Photo

The greenhouse can be made from various materials in the country. The choice will depend on the personal preferences of the site of the site and the number of free cash. With the help of a tree, you can make a similar design quickly and without large financial costs.

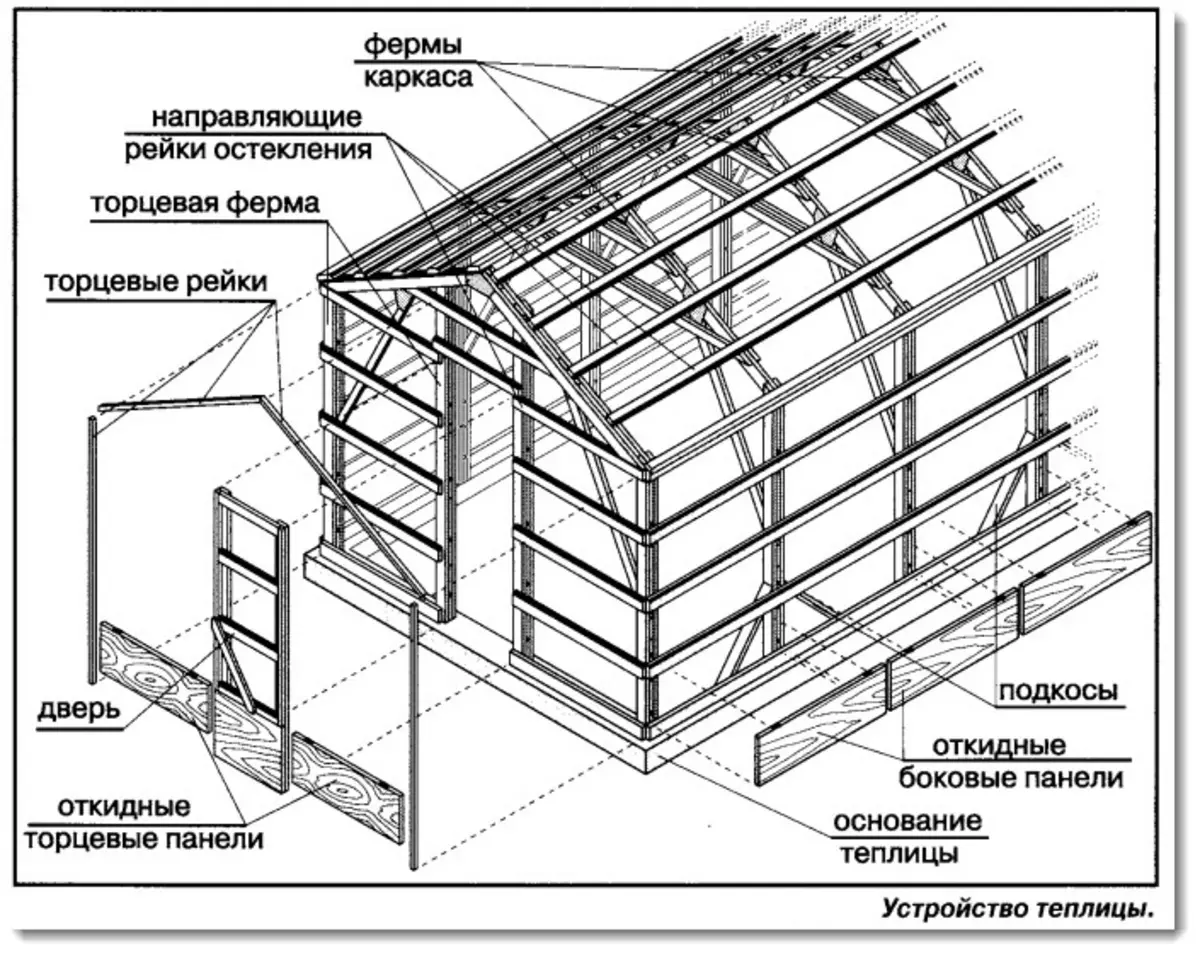

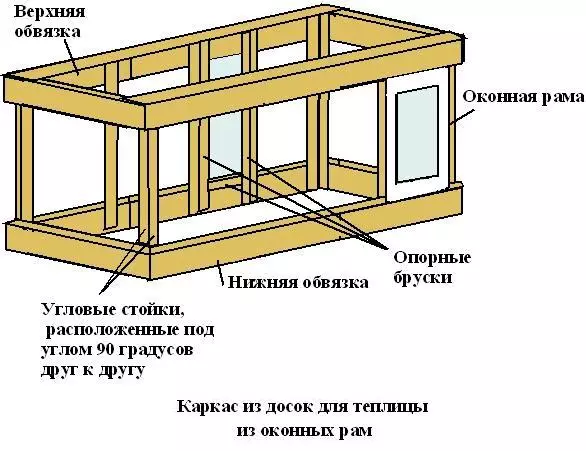

Device greenhouse.

Wooden bar is a reliable material that can be purchased almost in any large construction supermarket. For durability, the bars are slightly different from the metal, but if they are handled by a special impregnation, it will turn out to be extended the possible period of their service. Wooden greenhouses can serve about 5-7 years, and in some cases even longer. Everything will depend on the climate of the area where the design is installed.

For the construction of the greenhouse, it is not necessary to acquire the tree of expensive rocks, as it will serve not much longer. It is recommended to choose industrial trees. In the process of choice, attention should be paid to the quality of the material, technical parameters and the number of defects. For the manufacture of greenhouses, it is best to use a bar without bitch that carefully succeeded.

