The manufacture of wooden doors requires a careful selection of material. You can independently perform doors from the board, and an array consisting of lamellae is used in production.

Features of the manufacture of wooden doors

Although in modern production there is a trend of the desire for massiness, standardization and cheapening of products, natural materials remain in price. The use of high-quality wood products is a sign of luxury and emphasizes the refined taste of the host. Therefore, the manufacture of wooden doors is a service that is always in price and uses consistently high demand.

To obtain a really high-quality door, you need to carefully prepare a board or a wooden array. Sometimes this process lasts more than a year. Large manufacturers of exclusive products As the first stage of drying, I use a flaccated railway branch, which moves the wagons loaded with sawn timber.

One cycle lasts about a year. During this time, the board gets rid of the uneven moisture content, characteristics within the limits of all volume are aligned. In addition, mechanical stresses are disappeared in the structure of the fibers.

The second stage of preparation lies in the formation of arrays. The board carved from one barrel is selected, the blank is glued and sent to the drying, which can occupy a long time, depending on the gluing technology. In the penultimate stage, the tree necessarily undergoes processing ultraviolet to get rid of moisture on the surface and destruction of bacteria.

The final stage lies in vacuum drying. This ensures the absence of cracks and other troubles. For many months prepared, for many months, the tree is the perfect material, whether it is the production of extra-class doors, furniture frontones or the manufacture of a door-coupe for interroom opening.

General method

There is a standard method of production of doors, which has been used for many years. It is already difficult to determine what was formed earlier - generally accepted features of design or methods of manufacture of the canvas. Methods of work of carpenters for many years have not changed. Manufacturing from the board is the most common way.

Article on the topic: Technology and stages of shocking wallpaper

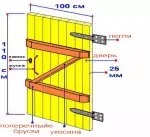

Structurally wooden door, which can be made with your own hands, consists of five groups of main

details.

- horizontal bars;

- vertical bars;

- cross;

- longitudinal racks;

- Pilenki or glass inserts.

With a standard production process, which can be used in the conditions of any workshop, the following procedure occurs:

- Cut bars of the desired size. Most often - with your own hands using a circular saw on the cutting machine.

- Files are formed. To do this, also use a cutting machine, adjusting the height of the table.

- Create grooves for installing parts. Usually used cutters for the manufacture of doors, allowing you to form a cutout, create a chamfer of different configuration, choose a part of the depth of the large area.

- With the help of spike connections and glue parts of the web mounted together. To prevent breaking off site, the connections are strengthened with tongs.

Method of manufacture of canvas

The process of forming the door leaf can provide either a gradual assembly with intermediate fililene installation, or mounting the supporting structure without palemascus. The latest approach is used in the case when the production of glass doors is made. The overall production process can be seen on the video.

The classic way to create the door to everyone is good:

- You can do everything with your own hands.

- It is necessary to minimize the equipment - the machine, hand tools and cutters of several species.

- The assembled door has good strength indicators.

Disadvantages there are also:

- The finished canvas necessarily requires adjustments in the places of thickening connections and joints of individual details.

- In terms of small-scale production or work, it is difficult to choose the board with the same direction of the fibers and the structure.

- Processing accuracy is not enough.

- Create a curvilinear part or a sealer with a complex relief problematic, especially with your own hands, acting by low-power power tools.

As a result, the finished door need to be processed, bring, to grind with your own hands. It will not have a truly exclusive appearance, uniform surface pattern, the perfect joint articulation of the details of the most accurate sizes. Therefore, in the high-quality product segment, a different method of production is used.

Article on the topic: Burlakovin in the modern interior: 50 original photo decoration photos with their own hands

Array as source raw materials

Blooming of browns for the canvas

High-quality door canvas provides not only strength and clear geometric characteristics. Conditions are placed on the absence of bitch and defects of the structure of the tree, as well as on the uniformity of the drawing. Similar characteristics can provide only artificial material - an array of natural wood. It is formed by gluing browns among themselves. Two approaches to creating an array are used:

- The technology of gluing into one layer - the board or bar is located in one direction.

- Several layers of wood are sick. At the same time, the laying is made at an angle of 90 degrees.

This approach is ideal if the manufacture of non-standard doors is required. For the production of a batch of products, the desired set of arrays of the required dimensions is created, which ensures high uniformity of the characteristics of the appearance and physical indicators. In addition, for the formation of the array, the board is selected very carefully. The fiber pattern is joined, plots with knots are rejected with their own hands.

It is possible to use the wood array if the manufacture of glass doors is required. In this case, its size is formed, based on the cutting card. The technology provides for obtaining from one billet of several finished frames that will become beautiful door clides after inserting glass.

The manufacture of the door-compartment also requires the use of the array, since such products are made by the requirements of maximum compliance of the size and minimum levels of deformation in any changes in operating conditions. This feature provides a three-layer glued array. The manufacturing technology is such that it is obtained very durable, almost not prone to deformation and has better characteristics for processing.

The manufacture of wooden doors from the array occurs as follows:

- Created a blank. Its dimensions are clearly calculated, based on the size of the door canvase and the amount of cutting to get parts.

- The array is stacked in the press, undergoing treatment with temperatures, ultraviolet and final

Manufacturing and grinding

Stage of vacuum drying.

- Cropped to the details. It is done on high-precision machines. It is ensured by a minimum of waste.

- Details are milling. Machine equipment is used than accuracy achieved, as well as the ability to create complex champers and curly elements.

- An assembly is made in a steel form. Thus, the size correspondence is achieved within the entire batch of products. The process can be seen on the video.

- The surface of the finished door leaf is grouped.

The final stage is coloring. It passes in several stages, including primer, in chambers, similar to painting boxes in the car service. One of the stages of the process is shown in the video. An acrylic dye is used to prevent cracking. With a light deformation of the door, it can stretch.

Article on the topic: how to choose and apply texture paint for walls