The staircase is an integral part of the country house, it allows you to safely move between floors and rooms, and also performs aesthetic function. That is why the staircase should be stylish, convenient and multifunctional, regardless of the model you chose.

A spiral staircase made of wood, made with their own hands, will become an excellent addition to the interior of the living room or hallway. With self-assembly of this product, it is especially important to take into account all security requirements, typical calculations and room features.

A distinctive feature of a spiral staircase is lightness and compactness. Compared to the route, it has a wide variety of forms and sizes, as well as the possibility of combining materials. In this article, we will look at the main stages of the construction of a screw staircase, namely how to do measurements to do, carry out the installation and installation of the support. Compliance with these items will allow you to avoid mistakes and save money on the challenge of a professional brigade.

Production features

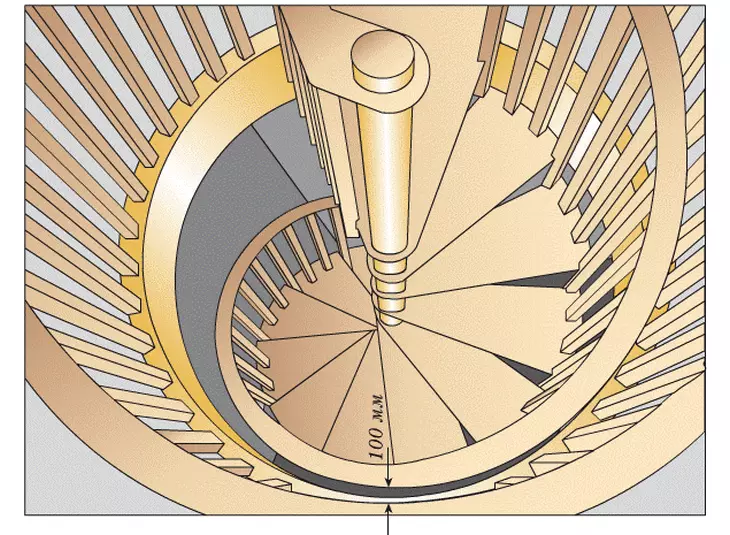

A spiral staircase is distinguished by small dimensions and an intricate form, in connection with which its manufacturer has a number of features. First of all, it should be determined that it is the considered element of the interior. From above, the base of the stairs resembles a peculiar petal with a slightly rounded corner.

Thanks to its unique parameters, the design takes at least a place in the house (it can take just one square meter).