Foundation for wooden greenhouse

The base for the greenhouse should be reliable and stable. It is best to make a ribbon or brick foundation. Such structures have all the properties that are needed for greenhouses. In addition, such foundations will not be too expensive.

It is preferable to stop your choice on a ribbon base. You will need to perform the following steps:

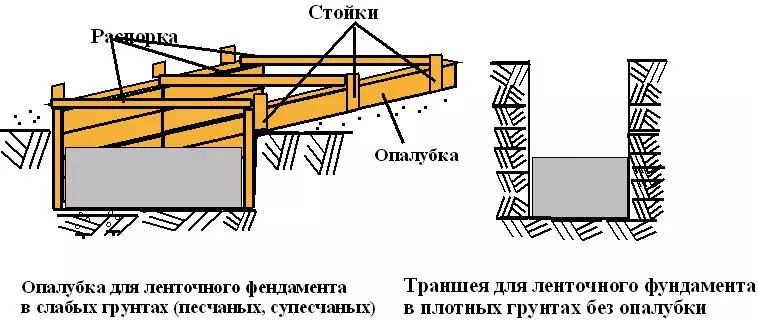

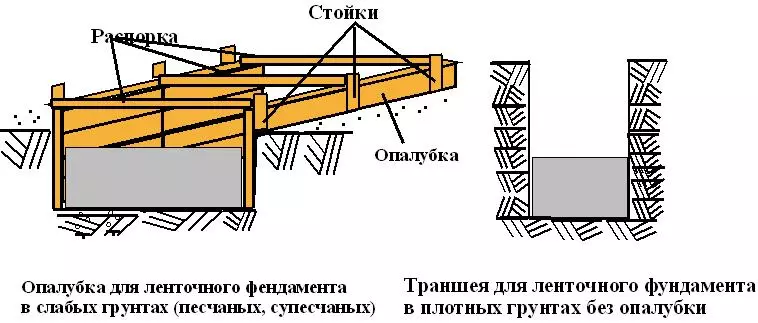

Foundation formwork diagram for wooden greenhouses from window frames.

- First of all, it is necessary to pour the base with a depth of approximately 50-60 cm and a height of 20-30 cm above the ground level.

- The design will need to be reinforced to make it durable and eliminate the sediment in the future. This reason can be used for greenhouse from any material, because in the future there will be a desire to change the framework, then there will be no problems with this.

- After that, the foundation on the tape will need to be hydroizing to protect it from moisture for a long time and extend the overall service period.

The width and form of construction will depend on the size of the greenhouse and the load of the frame, therefore it will not work accurate calculations.

