Video

Outdoor structures

The mounting foam under the influence of sunlight is destroyed, gaps are formed between the frame and walls. As a result, cold air penetrates into the room, drafts are formed. Also, such an external finish performs a decorative function: gives aesthetic appearance. Therefore, the outer elements must be installed either immediately with the window or through a short time.

The external is no less important than internal, and their device and decoration should be approached with no less responsibility.

The outer slopes of the plastic window affect the durability of the structure, its thermal insulation properties.

Plastic windows installer rarely assists on the installation of this element outside. The only exception, if the client immediately ordered the manufacture of not only internal, but also outdoor plastic slopes. At the same time, the cost of the design of windows and work is generally significantly increased. Finishing from other materials manufacturer of plastic windows is no longer performed. Therefore, it will have to be performed either independently or hire a finishing specialist. Of course, the installation process of external elements of windows requires certain skills and skills. Perform yourself of work qualitatively not always succeeded. Therefore, it should be solved, save and do everything yourself or spend a large amount of money, but the work will be performed qualitatively, in full compliance with the manufacturing technology.

Types of exterior decoration

Plaster

For plaster, a special heat-sounding plaster mixture is used - pelite, vermiculite, pearlite-gypsum.

There are several different ways of the device of the outer slopes of the plastic window from various materials. The most popular are slopes from sandwich panels or from plaster. Plaster finish of windows refers to the cheapest mind. Therefore, the advantages of such window elements end, and deficiencies begin. Alone, they are difficult to accurately do, over time they begin to collapse, crack. In addition, plastic windows have a weak adhesion with plaster, which can lead to peeling. As a result, such a window device requires repair from around 2-3 times a year.

Article on the topic: How to update the table with your own hands - instructions with photos of ideas

For shuttering, the following tools will be needed:

- Kelma for applying a solution;

- Malka;

- wooden or metal caulking;

- plumb;

- dishes for the solution;

- urinary brush;

- a hammer;

- foam grater;

- tow;

- Square for measuring the angle of the bevel.

First you need to close the slit to reduce heat loss. To do this, the panel is used, which is clogged with the help of cacopa. For better insulation, the surface can be mixed with a gypsum solution.

With the right approach, you can "kill two hares" - not only to launch, but also insulate the slopes of windows.

Next begins directly itself to shock. In order for the angles to be even, it is necessary to fix on top and on the sides of the plank. For fastening, nails or gypsum glue are used.

When plastering, you need to perform with a small bevel (the angle of dawn of the box), which should be the same everywhere. The accurate calculation is used as a square.

The surface before applying the solution should be cleaned of dirt, moistened with water. And after that, plaster is applied using Kelma. The surface is sprinkled first with the help of low, and then - with the help of a foam rubber. After that, the boards are cleaned, the corners are corrected. On this slopes are ready. To give an additional decorative and protective effect, the surface is treated with paint and varnish material.

Decoration with sandwich panels

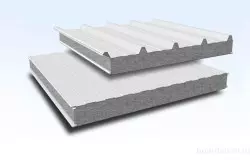

Sandwich panels for finishing external window slopes are two sheets of plastic, between which there is a layer of foamed polyurethane foam.

Sandwich panels for finishing external window slopes are two sheets of plastic, between which there is a layer of foamed polyurethane foam. This method has several advantages: it is easily mounted, durable, resistant to weathering, has high thermal insulation properties, is easily cleared, a wide selection of various colors.

For mounting from sandwich panels, you will need:

- knife for cutting sheets;

- PVC profile P-shaped;

- self-tapping screw;

- Drill or screwdriver;

- Liquid glue.

Installation is as follows. Initially removed dirt and dust. Then the PVC profiles are fixed on the self-tapping screws. They are starting plars in which the panels are fixed. The profile is fastened throughout the perimeter of the window box flush.

Article on the topic: How does the curtain from organza in the interior: let's see

Mineral Wat is currently the most demanded thermal insulation material in the construction market.

Next, the slopes themselves are mounted. To begin with, it is necessary to cut the panels of the required dimensions from a standard sheet of 3000x1500 mm. The first must be fixed the upper slope. One end is fixed in the profile, and the second is held on the surface with a liquid nail. Side panels are also installed similarly.

If necessary, the design can be insulated outside, putting a layer of insulation between the panels. Mineral wool is used most often for this. When installing, it should be noted that the protective film from the panels must be deleted only after the end of the process.

Sheet plastic

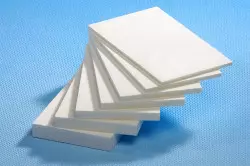

PVC plastics are characterized by excellent moisture resistance, vapor insulation, chemical resistance, and foam plastics additionally have good thermal insulation.

For the manufacture of external window elements, as well as for internal, can be used sheet plastic. Such a finish is durable, resistant to different impacts. Increase thermal insulation properties by laying mineral wool between the wall and plastic. The disadvantages of plastic sheets should include a higher cost compared to many other types of finishes.

For mounting from sheet plastic, the following tools will be needed:

- PVC profile P-shaped;

- plastic profile F-shaped shape;

- Wooden rack with a thickness of 10-15 mm;

- Scissors for metal or knife;

- stapler with brackets;

- Perforator or drill;

- Saws.

The installation of plastic slopes is carried out as follows. First, on the perimeter of slopes on the self-tapping screws, rails are fixed. Fasteners are carried out using a perforator or drill. At the same time, it is necessary to monitor the smooth position of the regulations. Then the starting profile is then fixed along the perimeter frame of the plastic window. They are held, too, with the help of self-tapping screws.

Next, the profile F-shaped is fixed on the brackets. Between two tails must fit the rails. Such a profile is separated by the joint. The next step is to install plastic slopes of the required size. If the design needs to be inspired, then under the sheets should be putting the insulation. Plastic plates are fixed in one end to the P-shaped profile, and the other in the F-shaped profile. On this work end. If you want to give the window a completely perfect look, then the junctions of plastic sheets with profiles can be treated with white silicone.

Article on the topic: Garage from a wooden bar do it yourself from A to Z

Rare types of materials

Outdoor decoration can be performed from cellular plastic. But the material is very fragile, burns out over time in the sun. With a width of more than 25 cm, two separate sheets have to be shy, which spoils the view of the entire structure. Therefore, this material is used extremely rare.

The windows of natural and artificial stone are unusually and originally. Thanks to this material, the design of the window is very beautiful, unusual, gives the whole house a special look. However, perform such a laying is quite difficult, especially yourself. In addition, the stone, especially natural, is much more expensive than other materials.

The choice of material for the manufacture of external discovery depends on the operating conditions, the design of the window itself, as well as personal preferences and the capabilities of the owner.

Load more