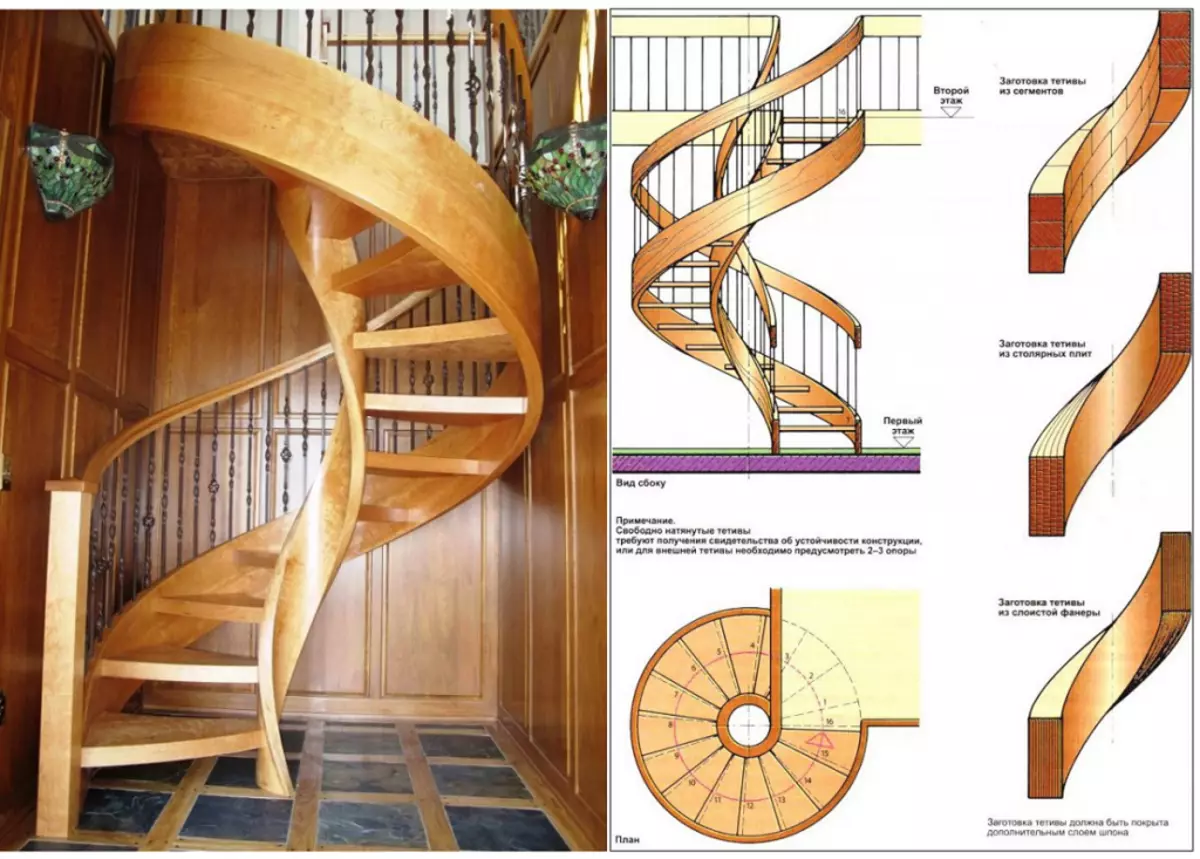

If you plan to build a screw transition from a tree or metal with your own hands, then you need to make a detailed drawing in advance. This will allow you to carry out installation work much faster and will save from catastrophic errors, because incorrectly completed measurements can cause an arbitraration of the finished product.

This type of installation work also involves the study of technology and characteristics of the process, preparation of the necessary materials and devices. To date, stair structures are made from different wood breeds (maple, oak and belant are most popular with the most popular with sheet metal.

Such structures save free space in the house due to their small size. So, with the width of the steps in one meter, the ladder diameter does not exceed two and a half meters. In turn, the product has an angle of inclination in forty-five degrees, which is the optimal solution for this form.

Note! Screw staircases have pretty narrow steps, so the tenants of the house must be extremely careful when moving (especially this is relevant to families with young children and older people).

Most designers converge in the opinion that it is not necessary to install screw staircases in rooms with intense movement. They are much better suitable for two-storey apartments or small country houses.

Advantages and shortcomings of screw stairs

In the manufacture of such an overted interior element, as a staircase, it is worth considering the technical and operational features of your chosen model. Like any design, the spiral staircase has pros and cons of use.

The advantages of such products include the following important aspects:

- Small sizes (thanks to this, you can visually raise a low ceiling, as well as zonate a small room).

- Since the screw transitions do not occupy a lot of space on the first floor, the formation of a large opening on the ceiling is not required (which saves the area between the floors).

- The spiral staircase can be used as an additional as an internal and outdoor design of the house.

- The cost of manufacturing the screw staircase is several times less than the construction of the march design.

- The feature of the screw staircase is an unusual form, which gives exclusivity to the interior of the house and makes the room very stylish and spectacular.

Article on the topic: Making a metal staircase with their own hands (assembly guide)

A spiral staircase has certain disadvantages of operation, the main of which is a low level of safety when lifting or descent. Another negative point can be considered the impossibility of transporting large-sized items (furniture, technicians) to the second floor.

Use the screw staircase is better as an additional transition to the attic or the attic, the main structure must be a march model.