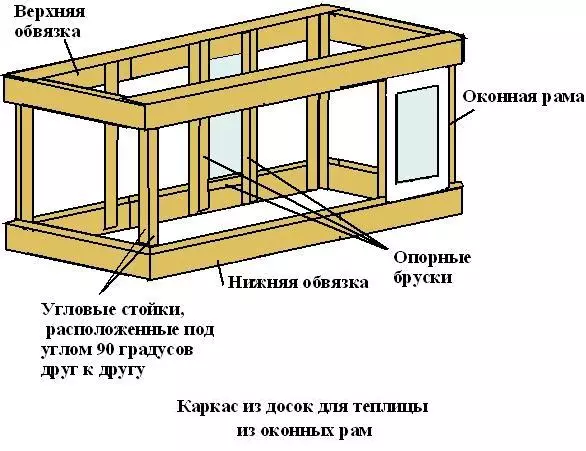

How to install a carcass for the greenhouse with your own hands?

With wood, it is much easier to work than with other materials. Therefore, with the installation of the frame there will be no problems. First of all, it will be needed to fix on the base of the bar, which will be a little wider than the RESEKs used to build the frame.

In order to secure the framework of the frame, you can use a metal corner, which will need to be installed in advance in the foundation. In this case, you can apply fittings, bolts or anchors. It will take it before the mounting bearing of the rail, it will be necessary to handle protective means - antiseptics, olifa and paint. This is done in order to provide a long period of the base of the bottom of the greenhouse design.

Article on the topic: How to quickly and quickly make a chaise lounge with your own hands?

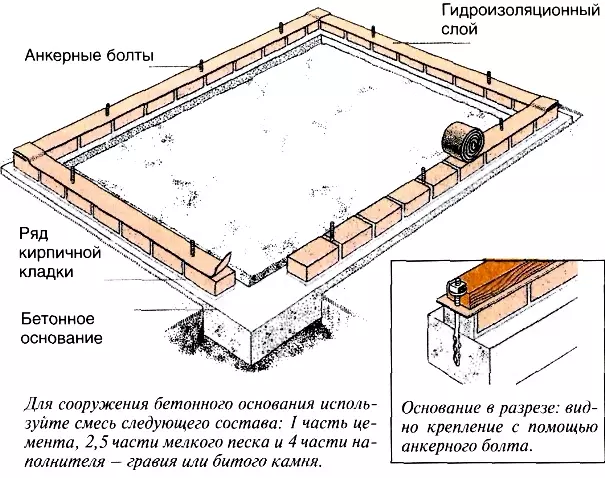

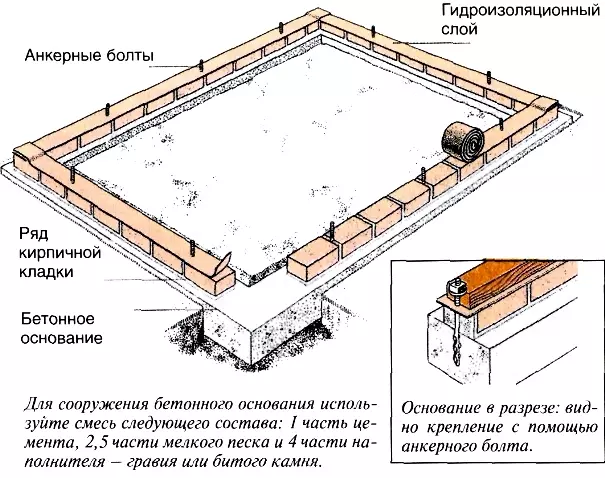

Scheme of monolithic foundation with drainage for greenhouse with their own hands.

When the carrier rail will be ready for installation, the final measurements should be carried out and proceed to work. To secure the basis of the greenhouse design and produce other works, you will need to use such items:

- electric drill;

- fasteners;

- a hammer;

- Bulgarian.

The basis of the structure is attached around the perimeter of the foundation. It is necessary to check that the base is solid, and its parties were connected to each other. The simplicity of the process of mounting the frame of the greenhouse construction and its stability will depend on these values.

Next is the framework of the frame. It is simple enough to install it, since the base has already been mounted on the foundation and is firmly fixed. It will remain only to perform measurements and perform installation, using the schemes. The scheme itself can be seen in Fig. one.

All other elements of wooden greenhouses, frames and vents, the lags of the ceiling are fixed with the help of self-tapping screws, clamps, corners and profiles of metal.

