The stairs are most often elevated from concrete, because this is a material with increased strength and long service life. However, concrete marches have one serious drawback - this is the "coldness" of the material and an unsightly appearance. To enjoy a concrete staircase, a wood finish is often used. This is the most popular solution that it is worth considering in more detail.

Selection of wood breed

There are various wood species that are suitable for processing concrete surfaces: it is oak, larch, and beech. Rare finishing materials can be applied, which are taken from afar. However, within one region, it is better to choose an option that is characterized by an attractive appearance and practicality. This category includes oak - it is suitable for those who are important reliability, strength and durability of the finish.

The cost is the main advantage of larch, since this tree of wood is available to all buyers, regardless of the current financial situation. Compared with oak, larch is cheaper by almost twice. When creating a monolithic design, this is important.

The decoration of larch has other positive parties:

- reliability and strength;

- The material is not afraid of moisture;

- pleasant coniferous aroma;

- Long service life.

Separate the surface of concrete stairs can be both ash. This option will also cost cheaper than oak. The drawing will look natural, and the strength of the boards will be saved for a long time. Any color is available to the buyer: allowed both dark and light shades.

Beech is also a decent applicant for the use of a monolithic staircase. It has a homogeneous, fine-grained structure, and the surface can boast of pleasant light shades. The quality of the material is also at the height, regardless of the cost.

How to avoid mistakes when installing?

Finishing concrete march Even in professionals can cause certain difficulties. Many believe that the fill of the surface of the stairs is the most expensive part. But this is not so, there are many other nuances.Article on the topic: Installation of stairs on cososters: Schemes and calculation [Recommended values]

That's what you need to consider before finishing:

- Wood facing with a tree - a stage that will require the most cash investments.

- The main thing is not to fix the array directly on the steps, otherwise the finish will not be able to hold out long enough.

- Wooden shields must have a thickness of at least 30 mm, savings on this issue leads only to negative consequences.

- When finishing, the edges, sampling of the grooves, grinding the boards, so do not do without the appropriate equipment and skills to work with it.

Consumables

Before facing the tree, it will be necessary to align the surface of the concrete, the pharynki stage must be carried out. This means that you need not only wooden shields themselves, but also plywood sheets. Wooden finish can not be attached directly to concrete.

Primer, glue composition, dowels for mechanical fastening - these materials and fixtures must be in stock. But before finishing work, the surface of the stairs will need to be cleaned of garbage and dirt, otherwise it will not be possible to obtain a sufficiently strong grip with other materials.

By purchasing paints and varnishes, it is not worth saving. It is recommended to buy varieties with very high resistance to moisture. Such formulations are applied to the surface of the finishing of at least three times. At the same time, each layer is applied with a slight break after the previous one will be applied.

Step-by-step instructions for work

Work begins always with preparation. This is required for both work surfaces and tools currently used. You need to collect everything in one place.Preparation of instruments

The list of necessary tools is not so big:

- screwdriver;

- milling machine;

- grinding machine;

- plumbing along with the level;

- hacksaw;

- electrolovik;

- a hammer;

- electric drill.

Technology of work

You can cope with this type of work independently, although you won't call a simple process. All work on the decoration consists of several steps:

1. The surface of the staircase is cleaned of dust and garbage, after which it is ground. For processing, a special composition of deep penetration is used to increase the density of concrete, as well as enhance the adhesive properties of the adhesive composition.

Article on the topic: Chair with transformation in the stairs: types of structures and features of independent manufacture

2. From moisture-proof plywood, a substrate with a thickness of 1-1.5 cm is cut in accordance with the dimensions of the steps. The substrate allows you to achieve the effect of smoothing the surface, as well as absorb moisture from the surface of the concrete.

3. Moisture-resistant mastic or special glue is applied to the steps, the cut elements are tightly applied to the base. After that, additional fixation is used using self-samples and dubiles.

4. Next to the substrate from plywood, liquid nails are applied and a wooden cladding is applied. Work should be started below. From above on stickies, it is advisable to put the load for the reliability of fixation. If you wish, you can bind ends of the stairs.

5. The last stage involves the installation of the fence - balaasine and rail. The connection of the elements to the base is carried out by screws. When the installation will be completed, it will only be left to close the slots and joints by mounting foam or putty.

On the video: a full cycle of work on finishing.

Installing coming and risers

When finishing a staircase with a tree of self-tapping screws, special profiles and moldings become indispensable assistants, then products are attached qualitatively. The main thing is not to forget to do the groove in advance, for which the milling machine is taken. Flush with the lower part is fixed by the risers. In the groove on the back, you need to install the upper edge.Metal corners must be installed on the side of the sticking. Well, if you can additionally isolate steps. Even 3-millimeter polyethylene is quite consolidated for this work in most cases. Such materials create additional sound insulation, allow to protect concrete and wood from negative impacts from the environment. Steps almost won't hear.