To protect yourself and their loved ones, experts recommend deciding on the type of product in the first stages of the construction of the house. So, if you decide on a screw staircase, it is better to place a bedroom on the second floor or other premises of not frequent use.

What you need to know before starting work?

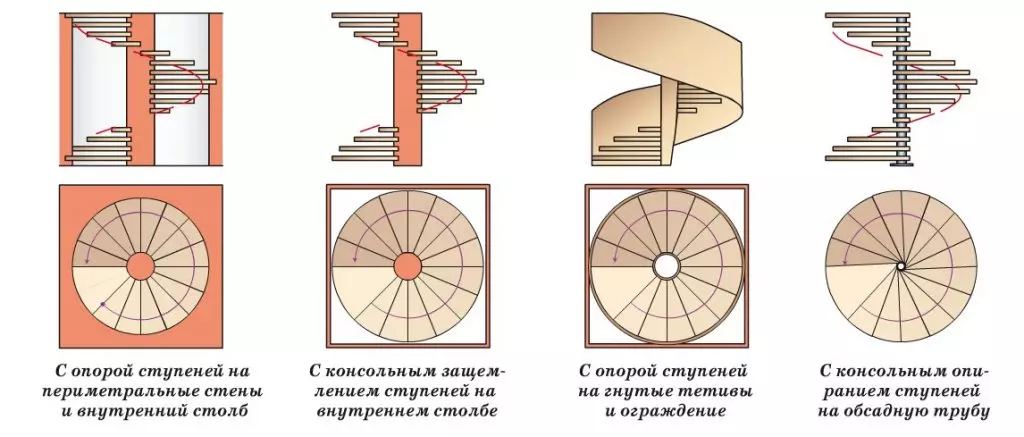

There are several types of screw staircases, the choice depends on your personal preferences, places of installation and features of the room. To choose the best option, look at the photo below, where the schemes of the main four structures are presented, each of which is characterized by the fastening method.

However, it is worth noting that in all varieties of the risers (if they are present) and the steps are attached in such a way that the result is something like a thread of a standard screw. When considering the finished product from above, the form of a span becomes clear. Depending on the direction of threading of a conventional screw, the staircase will either in the form of a circle or in the form of a polygon.

The polygonal version of the staircase is becoming increasingly popular, this design is installed at the wall and gives the room a complete appearance.

Before starting installation work, we recommend paying attention to the advice of professional builders specializing in the construction of staircases:

