The blast furnace is used in metallurgy for the smelting of cast iron and ferroalloys from the charge. It has high performance, so many masters make such ovens for heating a private house lately. These furnaces also have another name - shaft-type furnaces or long-burning furnaces.

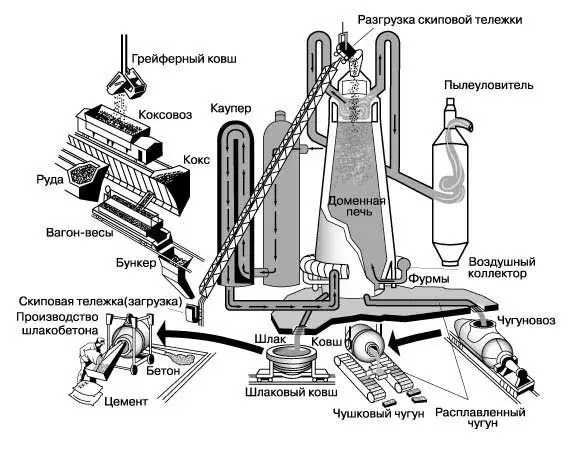

Device of a large blast furnace.

The blast furnace, made by its own hands, works on the same principle as its industrial option, it allows you to use the fuel efficient as possible, and its consumption is significantly reduced. Such a furnace is the best solution for heating at home, cottages, garages, greenhouses.

The main feature that a homemade blast furnace has, is that the process of burning fuel in it is delayed for a long time.

Such a domain made by your own hands can work on coal, firewood and even sawdust. You can buy a durable burning furnace in the store, but if you do everything with your own hands, then the savings will be solid.

Why a homemade blast furnace is so economical

The traditional stove on solid fuel has several drawbacks:- low efficiency;

- Fuel must be laid frequently;

- You can not automate the process.

The homemade domain furnace of all these flaws is devoid, and instead of the process of burning fuel in the furnace, it takes place. Due to this, heat selection is constantly, and on one loading such a furnace can work offline up to 15-20 hours.

Homemade blast furnace

Domain furnace scheme, for its own forces.

If you decide to make such a design with your own hands, then be prepared for the fact that there will be many dirt and noise when performing work, so it is best to perform them on the street.

Article on the topic: Beautiful blinds do it yourself from wallpaper: Step by step photo

The main secret of such a design is the presence of a special air access limiter to corner or firewood. It skips a small amount of oxygen, which is sufficient to maintain the loading of the loaded portion of the fuel, while the active burning does not occur, so the heat is distinguished evenly for a long time.

In order to make this oven yourself, you will need consumables and tools:

- barrel or large pipe;

- Two cuts of pipes;

- channel;

- roulette, level, hammer, hacksaw metal;

- Sheet steel

- welding machine, electrodes;

- Solution and bricks for the foundation.

First you need to cut the top on the barrel, it is necessary to do it carefully, as it will be needed in the future. Instead of barrels, you can use the pipe of the large diameter. To make the bottom for the pipe, it is better to breed a rectangular sheet of metal, it will give it greater stability.

A circle is cut out of the sheet, the diameter of which is slightly smaller than the diameter of the barrel, the hole is made under another pipe. We weld the pipe with a diameter of 10 cm to the steel circle. From the bottom to this circle, the segments of the chapellor are welded, they serve in order to press the fuel as it is extinguished.

For the cover of the barrels take a sheet of metal or sliced earlier and make a hole for the pipe. In order to lay fuel, it is necessary to cut the hatch and install the door. Under it is done the door to remove the balances of the bookmarks.

Foundation and chimney

Since the metal part of the design will be very hot during operation, it is necessary to install the furnace for the foundation. Its weight is small, and the recess for the foundation is not necessary, a simple plate is performed, which can consist of a brick layer coated with a solution.To remove burning products, it is necessary to make chimney. You can take a pipe with a diameter from 15 cm. For its effective work, it is necessary that the direct part be larger than the diameter of the barrel. Better chimney can not bend, and if necessary, the bend angle must be more than 45 degrees.

Article on the topic: Adaptation for sharpening drills with your own hands

As for the reflector, it can be installed or not installed. In the presence of the reflector, such a furnace will work even more efficiently, as it allows redistributing thermal flows.

FEATURES OF MONTAGE

This furnace can be chopped by brick, but if it is in a separate or utility room, then it is not necessary to do it.

- Parts of the chimney must be connected in the direction, inverse the movement of smoke.

- Near the furnace you can not have flammable items, there should be free space around it.

- Chimney must be collapsing so that it can be periodically cleaned.

- To the barrel, you can connect the pipeline in the form of a loop, which will pass liquid into the heating system. In this way, it will be possible to dump not one room, but the whole house.

- To be able to regulate the intensity of heating near the boiler, a crane is mounted, with which it can be limited to a hot liquid stream.

A homemade oven of long burning is an excellent solution for dacha, garage or greenhouse heating, when there are no centralized or gas heating and money to buy expensive equipment.