How to make an arbulence. Independent manufacture. Homemade Arbalet

Shooting, as a sport and the possibility of self-realization, has long been successful in humans. The indicator of this is numerous competitions using a variety of weapons. One of the oldest species is a throwing weapon. Increased emotionality of our days finds a response in archery tournaments and crossbow.

Sports shooting from the crossbow in our country is not as developed as a leek shooting. This state of affairs is due not to the lack of interest, but a banal shortage of small-hand inventory. The arbalt sports itself does not doubt a lot of advantages. It is an extensive field for disclosing and applying a certain kind of talents.

As a way out, you can make the crossbow with your own hands. It is not so difficult, as far as it may seem at first glance. Crossing design is simple. In the pool or onion shooting sections there are armory workshops, which is easy to find talented artist masters. Such a specialist can make an arbelt from what has at hand, replacing missing materials on similar. For firing on targets, homemade crossbow is quite suitable.

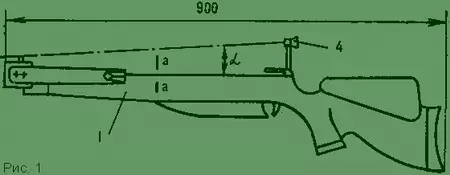

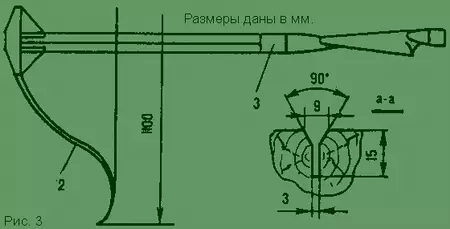

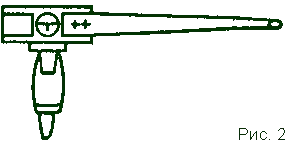

We made a drawing of the crossbow and gathered it with their own hands. When it is designed, the developments of foreign manufacturers and fellow athletes manufacturing crossbows without the help of specialized firms were taken into account. Our cross is different in that as an elastic component we chose the shoulders from the bow. This choice is justified easier, in contrast to metal shoulders, weighing. Plastic shoulders also smooth physical contact from a strong return. To get the opportunity to shoot aiming at a distance of up to 60 meters, it is enough just to pull these shoulders without an application of a special force. The possibility of using the shoulders from broken bows is another positive feature of our device. The main thing to choose a pair of strength. We offer you carefully examine the drawings of the crossbow and start assembling. Crossow make - not the field go. Crossbow device: bed, shoulders, trigger, sighting devices. For the manufacture of beds, natural wood is used, solid or glued, mostly solid rocks. Exemplary sizes can be seen in the figures (1 and 3) - the arbulence drawing. The form of arrows chooses itself, guided by the convenience and ergonomic of the bed, desired by image. When choosing, it is also necessary to take into account the likelihood of proper manufacturing.

Article on the topic: How to connect a three-block light switch

The use of a log from small arms, makes it possible to significantly reduce labor costs for the manufacture of crossbow. The trail from the barrel, remaining in such a bed, must be scored by wooden bars, firmly putting them on epoxy glue.

Separate attention deserves the processing of guide booms and theetics. Their finish significantly affects the accuracy of the hit. The lines of the guides must be immaculately straight and smooth. The preferred option is grinding on the milling machine and the subsequent treatment with a shallow grain. Next should polish the guides. View the size of the groove of the arrow guide, the diameter of which is 8 mm, in Fig. 3. Crosses, with shoulders attached to it, is installed from the end end of the bed. It is usually cast it from aluminum alloy, but the manufacture of aluminum blanks is possible. The tree can also serve as a suitable material.

A window from which the arrow will fly out should be opposite the groove that sends it. It is so the window should be located on the bed of the cross, containing elastic elements. At the same time, during the departure of the string should be pressed to the smooth surface of the bed. The attachment of each shoulder to the cross is occurring with two M8 screws. The principle of triggering the descent mechanism is designed in accordance with the description of the Middle Ages Arbelt Device. Without special problems, it can be made even with an average light level in the workshop.

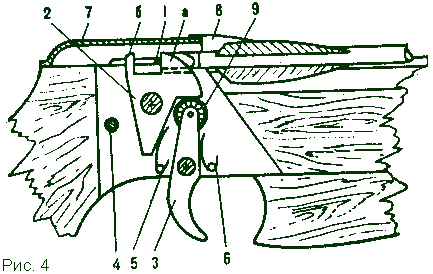

The way it works and how this mechanism works, it becomes clear from Figure 4 - a cross-line scheme.

When the action of 1 crushed, it is adherent with a lever. Limiting the stop 4 occurs in the process of moving the lever. In order to soften the power of the blow to the emphasis, it is necessary to wear a rubber tube on it. The emphasis should be in a position in which the extreme position of the protrusion and the lever is lower than the guide surface of the bed. In this way, the process of slip is warned. After the shot is made, the spring 5 holds the lever in the extreme position.

Article on the topic: Homemade hard floor for an inflatable boat

In the process of pulling the crossbow, the focus is carried out in the protrusion 6, the lever 2 takes its own initial position. Spring 6 acts on the trigger so that it carries out a turn, lever and the strings are fixed. In order for a string not accidentally jumping out from the protrusion A, the descent mechanism closes with a lid 7. The spring 8 of the flat type is attached to this lid, which holds the arrow on the guides at the moment of targeting the sight. Bearing 9, which is attached to the tip of the trigger, sufficiently weakens the power of the descent. The selection of the lowering level is carried out by dummonizing the surface levering on the lever bearing 2. In order to reduce the weight of the lever, it is better to make it from the light alloy D16T. The replacement of springs 5 and 6 can serve as English pins. The descent mechanism can be mounted in a metal housing, after which it is inserted into the socket of the bed and fastened with two screws. Thus, it is possible to significantly increase reliability and simplicity in adjustment. But this method makes the design more complicated, also for its implementation will require metal-cutting machines.

Aimicious proclaiming of the crossbow comes from the whole and fly. Vertical corrections are entirely reinforced on the lid of the snap-in mechanism, and the horizontal - a flour, reinforced on the bracket of the elastic element.

The options for the constructions of these countries may be much, depending on the possibilities of manufacture, the presence of ready-made sights from self-controlled bullet weapons, etc.

It should be borne in mind that the trajectory of the flight of the crossbill is deliberately, so the whole must be achieved significantly above the flies. The angle of exceeding the aiming line (CM. Figure 1 - Crossbow drawings) Covers from being trained, the tension of the tension of the tension, dontails, etc. In our crossbow at a distance of 50 m, it consumes about 6 °.

Convenient constructions of the whole, allowing it for a piece or lacking during transportation.

Article on the topic: Gaming house for children: step-by-step photos, schemes, drawings

Our crossbow, the manufacture of which is described above, is racchitan for the starting line with a diameter of 8 mm and a length of 350 mm. They can be easily made of duraluminum (Slolav D16T) tubes with thickness of the shadow of 0.5 mm. Occuping the tip and plumage as it is done for a log box. It should be borne in mind that a cheapscript starts for a crossbow, unlike onions, should not have a cutout for the taper. It is convenient to pull it out of a tree in the form of a plug and insert the tube on the glue.

In conclusion, he wants to express the hope that you understand how to make a crossbow, its manufacture of cylinders will give you a lot of pleasant, and the lateral of it will give you to accurately have a well-to-reach air. Do not forget only about the fact that the crossbow, like a budding weapon, requires the interpresence of the response relationship and comparison when the creation of the escaped effects. And the amount of pleasure directly depends on how the crossbow is made.