To ensure a full-fledged holiday in a country house or build a bath or sauna in the country. The most important element in the construction of the bath is the floor. The best material for the facilities of the floor in the bath is traditionally considered a tree. This environmentally friendly material is easily processed, has a low thermal conductivity. When heated, the tree emits healthy phytoncides and pleasant fragrance.

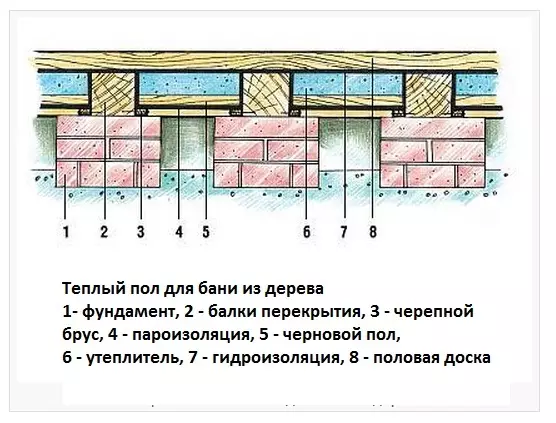

Warm floor diagram in bath.

Sex coverings in the bath are exposed to moisture and large temperature differences. From the quality and competent device of the wooden floor in the bath depends on the service life and the comfort of the bath procedures.

Wooden floors in the bath are 2 species: leaking and solid (not flowing). Sometimes concrete floors with a lattice flooring made of wood.

Stage of preparation

Before the floor device, it is necessary to calculate its area, prepare the necessary tool and material. To create sex you need:

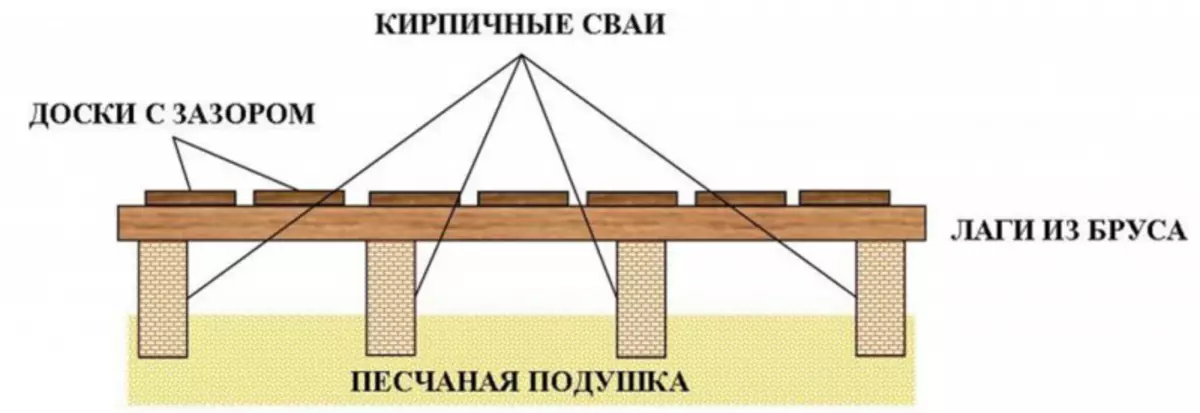

Scheme of the flowing gender in the bath.

- wood hacksaw;

- Plotnitsky ax;

- construction level;

- a hammer;

- galvanized nails;

- Bar 50x150 mm (for lag) or logs with a diameter of at least 15 cm;

- Cutting boards 40x150 mm (for floors)

- Unedged boards for roughing;

- Boards floor tanks (for solid sex);

- Ceramzit;

- Waterproofing film;

- Sewage pipe with a diameter of about 110 mm;

- crushed stone;

- clay;

- Antiseptic solution.

Prepare the required material and tool by selecting the type of floor, proceed to its construction.