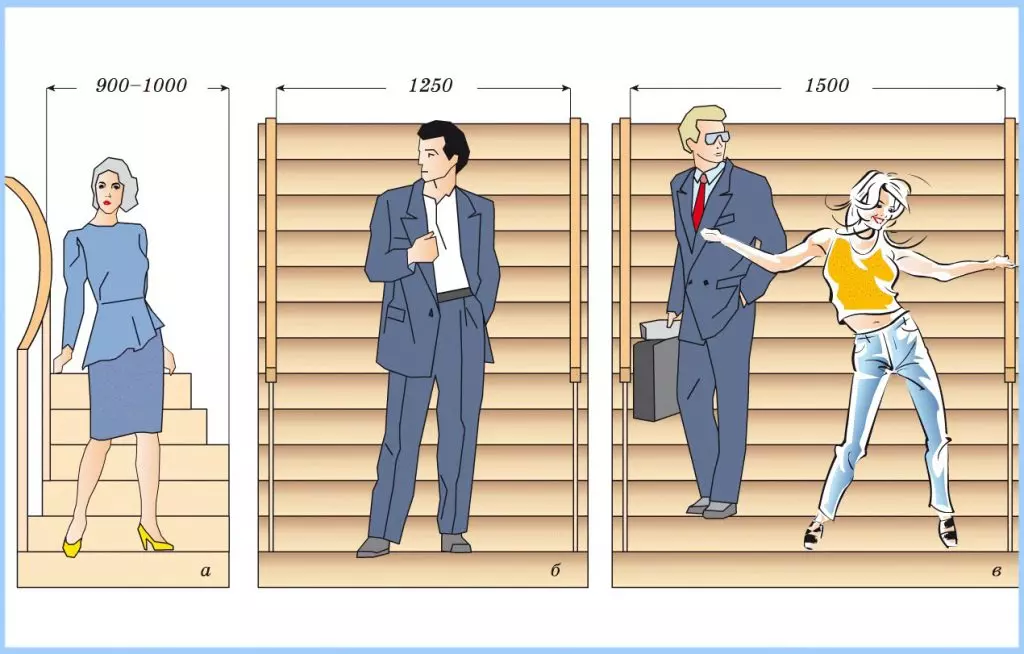

- For comfortable movement between the first and second floors, the minimum width of the staircase must be one meter.

- The most budget and optimal option is a screw construction, the steps of which are attached to the screw orders with balusters and at the same time fixed on the carrier support.

- The most reliable is a screw construction with betented handrails, which are attached to steps and risers (there is no central support).

What materials may be needed?

The strength and durability of the staircase is primarily affected by the main material. So, more and more often in the manufacture of the screw staircase, asbetic or metal pipe is used. The carrier element made of such material allows you to increase the life of the product and prevent the negative effects of mechanical impact.

Steps that, in turn, can be made from completely different materials (wood, stone or concrete) are attached to the metal pipe with welding. For the railil, solid wood solids are excellent, combined options look especially effectively (when the noble wood shall be decorative glass elements).

Choosing a material for the production of a screw staircase, do not forget about the features of the interior of the room. For a country house in a classic style, wooden models are suitable, and for a modern living room - metal products, but with stone steps.

Designing stairs

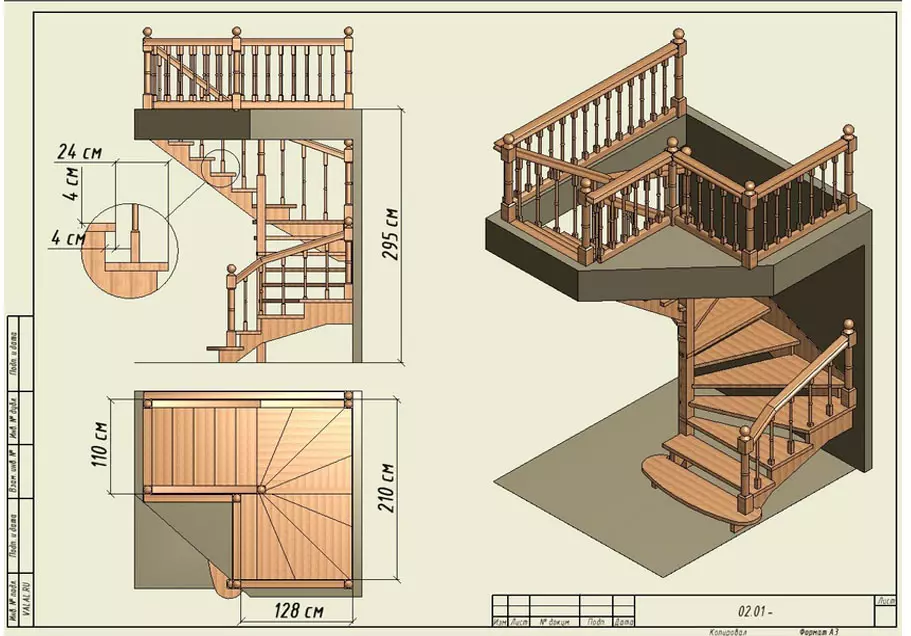

By drawing up a drawing, you need to decide in advance how you will use free space. If you are going to independently do all the measurements and calculations of the screw staircase, before drawing up the plan, you need to take into account the main design features of this element of the interior. Below is a typical version of the screw staircase.

