Ozonizer with his own hands

We get ozone or chemical synthesis on the table

To solve some tasks, ozone is needed. Whether it is a chemical reaction or disinfection of the room - it will still have to receive on the spot, as it is miselets. Read more about Ozone can be read in Wikipedia.

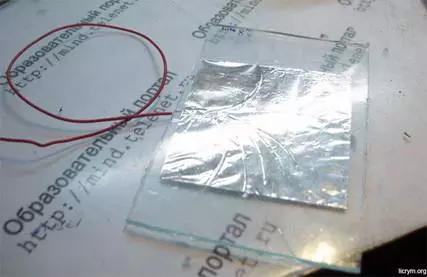

To get ozone, we will be one of the most affordable ways - with the help of a quiet electric discharge (on the Internet, it is very often erroneously written - "when the air is transmitted through the air"). To do this, we need a high-voltage generator, compressor, 12 volt power supply and what's in the photo:

Take three-minute meter glass (the thickness is selected empirically for this generator, if the glass is thicker - the discharge will not be, if it is thinner - it will lead it). One of the electrodes will be a canning bank, the edge of which will be removed from glass by 0.5 mm, in this gap will be discharged, and through this gap we will pump air. The second electrode will be glued on the back of the glass aluminum foil:

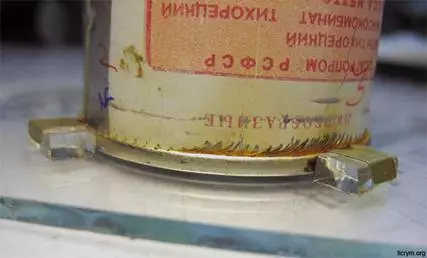

In order to maintain the specified gap, we solder 4 corners to the bank, and thereof it on the glass supports:

Please note that all sharp edges must be rounded so that there is no parasitic corona discharge. Design assembly:

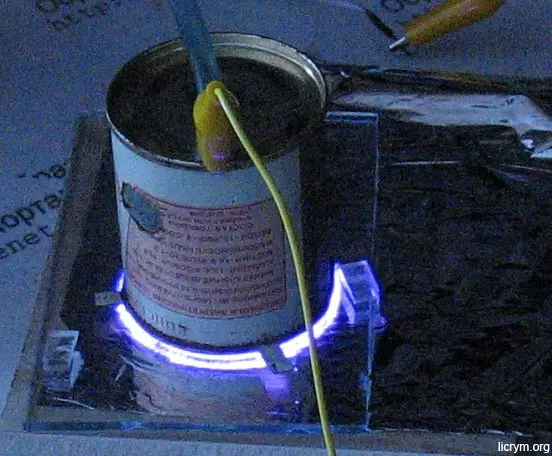

It is very important to calibrate the gap, so that the discharge happened evenly throughout the circumference, otherwise the effectiveness of the chamber will be small. In order to check the calibration to start the discharge to be frightened, i.e. without air pumping:

(Due to the feature of the shooting and structure of the matrix, the photo is distorted, the glow is actually purple and 10 times less intense. The distortions were made for maximum clarity of the process) The discharge flows with the hissing and appearance of the characteristic odor of ozone. By changing the height of the attack, we achieve a uniform discharge. When the discharge passes with the same intensity along the entire length of the circle of the electrode - proceed to the next operation.

Article on the topic: Metal blinds on the windows: What better?

In the bottom of the bank drills a hole on the diameter of the hose. In the center we solder the spring (and guide if necessary) to ensure that the jackets are pressed to the glass and eliminate the hauling. Finished bank electrode:

We drill holes for the exit of hoses and wires, and defathery glass and the surface of the external case. In this case, container from cotton sticks as an external body. Bill the container with a tap and sealed with silicone.

A day later, the camera is ready:

And here we summed up the materials - it turned out that silicone is not suitable for sealing the input and output of the hose by virtue of weak adhesion with the surface of the outer case. The situation was corrected by glue GUN glue, which turned out to be more hard:

All, the heart of the installation is ready. We collect the installation for ozoning water:

All blocks can be arranged in a separate device and put some entertaining experiments)

Ozone is highly toxic gas, so working in ventilated premises, not allow a long exposure to the gas to the respiratory path to happily ozone smell already at 1/10 of the MPC.

Approximately the ozone per hour is completely decomposed at room temperature. To determine the ozone there is a high-quality reaction - the paper impregnated with iodide potassium and starch in the ozone atmosphere shines.

It is worth noting that the quiet discharge should not move in the arc. The fact is that in the air, in addition to oxygen, there is even more nitrogen, and it is not very good if we have nitrogen connections instead of ozone.