Paul leaking

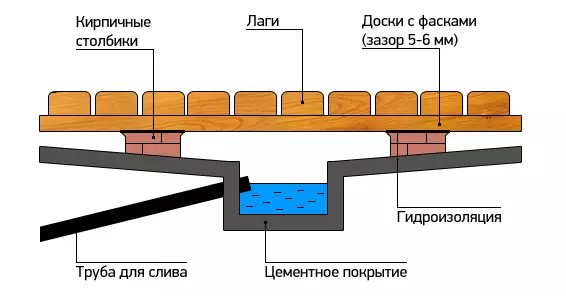

Scheme of flowing floor with drain.

This is the simplest type of floor, water from its surface between the boosters of the boards flows directly into the ground under the bath. The device of this sex costs cheaper and less labor. The main drawback is that its surface is cold. To build such a floor, you need:

- Align and clean the surface of the soil inside the foundation.

- Choose soil to sand, if it is impossible to pour and tumble a layer of sand with a height of about 15 cm.

- Note the location of the installation lag.

- From the brick or concrete solution to establish supports for lags, to the height of the foundation.

- To put on the surface and the loss of a layer of rubble with a thickness of about 10 cm.

- Prepare lags on the width of the floor and put on supports, under the lags to put waterproofing from the frontieroid. In the height of the lags should be at the level of the bedroom crown of the bathhouse. Between the ends of the lag and the wall, it is necessary to leave the ventilation clearance of at least 3 cm. The horizontal installation of the lag is checked by the level.

- In the width of the room, clapped boards for laying on the lags are cut (should not get to the walls of about 2 cm on each side, for ventilating ventilation).

- Prepared boards, galvanized nails, are attached to lags with a gap between their ends about 10 mm (for draining water and ventilation).

- All wood products are pre-impregnated with antiseptic.

