The plaster of internal and outer walls is the most time-consuming process, and it will be very sorry if the work done will go to the pump. That is why a mixture for plaster walls plays a very important role. You can prepare construction mixtures and do it yourself. To do this, you will need to choose the necessary ingredients, sifted sand, keep all the proportions and mix them with water to obtain a homogeneous mass. This process takes quite a lot of time and the mixture for plastering walls as a result may be poor quality.

Mix for plastering works

But, fortunately, the manufacturers of building solutions thought that dry compounds were made for plastering work, your task is to correctly choose the composition for internal or external work.

How to choose a mixture for work?

The selection of plaster depends on the technical characteristics of the surface, the practicality of the solution in the use, and the cost of time that you will need to perform work. An equally important point is the cost of the material.

So as not to be mistaken and make the right choice, you need to know what kind of mixtures there are, to know their technical characteristics and for which they are used.

Mix for plaster

If you are coming outdoor work on the facade finishing, you will have a choice of two options - to stay on cement or prepare cement-limestone.

For internal works, it is also possible to use masses based on cement, and the third option appears - plaster based on plaster. Of the three options, make the right choice to become much more complicated. To make it easier for you, in the article we will introduce you to the pros and cons of each category in more detail.

Varieties of dry construction mixtures for plastering works

Dry building mixture

Depending on the ingredients, dry building mixtures are manufactured in four types:

- cement;

- cement-lime;

- gypsum;

- Adhesive plaster solutions.

Article on the topic: Strings for curtains and string curtains: secrets of installation and features of operation

The main component of cement plaster is cement, and the binding component is sand.

The advantage of such a mixture can be called:

- dry mix is universal for both exterior and internal works;

- You can prepare a solution immediately, because the technical characteristics of the components allow the mass to maintain their initial consistency for a long time;

- The surface resulting as a result of work is characterized by a high level of strength;

- cheapness.

Count minuses can be attributed:

- Bad connection with a smooth concrete surface;

- Hardening cement takes too much time (for further work it will be possible to start not earlier than after 14 days);

- The surface requires putty;

- The need is high levels of humidity in the air or in artificial moisture;

- gravity in the performance of work;

- After work, it takes a good cleaning, because during the application of the solution, its drops fall on the floor, and in the process of drying, such "garbage" adversely affects human health.

Dry mix for plastering works

To prepare the second composition of the mixture, you need to mix 3 components: cement, sand and lime.

Such a compound has the following advantages:

- Mass can be used for internal and external finishes, as well as in rooms with a high moisture level;

- technical peculiarity - a mixture of the bacteria reproduction and prevents the development of fungal infections;

- The mass is distinguished by its elasticity and convenient to apply;

- Fixed well on the wall surface.

Disadvantages:

- So that the surface has become absolutely dry, it takes a lot of time - from 2.5 to 4 months;

- Working with such material requires strict adherence to all technical rules and norms, and the violation of technology can provoke cracks;

- This is a substance, or rather, its dust, very poorly affect health, and when a drop of substances in the skin, there may be irritation or an allergic reaction.

To make a gypsum mixture for plastering, plaster and various dry mineral supplements will be required.

Such a substance has the following advantages:

- The mass quickly enhances and reduces the duration of the process to extremely short time limits;

- The characteristic of the material allows not to put the walls before pasting wallpaper;

- The solution has a good clutch with the surface of the wall and plasticity;

- Plastering is enough to apply in 1-2 layers;

- Such work is practically not dusty, compared with cement solutions;

- The finished surface after the misfortune does not succumb to the shrinkage and is not cracking.

Article on the topic: Methods and types of pasting wallpaper of two types

By cons of the material can be written:

- Low "viability" of a mixed solution;

- The treated surface is easy to mechanically exposed to high humidity, so it is rarely used for external work.

Such a kind of plaster, like glue, in composition has: cement, sand, polymer fillers and special fibers. Most often, such material is used for mounting work with insulation.

Dry adhesive plaster is characterized by a high cost, so it is extremely rare for aligning structures.

Also, dry building mixes can be divided into additional categories of 3 types, which are shown in the table below.

Dry building mixes for plastering works

| The size Filler | Purpose Mixes | Type of binder Substances |

| Large fractional | Masonry work | Cement |

| Melko fractional | Plastering works on internal and external surfaces | Gypsum |

| Middle fractional | Putty work | Combined compounds |

| Glue | Polymer binder components | |

| Battle | ||

| For floor screed | ||

| For waterproofing |

What should I pay attention to the purchase of a mixture?

Dry mix

Chief Council - Do not buy mixes, in the quality and characteristics of which you are not sure!

Now the German firm "Knauf" is now highly popular, which produces sufficiently high-quality mixtures. Of course, the price category on them higher than on domestic brands.

Among the domestic manufacturers, masters about such firms, as "prospectors", "Unice", "Solve" and "Volma" are not bad.

According to the technical and qualitative characteristics, domestic brands are not inferior to German material, and when buying a large number of packages, the savings becomes tangible.

Please note that for finishing walls of foam concrete, due to their porous texture, it is better to use gypsum solutions. But because of good moisture absorption, in the process of work, this finishing material will have to moisten with water several times.

To cover wooden surfaces, it is better to make it yourself a mixture with lime and cement.