Production of greenhouses of various designs

Before starting the construction of the greenhouse, you should purchase all the necessary items.Standard greenhouse made of small-sized wood

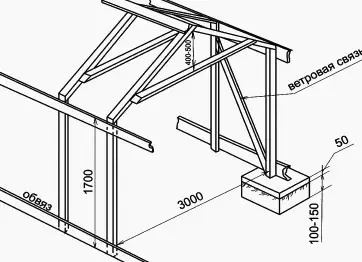

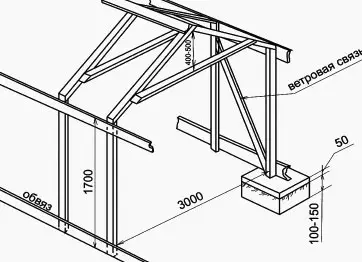

Figure 1. Scheme for wooden frame.

The dimensions of the manufactured structure - 6x4 m. The product is covered with polycarbonate. For the manufacture of such a greenhouse, you will need to perform the following steps:

- First of all, it will be necessary to build a foundation. To do this, you should drill a soil by 50-60 cm, pour pillars through pre-installed studs.

- On the pillars you need to assemble the strapping from the larch timber with dimensions of 1x1 m. The strapping is attracted with nuts with washers to the columns.

- A framework is erected according to the scheme and is covered with studs. The scheme of such a design with all the necessary steps can be seen in Fig. 2.