Article on the topic: Gas column on liquefied gas

Non-pending wooden floor

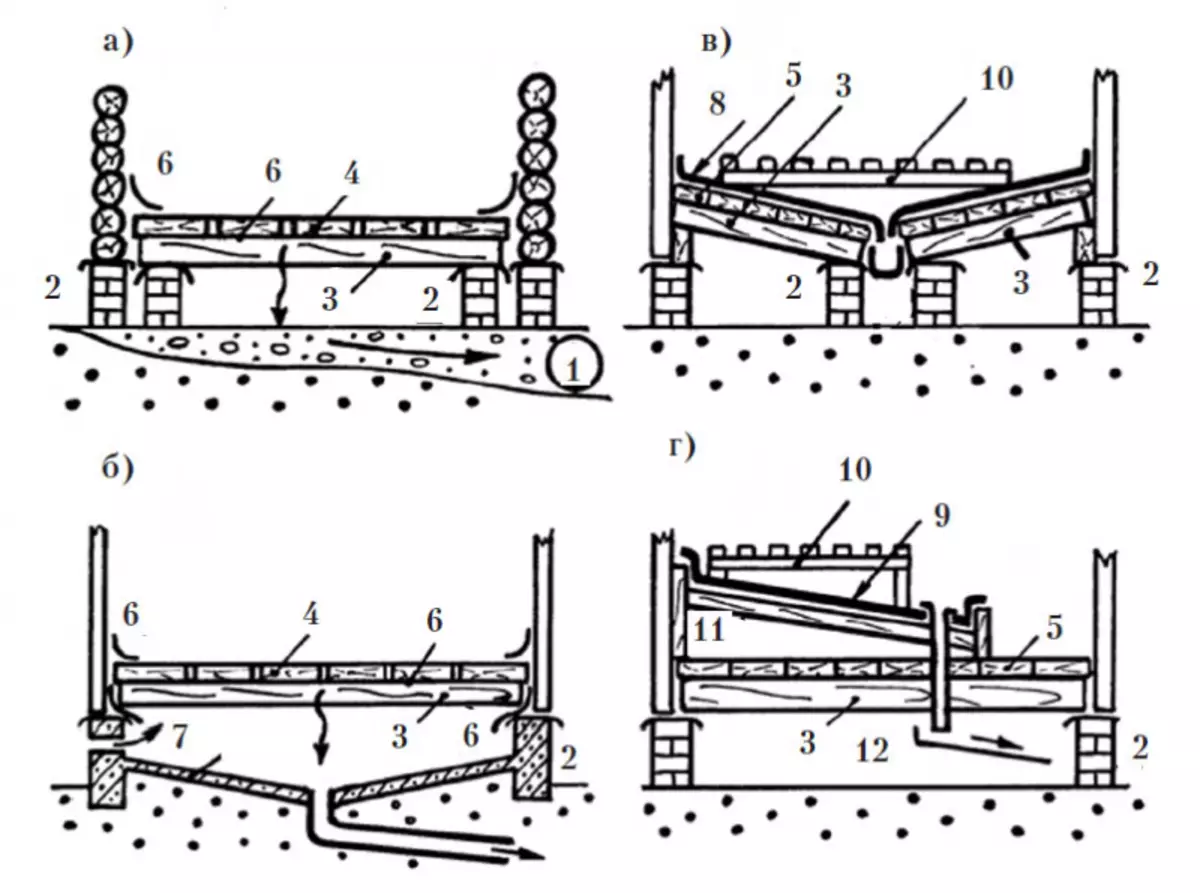

Types of floors in the bath:

A, b - flowing floors, in - non-pending, g - inclined pallet.

1 - filter-trench, 2 - foundation, 3 - lags, covered with Ruderoid, 4 - sex flowing, 5 - solid floor, 6 - waterproofing, 7 - concrete waterborne,

8 - Waterproofing, 9 - stainless steel pallet, 10 - Wooden grid, 11 - wooden frame for pallet, 12 - chute, water water.

Water that fell to the surface of this type of floor, flows into a special hole (ladder) and in the waterborg, and then the tank is output from the bath. Its design provides for a black, insulated floor. The device of solid wooden floor is more complicated and costs more.

The procedure for creating sex in the bath is as follows:

- Inside the foundation is removed by a layer of soil. The layer (approximately 20 cm) of sand is falling asleep and tamped.

- Places the installation sites lag. The support columns under lags are installed (to the height of the foundation of the bath).

- A layer of gravel is stacked on the sand with a thickness of about 10 cm.

- Lags are installed on the supports (there must be slightly above the mortgage crown) with a slope of about 10 ° to the outer wall.

- The basement of the outer wall creates a drain chute made of concrete or from a plastic pipe, cut into half, with a diameter of at least 250 mm. The gutter is installed in a flipper surface.

- A bit of 50x50 mm is nailed to the lower part of the lag (from 2 sides).

- On bars from non-edged board, the draft floor is stacked.

- The surface of the draft floor is closed by a waterproofing film, which is embanked by the insulation (ceramzite), to the height of the lag.

- The surface of the ceramisite is closed by waterproofing material.

- A drainage tube is joined to one edge of the chute, along which water will be outlined outside the bath. The second end of the gutter closes the plate.

- The boards are fitted with a tongue inside the room and are attached (galvanized nails) with a slope in the direction of the receiving gutter. For the organization of info ventilation, there is a gap of about 10 mm from the walls to the end of the boards, water will flock into the gutter and then outward.

- From the 3 sides of the walls, the plinth is installed, closing the gap between the boards and the log wall. The water drain gap is left open.

- All products made of wood before installation are processed by an antiseptic.

Article on the topic: Floor PVC Coating: Expert Tips for Stage

Alternatively, the surface under a solid floor can be concreted, and it is arranged a concrete veil to collect and output water from the bath.

The bath in which the wooden floor device is performed correctly, quickly dries after the bath procedures.

In space under the floor there will be no dampness, mold and unpleasant odor.

Thus, you can make the floor in the bath with your own hands.