Almost any owner of the apartment wants to equip a small workshop in their home. If there is no garage or another utility structure, then the installation of the workbench on the balcony will be the best solution to this issue.

The workbench is a versatile table equipped with various plumbing, carpentry equipment and tools. How to organize a small workshop on your own glazed balcony? We will tell about this in a popular form in this article.

Desktop dimensions

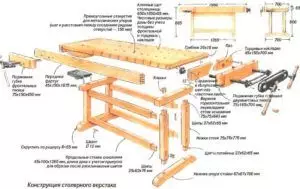

Workbench design

To understand what sizes should be the workbench, measurement of the balcony. Based on the data obtained, the design of technical furniture is projected.

The main size is the width of the table. Typically, the workshop is placed in one of the side sides of the balcony or loggia. The distance between the front wall of the house and the frontal fencing of the balcony or loggia and there will be a width of the table. The height of the table depends on the individual physical data data. The standard height of this type of furniture is 750 mm. The depth of the table top can be any user friendly.

Be sure to be needed for the feet of the employee at the table. In the absence of such a workbench, it will be very uncomfortable, especially with a long stay of a person behind him.

Types of workshops

Before starting to equip the mini workshop on the balcony, it is necessary to decide for what types of work work furniture is intended. The working table can be plumbing, carpentry and combined.

Flooring table

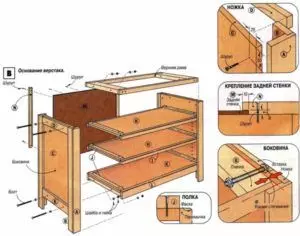

The locksmith vestock must withstand the load from heavy metal processing work. Therefore, the framework of the table is made of metal profile and sheet.

Support racks are made of metal profile. Strong racks can be made from the corners with the width of the shelf 35 mm, cooked into boxed supports.

Horizontal connections guide for drawers are made from 20-corners or other suitable profile.

Article on the topic: Laying of laminate in the doorway: Step by step instructions

The countertop is cut out of a metal sheet with a thickness of 8 mm to 10 mm. You can use a metal sheet of greater thickness. As practice shows, the use of a sheet with a thickness of more than 10 mm. Nothing other than a significant increase in the table will not give. And this is important for the carrier ability of the balcony plate, especially with shock loads from fitter work. About how to make workshop with your own hands, look in this video:

Boards Countertops Treat Antiseptic and Fire Resistant

To mitigate the shock loads form a wooden base for a metal sheet of tabletop. For this, wooden boards with a thickness of 20 mm are placed in a welded frame from the 22nd corner. Metal sheet weld top to the frame.

Dry boards must be treated with an antiseptic and fire-resistant drug.

The "wooden lining" under the metal countertop will soften the blows with a hammer and drown out other sharp sounds when processing metal parts.

Features of the device

Workbench design

For fitter work requires vice. To secure them on the workbench, the stakes of a certain width are needed. When placing a working table in the end of a balcony or loggia between the side walls of the balcony, a vice can be fixed only on the front of the table. Such a position of vice can cause inconvenience to perform fitter work.

Alternative

If the balcony is allowed to think about the manufacture of the workbench r - shaped in the plan, where one part of the table will be in the end of the room, and the second part of the vestigur will be under the balcony window.

Welding work on the balcony and especially in the residential room is extremely unreasonable and dangerous. Therefore, the workbench is manufactured in specialized workshops that have admission to the production of welding.

It is necessary to know that delivery and installation on a balcony of a all-welded design can create certain difficulties. G - a shaped all-welded workbench can be made of two sections connected by bolts.

Article on the topic: Sharpen chainsaw chains do it yourself. Sharpening tool

There are options for prefabricated workbenks. Table parts are collected entirely on bolted connections. Such designs are mobile, do not cause difficulties when transporting them. The disadvantage of such structures is the constant weakening of bolted connections under the influence of workload variables. Therefore, the mounts need to be constantly checking and tightening.

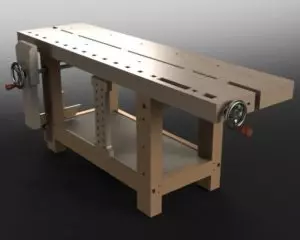

Joiner's table

Joinery table

The joinery workbench can be made from the old written table. If there is experience with carpentry tools, then you can make the work desk independently from wooden materials. On the Internet there are a lot of drawings for the manufacture of joinery furniture.

Combined workbench

The combined design is based on a tabletop made of one wooden half and a different part coated with a metal sheet. Thanks to such a structure, the workbench on the balcony allows you to engage both fitter work and carpentry tree processing.Finished products and accessories

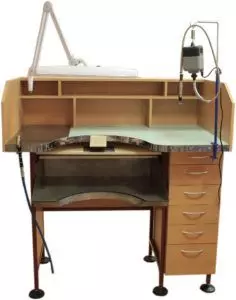

In construction hypermarkets, you can choose a ready-made desktop of the desired size under the dimensions of the balcony or loggia. This will free from problems searching for materials and manufacturing work furniture. About the manufacture of workbench on the balcony View in this video:

Along with the workshop, you need to purchase table lighting devices, vertical wall-mounted fixtures for placing frequently used tools: screwdrivers, chisels, pliers, etc.