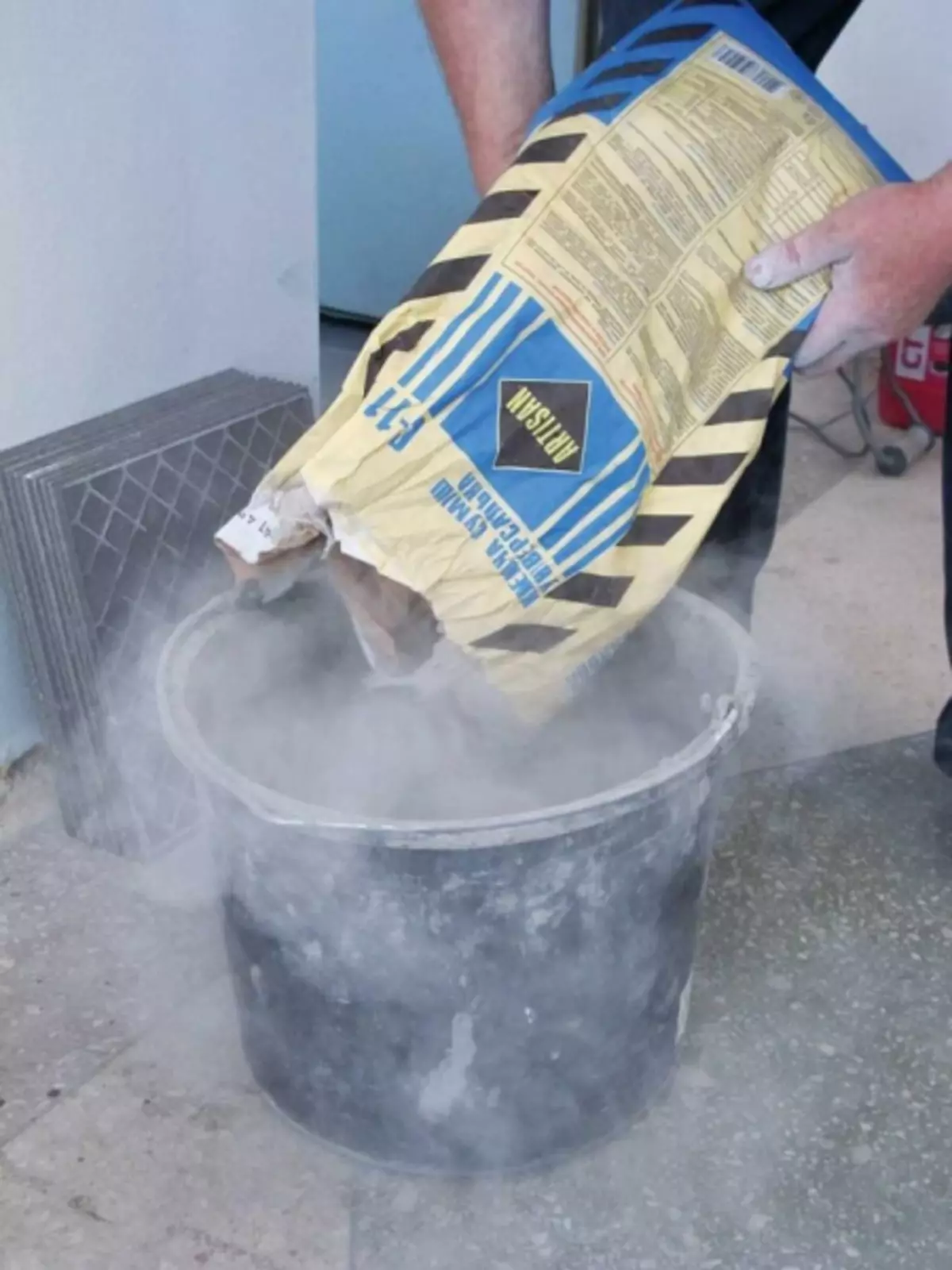

Preparing a plaster mix

At its price, the plaster dry mixture exceeds cement, but if you take into account their flow to 1m2, then the difference becomes not so significant (if the thickness of the coating is 10mm, 1 m2 of the gypsum will require 10 kg, and the cement solution is ≈15kg).

Do not buy dry mixes in large quantities. Now there are many scams on the market that deliver fakes or poor-quality goods.

Buy to start 1-2 packages, test them with your own hands and make sure that they are specific. Sometimes, it happens that dry gypsum mixes due to improper storage are set up 10 minutes after the preparation of the solution, and the cement dry mixture is not always sold with the proper composition of the components and can be drained from the wall.

A high-quality dry mix is always sold in a three-layer packaging, one of the intermediate tiers should be a film. Also carefully refer to the expiration date of the mixture, which is applied to the packaging.

The cost of dry plaster

Preparation of plastering from dry construction mixture

The variety of mixtures and its technical characteristics are largely affected by the price policy. As we have already mentioned, much depends on the cheapness of the basics of dry plaster and the possible shrinkage of the material.

Dry cement-sand mixture in packaging 25kg can do in the area of 150-400 rubles. The gypsum mass will cost more - about 200-500 rubles. The most expensive is the decorative dry plaster for which 400-800 rubles will have to give.

Although sometimes it seems to do everything with your own hands it turns out less expensive, however, the practicality and confidence that the dry mixture will provide you is worth spent money. This material allows you to be confident in the final result and does not require any specific skills. All proportions are indicated on the package, it is enough to dissolve the mixture only with their own hands in the correct proportion to water and the solution is ready, you can start plastering.

Article on the topic: From what to make walls in the bathroom