Article on the topic: Features of stainless steel stairs: species and advantages [necessary components]

For a private house with young children and older people, it also follows:

- equip a staircase for additional protection (comfortable handles, anti-slip track);

- eliminate or reduce the amount of dangerous elements;

- Increase the safety of the design, correctly picking materials and make up the plan.

On video: Ladder design errors in a wooden house.

Features of the calculation (drawing production)

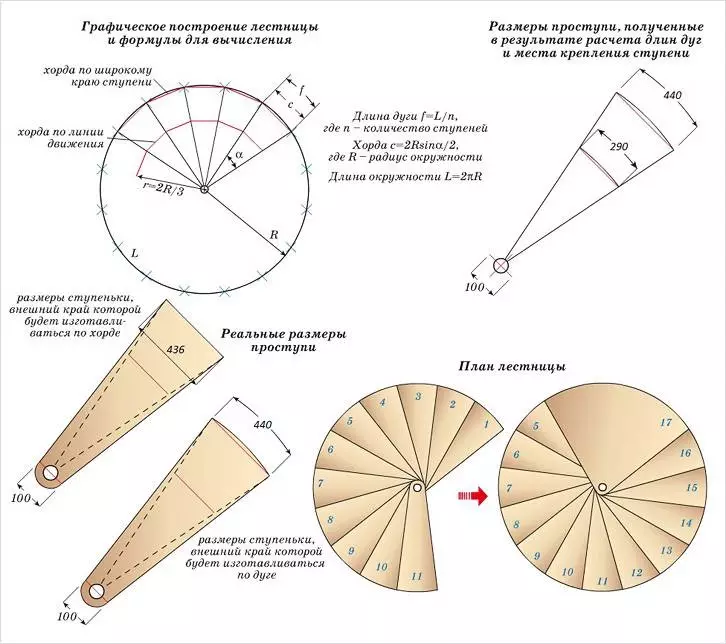

This dimensional interior element requires a detailed scheme. You can perform the drawing with your own hands or use the services of specialists (this will avoid many mistakes, to cope with which the beginning master is not under power).

Experts recommend starting the first stage of work from the project of the first floor. In this document, you should specify where the installation will be installed, as well as the exact dimensions (length, width, tilt) of the staircase, according to the scale installed.

It is necessary to calculate and describe how to change the form of steps when using swivels. It is necessary to accurately observe all the parameters, in the context, all design elements must be combined with each other. You should also compile a separate scheme in which the circular corners of the flight lift will be shown.

Design calculation

When measurements of the future product, it is especially important to comply with step-by-step instructions and a pre-created diagram. To avoid typical errors, pay attention to these rules:

- For a convenient passage of a person, the width of the staircase march should be at least 900-1000 mm - for screw construction, large indicators are allowed only in the case of conventional (straight) stairs.

