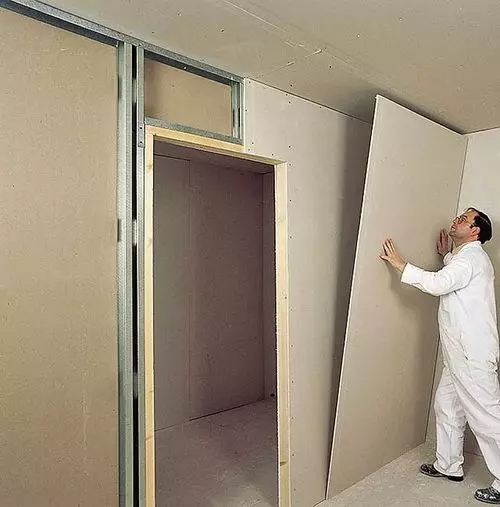

Nowadays, the construction material of plasterboard (or hypocarton sheet, GKC) is located on top of its popularity. Where only this finishing material does not apply: in the construction of partitions, alignment and insulation of walls, installation of multi-level ceilings.

Gypsum Carton Partition Design

This easy to use and cheap material can even be moisture-resistant and used in the bathroom, in the kitchen. Walls from GCL do not need to be smoked, and the doorway can be performed in any form. Only in the plasterboard wall can be made easily arched opening. The doors in the drywall opening are installed very simply, only here you have to choose the design of the door cloth easier. And what if you try to make the door cloth from GLC do it yourself?

If you look at the photo on the Internet, where a variety of plastic facilities are laid out, then any independent structure can be made of drywall, even a wardrobe, just need to comply with all the features of working with this popular material. The process of creating any independent product of drywall consists in the following sequence: creating a frame and a casing with its material.

Choose a place

Before planning the sizes of our door, you need to schedule the doorway.Properly decorated opening of the door - this is a reinforced profile or a used wooden bar, which can enhance the space around the opening, see the photo.

- First, decide on the place where the door design will be located, and install the doorway.

- To create any facility from the plasterboard cloth, the use of metal profiles is considered. Only so you can make a hard frame for any design.

We collect the door leaf from a plasterboard sheet

After we have determined with the size of the design of our door leaf, we select finishing sheets of plasterboard for installation; Ideally suitable material with a thickness of 9.5 and 12.5, it is the most universal and in demand.

Article on the topic: The chicken coop inside: what is needed and how to make

The size of the sheet does not matter, you can use even decent residues for the construction of the structure, the joints are still putting off.

Construction frame base

Usually, a UD profile is used for the base with a size of 50x25 mm, it is non-erased, therefore, the design will be easy.Using a pre-created planning scheme with all calculations, proceed to cutting profiles. An interesting video on this topic can be viewed on the Internet. In the installation of the base cladder, use jumpers on the rack profile, mounted with a screwdriver more often, the design will be tougher. Sometimes in places of fastening the loops on the door, it will be necessary to strengthen the frame base with the help of small wood bars.

Crashing claws

- For the decoration of the frame base, this modern material will require a carpentry knife, hacksaw or an electric bike. With their help we will cut the sheets of plasterboard canvas. If the edges of the product turn out to be uneven can be treated with their edge planer.

- To create an even line, experts use the reposhin. The drywall leaf falls onto the edge of the table, and the line on which the material will be cropped should be abroad. Just hit on the protruding end of the palm, and the sheet will break through the flat line. Paper coating remains unexpected, but it can be cut with scissors.

Sewing sheets will be 25 mm with screws, all operations drill must be performed very carefully, as the fragile material can be damaged.

- An ideal surface can be achieved if you use reinforcing paper, a metal corner or a plaster grid. Sew the door leaf need from two sides.

- All the corners of the future door must be strengthened with a perforated corner, planting it on a gypsum putty. Such a corner is needed to avoid damage when the doors is closed, the surface and get a better and more attractive type of surface. Moreover, it will facilitate our work before final finish. A putty is applied to the angle, the corner is measured and the size is measured.

- We press the corner to the applied putty, and its surplus is removed.

Article on the topic: How to determine and eliminate boiler malfunctions with their own hands

Primer product

- After the perforated corner gets dry, proceed to the finishing finish of the product of the primer surface. Sherry-car mesh is perfect for embedding the joints. Sometimes it is allowed to install in two layers.

- After drying the primer, the surface is sliced.

- Before installing the door, you need to fasten the loops with self-drawing and paint the canvas.

- You can decorate the surface of the drywall with the help of tiles, mosaic, and it is possible to limit ourselves to the painting.

Products from GCL can diversify your interior, today you will not surprise anyone shelves, cabinets, fireplaces from GLC. Products are always light, air, and most importantly - unique.