The relevance of polycarbonate

Currently, so-called polycarbonate windows are used very widely in construction. And it is not surprising. Unlike conventional wooden or plastic, they have a number of advantages that will be described slightly below. For many centuries, the most popular and widespread material for decoration was a tree. He began to apply in the Middle Ages. But scientific and technical progress does not stand still. Today, plastic and polycarbonate windows, canopies are increasingly used.

Today, polycarbonate windows are used for glazing a variety of buildings.

Polycarbonate is a polymer material that is very resistant to various mechanical stress, including shocks, in addition, it is well tolerating temperature fluctuations.

From it make canopies for the balcony. The balcony along with windows is also often repaired, and the canopy is pretty simple. All his physicochemical properties are very valued by workers, and those who use this device. The polycarbonate is designed so that inside the material there are the smallest air pores where the air accumulates, it is it that provides good thermal insulation.

The polycrbonate window consists of a wooden or metal-plastic frame, and polycarbonate inserted into it.

The advantage of it is that it has a small mass, so it is well used for a canopy; He misses the light well, protects against the surplus of ultraviolet and, of course, does not miss the sound. The latter is very important, since the sound is an irritating environmental factor that reduces human ability and worsens his health. The window does not make 100% of this material. It consists of a wooden, metal-plastic frame and a polycarbonate inserted into it. It may be cell or monolithic. Consider in more detail how to insert windows from polycarbonate with your own hands, the necessary equipment and work plan.

Article on the topic: Ideas for a small apartment Studio - which curtains increase space

Necessary equipment

To put polycarbonate windows with your own hands, you need to have a whole set of tools. To do this, you will need:- Lomik;

- nail holder;

- Perforator;

- Passatia;

- screwdriver;

- hacksaw;

- stationery knife;

- building level;

- screwdriver;

- roulette;

- Device for sealing.

You can buy them in any specialized store. Of course, it is necessary to spend some amount of money. To ensure their own security and security of others, you need to protect the territory where the insertion of the windows is carried out with your own hands. Before you begin to work, you need to first buy high-quality windows.

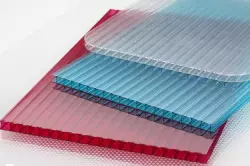

Types of polycarbonate

The polycarbonate is designed so that inside the material there are the smallest air pores where the air accumulates, it is it that provides good thermal insulation.

As mentioned above, the polycarbonate used for windows can be monolithic or cells. Cellular will suit the balcony, canopy. Cellular material has long been used, but he has a number of minuses. For example, for the most part of it are made deaf, that is, only in decorative purposes. It is better to use it for office premises, under the canopy. The monolithic polycarbonate is more durable, easy and safe, it skips the sun's rays well. Accordingly, its value is much higher. The manufacturer has great importance when choosing. It is desirable that she had a great experience and was famous. Before buying the window, it is carefully examined visually, and in the presence of the slightest defects, such a product is better not to buy.

Mounting technique

So, to put windows from polycarbonate with your own hands on the balcony, you must first screw to the frame special details - anchor. This is done with screws. With a side of 2 and 1 from above. Anchor Something resemble a direct suspension. Anchor is attached so that they go inside. After that, the profile is installed on the lower part of the opening. All parts are attached with a dowel, for which the holes with a diameter of about 8 mm are drilled. Next, the frame is placed on the installation profile and wedged with wedges. With the help of the construction level, the frame is seen so that it is strictly in the middle and perpendicular to the edges of the wall. That is, it is leveling in two planes.

Article on the topic: Is it possible to beat the wallpaper on concrete walls?

The frame is then tightly fixed by anchors (metal plates). The next step is to install the windows. In order to set the windows with your own hands, you need to try on the frame. It must smoothly enter the profile. If necessary, it is cut with hacksaw. At the edges of the board put the plugs. Following this, the board is climbing with wedges. Brackets can be applied to make greater rigidity. The latest stage is to check the accuracy of work. Polycarbonate windows are installed shortly, after which the position in various planes is checked again. At the end, the space between the frame and the opening is filled with the mounting foam. So that the windowsill is not extruded by foam, clamps can be applied. In addition to windows, there are canopies from polycarbonate. Sheds for the ceiling are also widely used. This canopy is very durable. If the glass is inserted into the balcony, the technique there is completely different. Canopy can do anyone.