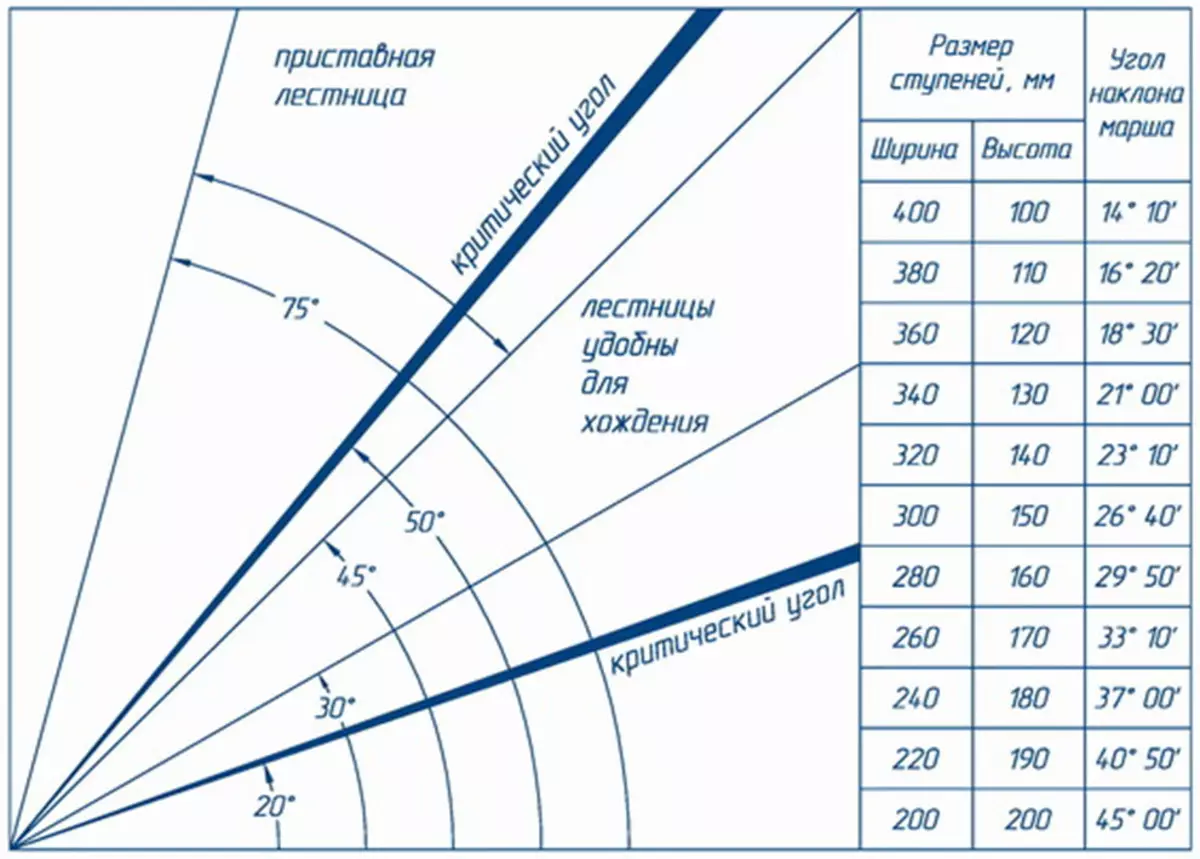

- The optimal angle of inclination of the product is 45 degrees. The smaller this figure, the more the place will take the staircase.

- The optimal distance between the handrail and the edge of the opening is not less than 100 mm.

Calculation of steps

When drawing up a project of the future product, it is necessary to consider the parameters of the finished elements and their number. Thus, the thickness of the steps should be at least five centimeters with standard staircase sizes. To determine the required number of steps, you need to learn the height of the future staircase (H = distance from the floor to the ceiling + the thickness of the inter-storey overlap).

Suppose the height of the future staircase (H) - 3 m. The recommended height of each step (S) is 18-22 cm. Take the average value - 20 cm (i.e. s = 0.2 m). To determine the number of steps, the height of the stairs is divided into height of steps, H: S = 3: 0.2 = 15. As a result, it turns out that we need 15 steps.

The sizes of each sticking for the screw staircase are calculated by means of a special formula (see the photo below).