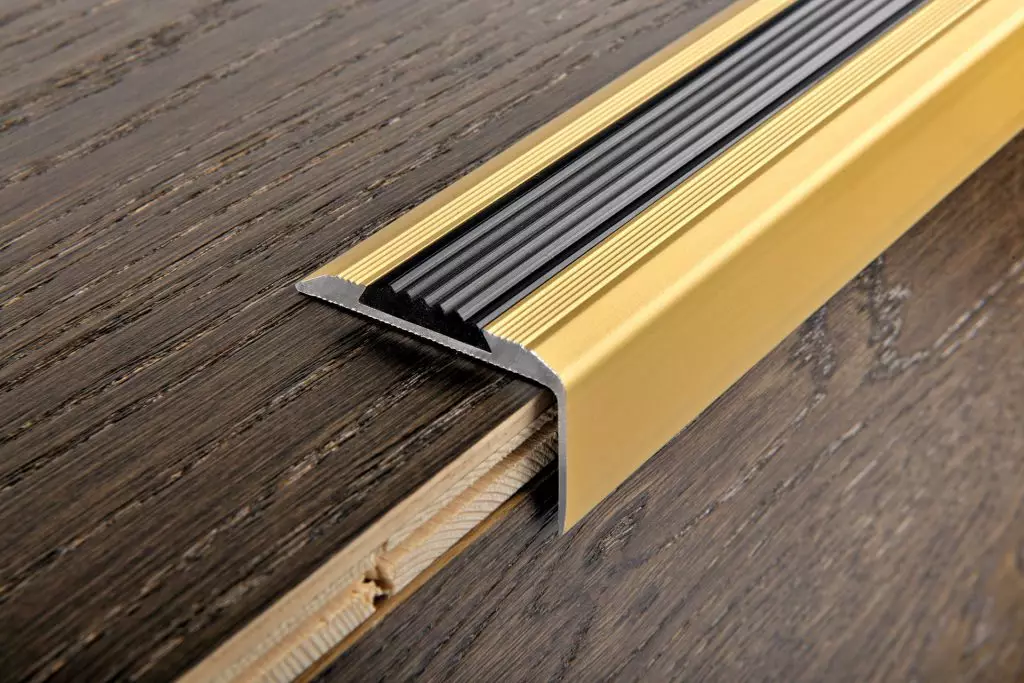

Option number 1 - Using a specialized profile

Special boundary profiles or moldings are often used for work work performed. They are separating different designs. This name is used for an overhead convex plate, decorating the edge angle of steps.

Why do these moldings need? When the owner separates the laminate ladder, the two strips of this material laid on the basis are connected to each other. Because of this, an additional angle appears, capable of spoiling the surface of the outer parts. The cross section of two lamellas is open, it can be observed with a naked eye. The edge profiles are just used to close this joint.

Moldings are superimposed on top of the junction. Fastening with laminate involves the use of glue or self-tapping screws.

Option number 2 - Use of M-shaped thresholds

These elements can also perform the function of edible molding. Such bellows are also called staircase. For the manufacture of M-shaped thresholds, various materials are used: steel, brass, aluminum. Multiple color options are also popular: under gold, bronze, wood.

With metal moldings, not only a decorative function, they help protect the finish from strong wear.

Option number 3 - Quick Step + Incizo

Incizo is a special variety of profiles for concrete stairs, developed by Quick Step. The first product in its own way, which is easily used in one of the four seamless embodiments. The material is suitable for most staircases, regardless of their features.

When processing the staircase, such profiles will not need additional preparatory work. It will be enough for parquet boards to vertical and horizontal elements of steps.

On video: Stair finishing with laminate with Quick Step Incizo profile.

Article on the topic: how to make a staircase from the profile pipe: the choice of design, calculation and assembly | +50 photo

Some of the nuances of the facing

Works on the basis of always begin with the bottom riser. In addition, additional advice must be taken into account.- Do not screw the screws in the base of concrete to the end from the very first steps of work. It is better to wait until the whole staircase is finished.

- The risers need to be installed at the very end. To do this, use boards or special corners.

- Additional details like profiles are required to be installed in the grooves created in advance. The owner himself can control the location of the structure.

- The junctions between coming and the riser first put sand, and then docile with each other. It is important that the shtlankeva has a suitable color.

- The turns are easy to arrange if you cut the source tile material. It is necessary not only to glue the details, but also fix them additionally, with the help of screws with self-draws.

The preparation of the project on the finishing of the concrete ladder is recommended to trust this professional. It becomes important to the correct selection of material, compliance with all rules and requirements for sizes. The main thing is to remember that the formation of cracks is inevitable, even if the accuracy of the documentation is maximum. Splatlevka or mounting foam will easily cope with this problem.

Alternative finish options (2 video)

Examples of finished works (45 photos)