decoration of slopes (50 photos)