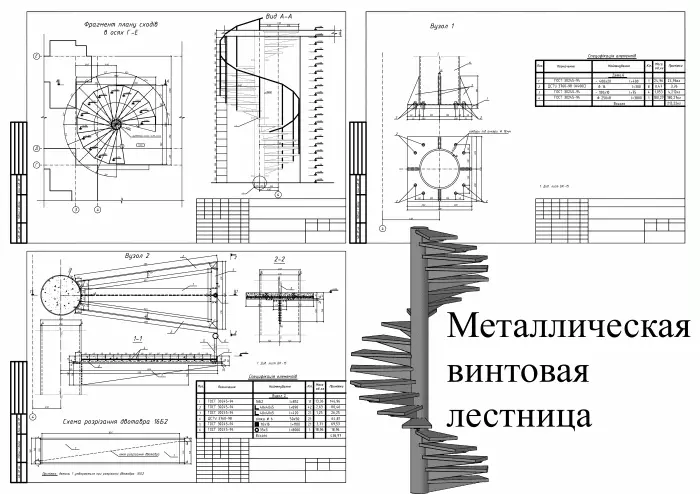

Drawings of screw wooden stairs

The circular staircase from the tree is in solid demand due to the minimum cost and compactness of the design. Products made of wood give the room with solidity and are characterized by increased safety (compared to metal models). A beginner master will be able to make a wooden staircase, the main thing is to correctly create a drawing or use the ready-made examples. We expect that the proposed options will help you in your work.

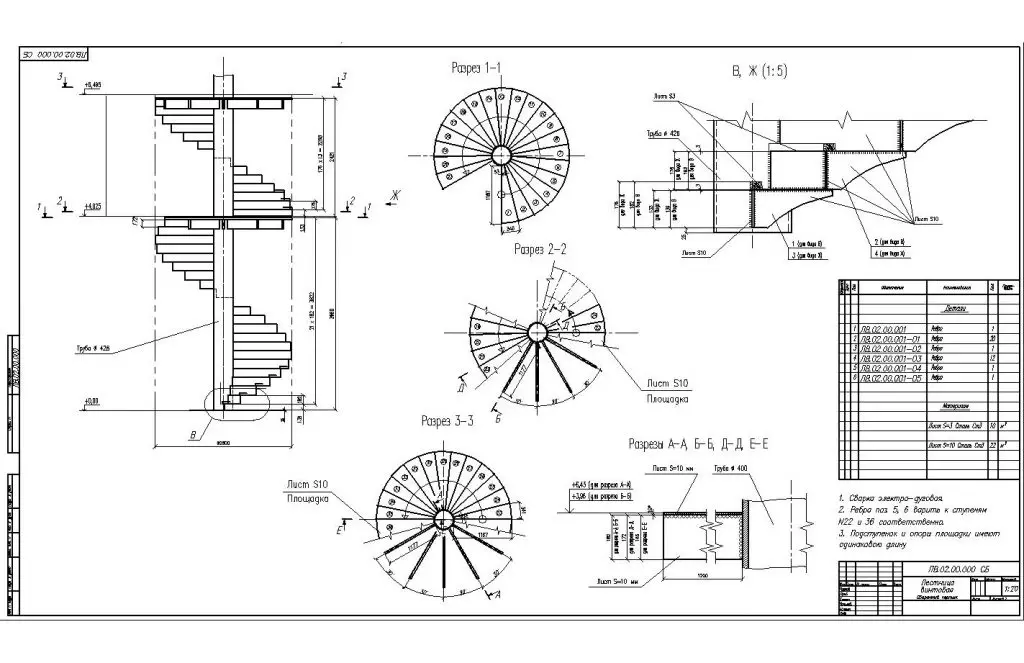

Drawings of screw metal stairs

Screw (or round) Metal staircase has a number of advantages. First of all, it is the fire resistance of the design, as well as simplicity of installation and long service life. Distinctive features of such circular products are modern design and the possibility of combining various materials.