Teklitsa from the tree in Mittlider

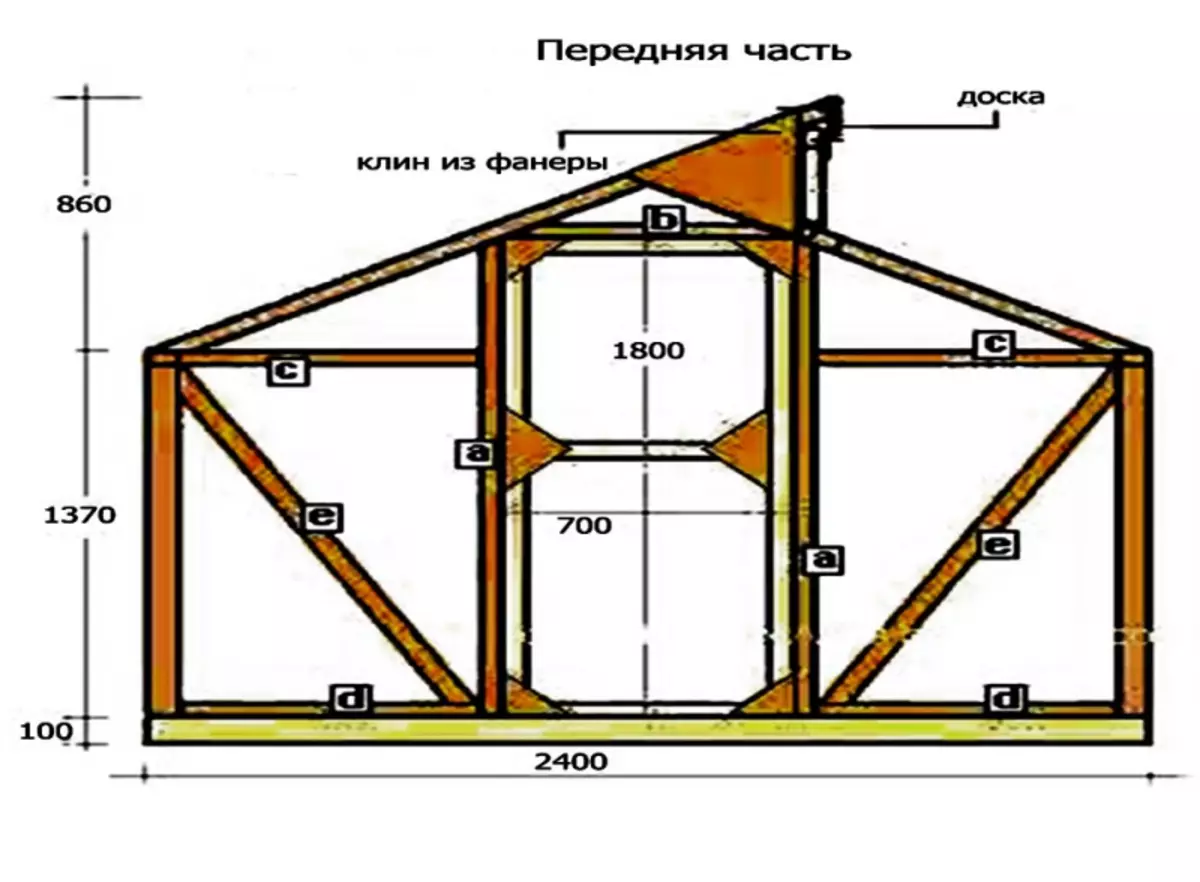

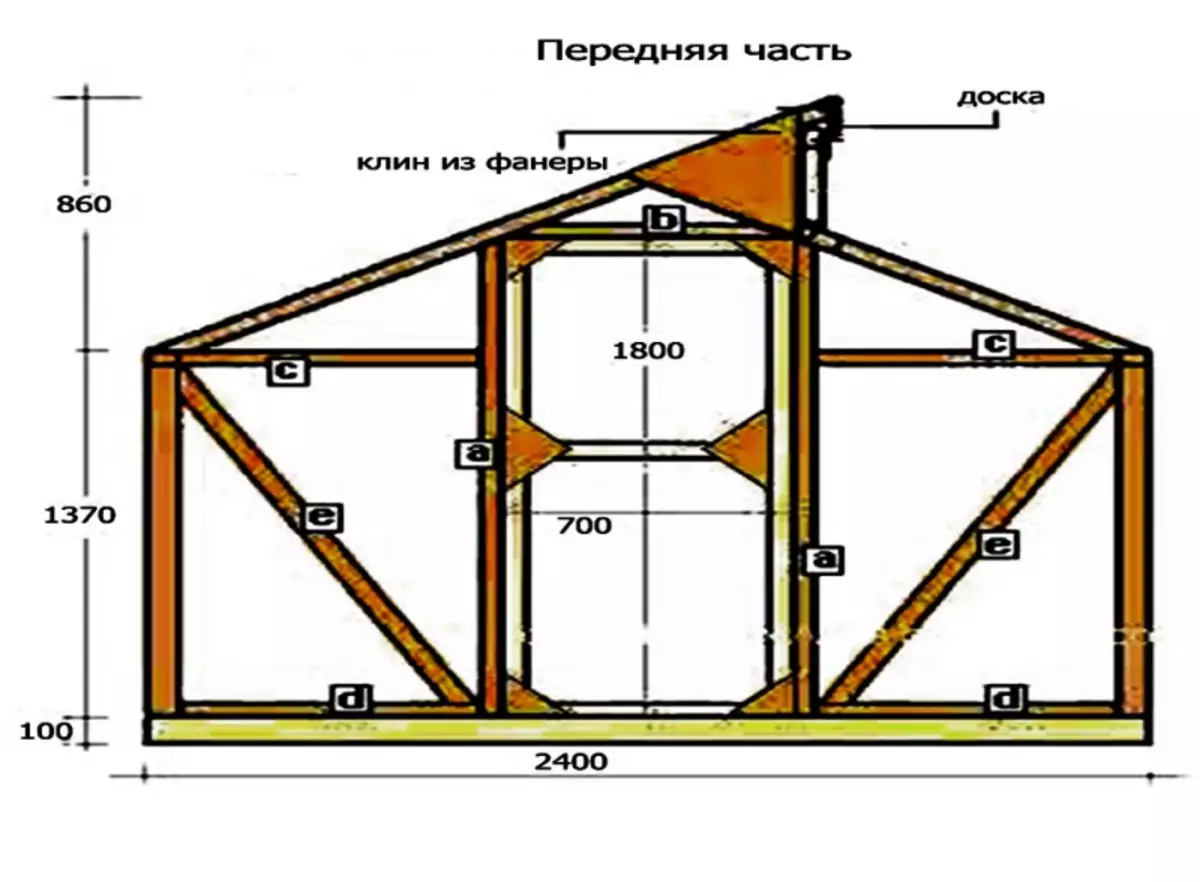

The design that will be built has the following dimensions: width - 4 m, length - 8.4 m, height in a skate - 3.1 m. The design will have several slopes of different heights and vents that are located under the skate.

Figure 2. Greenhouse framework scheme on wooden frame base.

