Construction technologies are constantly developing. A few years ago, a brick was very popular. In our time, its main competitor is slagoblock. How to build a garage from the slag block? How much material is needed for this? You will receive answers to these questions by reading the record to the end.

Dignity of material

The slag block is called a block of concrete, which consists of slag. There are many types of slags, but a domain is used for building materials. It is characterized by very high construction qualities. Also, such blocks use inexpensive fillers, by the type of seven or brick combat. The heat transfer of the slag blocks can be enhanced by polystyrene.It is an excellent material for dachnings and buildings of country houses. Blocks have a lot of advantages, and they can even make them independently. The masonry can also be made easily on their own, even a newcomer. The construction of a garage from the slagoblock with their own hands allows to save significantly, delivers pleasure and relieve the mass of trouble. By reducing the number of builders and machines, thereby appearing the ability to reduce costs, and independent buildings is another reason to be proud of its work.

It is possible to build a garage from the slagoblock on your own, and the thermal insulation properties of the material can significantly improve the quality of the construction. Where are the slag blocks? Most often, garages, fences and houses are built. Some features of the material make it possible to determine exactly for what type of building can be suitable. There are two types of slag block - hollow and full-length. Walls are built from the hollow material. Full-scale blocks are more durable, and they are used to build a foundation.

The block does not like to glow, it must be taken into account when building a slag block foundation. Such a foundation can be built only on dry soil or for a small house, building. Construction of a garage from a slagoblock can help save time and money. It is not always necessary to hire professionals for work, because most of the work can be made on their own. Although there is an opinion that slag blocks are not too reliable, in fact, their life is 50 years.

Preparatory work and foundation

Before starting the construction of the garage, it is necessary to do some preparatory work. What is needed for a garage from the slag block with their own hands for a long time and was reliably protected from changes in soil and unstable weather conditions? The first is to conduct a geodesic assessment of the area.

Compared to the distance to the locations of water, communications, the other necessary for the house of buildings, sewage, including.

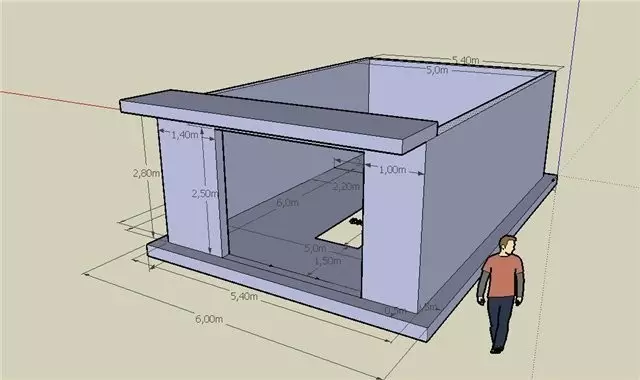

If you decide to build a garage from a slagoblock, the project for its construction should be prepared in advance, as the project is the basis of all work.

The novice builder may be afraid of such a prospect, because many of them believe that the creation of a project is a very difficult job that requires a lot of time.

In fact, draw a draft garage from the slag block on one sheet of paper. Such a drawing is able to significantly simplify work. Calculated on the distance calculator and the amount of materials are able to significantly simplify your work. Also before the start of the construction, it is worth decreasing for yourself how the garage room will be used - whether it will be stored only a car, or there will be possible to repair, storing products and things, can be done under the garage of the cellar. Deciding this question, you can reduce the space for the required homework, having prepared a garage to them in advance.

Article on the topic: Polystrax density and its technical specifications

Construction unit

The foundation for the garage from the slag block should not be very solid and serious, because the weight itself and the design of such blocks is not too large. Therefore, the basis depends on many factors. Among them are the depth of the bookmark, which depends on the drainage of the soil. The presence of underground groundwater can be very important, the direction of their passage, the type of soil - sand, clay, rocks. Deciding with these factors, learning which ones most of them are for the construction of high-quality and reliable foundation, you can start work, but even for the construction there are several ways, each of which is distinguished by its level of convenience.

First of all, the first top layer of the soil is removed. The trench turns on. The trench is filled with sand, stones or broken bricks in several rows. Each layer is impregnated with cement mortar. What is it for? Such a bundle is able to protect the foundation from the destruction that may be caused by groundwater. Digging of trenches in 40 centimeters width and 50 centimeters depth. The bottom is covered with sand, poured with water and should be tamped. This approach makes the foundation durable and strong.

Also, the bottom is strengthened by fittings, they fall so that their location directions were different. Such foundation is concreted and withstands for thirty days. The last method is the easiest. It is called boot concrete. There is a trench, which put the stratum strata. Further, the trench is flooded with cement. It is important to know that the quality of the cement for the garage should not cross the line 150 of the brand. The cement is stirred with sand, 1 part of cement by 2.5 parts of sand. Water is added before the advent of the movable mixture. In order for the newly built foundation to be highly waterproofed, it is steel to rubberoid. It is necessary to do this for several centimeters wider than the construction area. The gate is installed on the strut.