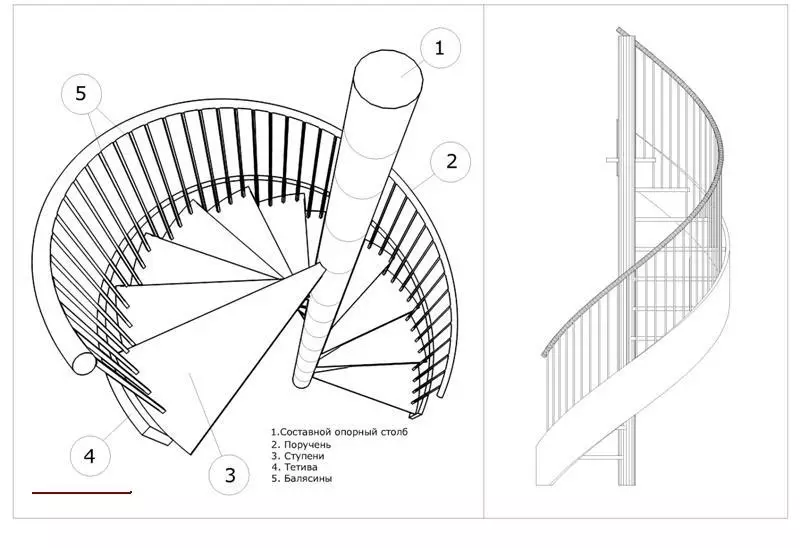

Externally, the drawing of the screw staircase from the metal is not much different from the previous example, however, there are nuances here. So, it is possible to properly make such a design only if the step-by-step instructions and special technology are observed. The system assembly implies the installation of the central rack, fastening the bushings, washers and steps.

Article on the topic: Features forged stairs: species, advantages and manufacturing technology | +55 photos

Montage Guide

Now in stores you can find ready-made screw structures, the assembly of which does not represent a special complexity. In this case, the novice master needs to be only followed by step-by-step instructions attached to the product, and check the reliability of fastening the components (steps, supports, railings). It is also possible to use samples of wood steps - they can be installed with any parameters of the product. However, do not forget to carefully stabbing all the edges at the end of work.Installing support

Supporting screw staircase can be concrete, steel, wooden or brick poles. Each of the elements is bonded with each other with bolts and occasionally couplings. As a result, such a reference rack should be obtained, which is able to withstand the weight of the finished product and man.

The support column, from which material it is made, is connected to the lower and upper part of the stairs at the same time. The dimensions of this element may vary, depending on the variety. The diameter of concrete and wooden racks is 15-20 cm, the diameter of the metal support is not more than 10 cm.

Speaking about the manufacture and installation of the taisle with your own hands, you need to take into account the complexity of the process of giving the wooden detail of the bent form. For this purpose, a special technology is used, which involves wringing the tree, the formation of the necessary proportions and drying.

The optimal option in the independent production of the screw staircase is the compound of several parts into one of the tutor.

Installation of steps

For comfortable movement between floors, it is important to correctly arrange the axis. When choosing a metal staircase, a frame of the required form is mounted using metal corners. The latter are welded to the support post in the form of direct plates. You can also fight three metal profiles among themselves, subsequently there should be a peculiar stand for the step.

As for the entire wooden staircase, it is easier to make wedge-shaped steps with a hole in a narrow part and ride them on the support rod. You can also purchase ready-made components for the assembly of the modular staircase.

Fences and railing

The penultimate stage of the construction of the screw staircase involves the installation of the fence. In the case of screw models, it serves as additional protection, and also performs a decorative function. Most often, the fence is made of metal pipes or forged items, which looks very spectacular and makes the interior of the house more stylish.

If you plan to build a wooden screw staircase, then pay attention to the balusters and railing from expensive wood breeds. However, the installation of rounded railing is very difficult to carry out - for this you need to soak in advance and dry the items. That is why professionals advise to use imitation for wood (PVC-based products).

Final work

In the case of a wooden screw staircase, the final stage is painting. If you use beech as the main material, this process requires special care (to save the natural texture). First of all, the details must be cleaned with sandpaper, spending and coat with a veneer. Next, you should apply two layers of parquet varnish, it will avoid the abrasion of the surface.

The manufacture of a spiral staircase is a rather long and responsible process. However, it can be done even by the novice master. Compliance with the technical norms, security rules and accurate instructions for assembling and installing the structure will make it possible to achieve an excellent result. If you doubt or do not have sufficient experience in the construction sector, it is better to seek help from specialists.

Examples of the assembly of the screw staircase with wooden steps (2 video)

Beautiful and unusual stairs models (46 photos)