To run the design, you will need to use the boards 0.5x1 m. The construction process is as follows:

- The first thing is the foundation. For the greenhouses of this type, a monolithic tape 35x20 cm is suitable, which is fixed with reinforcement 8x4 mm. Outside it is necessary to impregnate it with a special means to ensure that the base does not crumble in the future. The design can be littered with natural stone.

- Frame is installed. Stands should be mounted every 70 cm.

- In the upper part of the greenhouses are manufactured by the vehicles. You can provide automation to open them.

- Polycarbonate is fixed. In this case, it is important not to leave the slots.

- At the end, it is necessary to start a water supply in the greenhouse, set the container of large sizes and dilute the pipes into several beds under the drip watering.

For the manufacture of such a greenhouse design, you will need to purchase approximately 2000 boards of 0.5x1 m. To build doors and subcords, you will need to purchase more small sizes - 30x50 cm and 50x70 cm.

Article on the topic: Making Woods and Longs with your own hands

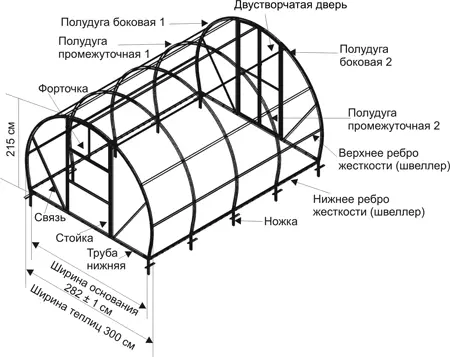

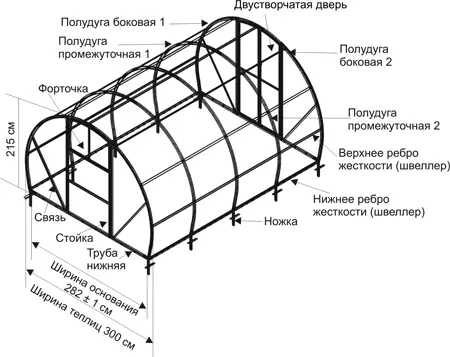

How to make a greenhouse under polycarbonate?

In this case, the framework will be manufactured from wooden bars 45x45 cm. The greenhouse length is 8 m, the width is about 2.8 m. It can be found in the installation of two doors and several vents.

There should be no more than 1 m between the racks.

Technology building a greenhouse in Mittlider.

Each farm should rely on several racks. An exception is the central stand.

The sequence of actions will be as follows:

- The blockage in this case will be carried out by using a metal of 45x45 mm or 50x50 mm. With the help of the grinder, the shelves should be made at 12 cm at right angles. Thus, it is possible to get a base for which the strapping will be attached.

- After that, you need to paint the corner several times with anti-corrosion paint.

- Next, it is necessary to score bars to the ground, check their location by the construction level, after which to fix the strains of the strapping by self-drawing, docking them with each other.

- All joints need to enhance the metal plate.

- The lower strapping throughout the perimeter is isolated by galvanized and plunged into the ground.

- Next on the roof it will be necessary to secure polycarbonate with screws with rubber beds, all other elements are fixed by using the press washer.

- Face parts of polycarbonate should be closed with a plastic corner. The sheets are installed in the shoulder, after which they are treated with silicone sealant at the edges.

- The lower strapping is processed into several layers with an antiseptic agent, then paint.