Walling

In order to build walls, not necessarily use special rules. Brickwork can be carried out in several ways - in the floor of the stone, in one stone, in one and a half or two. The strength of the wall depends on this. The wall is also able to withstand the winds of the wind, the temperature differences are high and low. One of the most common ways to build the walls is called "brick". The last row falls and breaks the seams of the previous one.

First, the angles are set, and after the blinking laying of slag blocks continues. The laying during the construction of the garage from the slag blocks is not much different from the laying of bricks. First, the angles are set, they must be vertices of the right rectangle. Between them stretches the lace or rope, which will control the level of masonry, both horizontal and vertical. If you use modern materials for masonry, then your garage will be great. It will also be different in durability, quality and safety. And also blocks from slag is much more economical than ordinary bricks.

Article on the topic: We select curtains for arched windows: photo ideas

Floor screed

The floor is built at the base level, the work process includes surface preparation. The screed should be a decheatimeter. The surface for laying the floor must be prepared - remove the garbage, align the surface, coat with the bottom of sand or rubble as needed. Several types of construction concrete are isolated, and from all their preference to build floor is given to the ready M200.

I recommend a mixture for a tie of the floor, and when the surface becomes strong enough, it will be possible to start it. By installing the floor at the base level, it is necessary to pay attention to its strength. After all, there will be not only people in the garage, but also a car. That is why concrete will perform material for the floor. Its thickness from eight to ten centimeters. Before starting laying, the Earth is aligned and cleaned.

The subftip is carried out by sand or small rubble, after which the coating is taught. The surface of the surface is checked with laces. You can also use beacons from the pipe. By installing concrete portions, it is done continuously, and even between beacons. The installed concrete is maintained, and so that dust appeared on it over time, it is possible to carry out an iron process. There are several ways to this procedure, and each of them is aimed at improving the strength of the concrete coating, giving it an aesthetically acceptable type and removal of ubiquitous dust.

Roof and gate

The roof construction includes preparations for work, and the preparation of foreign beams, which must be longer than the width of the garage by 25 cm. The laying is made across, with increments of 80 centimeters. Brussia is sewn roofing, the thickness of them should be 40 mm, and they fall close to each other close. Then there is a queue of roofing materials that must be laid one by one in a certain order. Keramzit, slag and semi-rigid stove falls on the screed in 20 centimeters thick. The roof is covered with aquaizole and a ruble.

Building overlap can cost quite inexpensive. Metal beams and a boardwalk also play a significant role in this matter. By installing the overlap on the walls, it must be sewn. At this stage, slag warming is carried out, the cost of which is small.

The roof should act as in front and rear. It will protect the walls of water.

The length of such visors can be forty centimeters. On the layer of the insulation slag, which was covered on top of the runneroid, is made cement screed. It is very important to fulfill it as much as possible. Such a roof will not absorb moisture, leak, but for this you need to cover it with waterproof properties. Any types of rubberoid can help perform the roof of their functions most practical. It is glued to the rubberoid melting or mastic, and before the processing of the cement screed is treated with bitumen primer, or "primer".

Article on the topic: Arrangement around the tree: flowerbed, bench, table and even gazebo

Network engineering

Those motorists who have had not very often encountered with the inner trim of the garage, believe that such a finish is needed only in order for the premises to be more spacious, cozy or bright. However, in fact, the interior decoration is also very practical. Building materials that are used by experienced builders can absorb dirt and odors. They are also not affected by chemistry, moisture, temperature, do not burn. There are many internal finishing methods, but at this stage it is also worth thinking about how engineering networks will be conducted in the room.

Such networks are a combination of equipment and communications that will provide garage with warmth, connection, electricity and even sewage. It is the leading fragment of networks that the sewage is considered. It is convenient to use for it to connect to a centralized system. If this is not possible, a well, or well be used. Lighting and power supply is very important - no garage can not be submitted without light and electricity. Wiring should be planned in advance, after it is installed, you can start the finish, without fearing for the fact that you missed or forgotten something.

Heating and ventilation are very important - they guarantee comfort and convenience of accommodation, both in the house and in the garage. The most convenient can be a natural ventilation system. Simple engineering networks can be carried out. However, if the work turns out to be too complicated, the source for the wiring is confused or far, as well as for sewage - construction, plan-project, calculations and work on this issue can be left to specialists, engineers and professionals.

Finish

The finish most often serves as the final stage of construction work. The trim of the garage from the slag block does not require special skills, skills or type of action in order to make a good and beautifully looking trim. The lining and decoration of the walls, both inside and outside the room, can be different. If there is a desire, the walls can be plastered, whitewashed, wipe the cement or covered with clapboard. The room is insulated with fiberglass or foam.

From moisture, your garage can be protected by a film or other way - for this you can make a stripe from drywall. The construction of a garage from the slagoblock can be called a very good idea, such a construction is not inferior to the brick garage released from fashion. The material is also quite acceptable and withstands high loads. The quality of the blocks allows you to use the garage for a long time. The whole design is distinguished by durability and security. If you correctly pick up the color gamut, choose the material and install it, then the internal and external decoration of the room can make your garage comfortable, cozy and beautiful.

Video "What is a slag block"

On the record a man talks about the pros and cons of this building material.