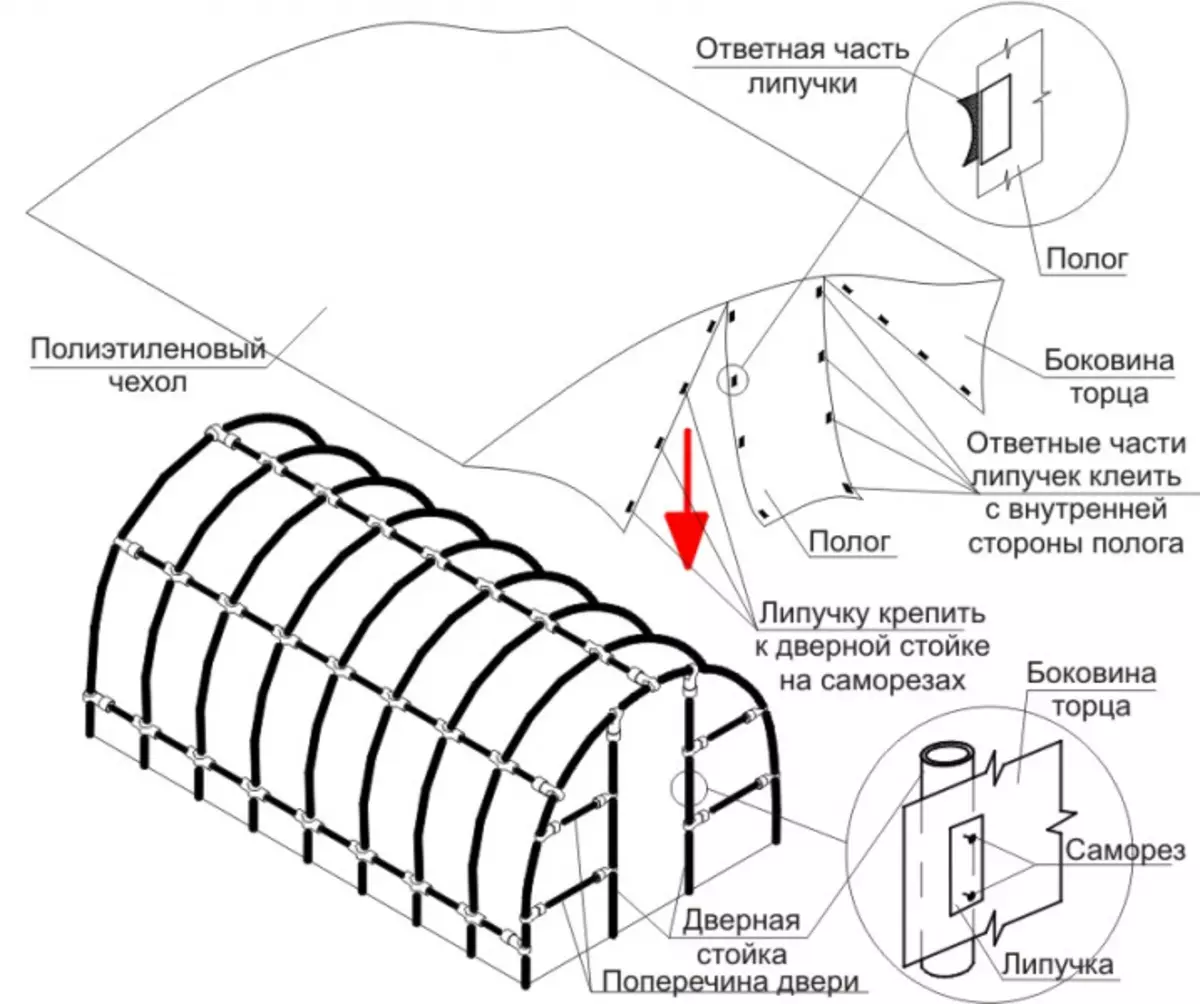

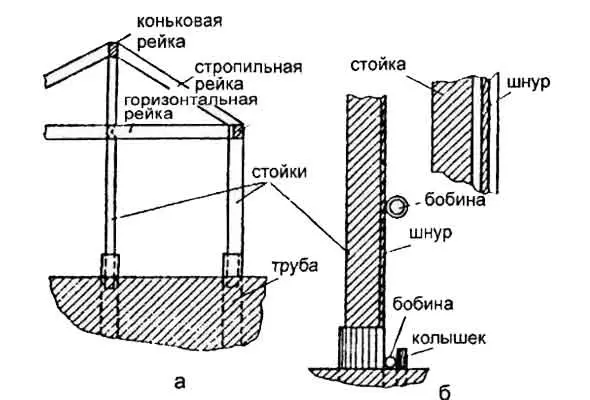

How to make greenhouses do it yourself under the film?

A diagram of a metal frame device for a greenhouse greenhouse.

In this case, the greenhouse will be covered with a light film. The procedure will be as follows:

- Reliable base is manufactured. The design will have a small weight, therefore you can cook ordinary self-made piles of small sizes. They can be made of metal corners of 50x50 mm. The length of the elements should be 90 cm.

- Piles are covered with primer in several layers and clogged into the ground.

- Piles will need to be aligned with the use of a laser level. After that, you can move to the frame assembly.

- Set rafter structures. In this case, you can use the phaneer with a thickness of 8 mm, which is fastened with PVA and self-drawing glue.

- At the next stage you need to install flights for the beds. It is best to use slate with a thickness of 10 mm. From the side of the street near Schifer, you can additionally lay foam.

- After that, painting the crates. It should be remembered that the boards to painting will need to be treated with an antiseptic agent. Paint should be applied in several layers.

- An assembly of the frames for the pedigrees and doors is made.

- The whole design is covered with lightweight film.

- In the very greenhouse, it will be necessary to pull the cables in order to be able to tie the plants.

- Additionally, it is possible to mount systems of watering and automatic ventilation.

- If the greenhouse construction is built in the cold region, you can pull another layer of the film inside it, consolidating it to the crate with a construction stapler. Even in the case of the use of budget films, the effect can be immediately noticed.

Article on the topic: Pressure in heating radiators

How to build a portable greenhouse on foundation blocks?

Film mounting scheme for PVC greenhouse.

The design can be disassembled and transferred due to its low weight. If the greenhouse needs to be transferred from one place to another, you can build a similar design. The basis will consist of several bars of 15x15 cm. Make it can be as follows:

- First of all, you need to dig the pit to the sand layer, pour sand and gravel into it, carefully tamper and put blocks from concrete.

- Next, you need to handle bars with an antiseptic agent. After the remedy is dry, wood needs to be deceived from two sides by bitumen.

- Frame is installed, after which it is processed by the same antiseptic agent.

- In the corners of the design, it is necessary to fix the disclosure with a height of 1 m.

- The template rafter is manufactured, with which it will be possible in the future with ease of manufacture all the others.

- Prepared and installed racks.

- After the roof is built, it will be necessary to paint the face part of the design.

- The wooden greenhouse is covered with a polycarbonate with a thickness of 5-8 mm.

- To insulate the design, extruded polystyrene foams can be paved inside it. From the outside, cement blocks are established.

What is better to cover the greenhouse?

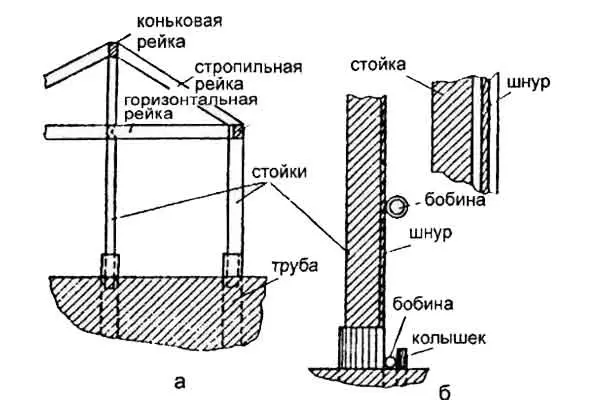

Scheme of fastening of a film wooden greenhouse: A - mounting diagram of racks, B - diagram of a device for lifting the film.

When the greenhouse design is ready, you will need to decide on the material for its coverage. A durable frame can withstand any weight, therefore you can choose both glass and a film or other materials. The choice must be made on the basis of the practicality and quality of the material. The following materials can be used:

- Film. The cover should be performed consistently, gradually passing through the skat on one side to another. Phased film is fixed to the frame. The corner of the greenhouse structure is recommended to cover the visor, since the film is often damaged and moisture and cold air gets through defects.

- Glass. If it was decided to cover the greenhouse with glass, you should acquire special stops and strokes. The glass is best ordering after a complete installation of the crate when the exact dimensions of the cells are known. Fastening material should be firmly. Seams can be treated with silicone or sealant to ensure the tightness of the design and exclude drafts.

- Polycarbonate. Turn the greenhouse from the tree with polycarbonate quickly and simple. To do this, use special racks and profiles, as well as fasteners that can go complied with polycarbonate plates. This material is the most practical and modern, therefore it is recommended to cover the design with it.

After the greenhouse housing is covered with the selected material, the design will need to be sealed, install the heating and lighting devices in it, carry out water for watering, arrange a ventilation system.

To date, there is a sufficiently large number of different chickens of wood. You need to choose from personal preferences. Make a greenhouse with your own hands is easy if you consider all existing nuances, observe the sequence of actions and have the necessary tools and materials for work.