In the process of long-term operation of any boiler installation, the boiler and the heat exchanger is constantly in contact with water containing a large amount of dissolved substances. It is these substances - salts of iron and others - settle on the hot surfaces of parts, which can lead to the formation of unwanted scale.

There are three methods for washing the boiler: hydrodynamic, mechanical, complex.

Scale noticeably reduces the thermal conductivity of the entire system, which leads to an increase in electricity costs, to a violation of the proper circulation of the coolant through the boiler.

That is why the washing of boilers from scale is a very important procedure that it periodically needs to be performed.

Main types of boiler flushing

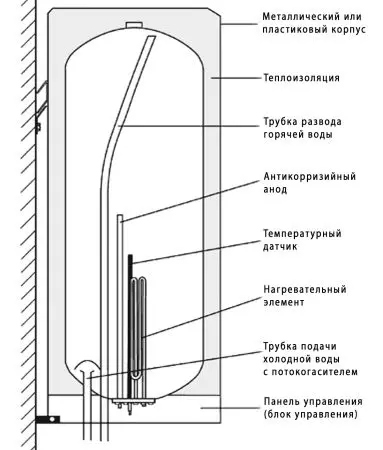

Cleaning scheme of the boiler.

Under the washing of boilers, it is necessary to understand a whole range of events, during which, with the help of physical or chemical methods from the boiler, the axial scale is completely removed. Today, two main types are distinguished: repair and regular. With regular flushes of boilers with parts of the entire boiler installation, a small amount of raised scale is removed. The repair operation is made much less often, that is, in cases where the regular flushing no longer helps.

With regular flushing there is no need to disassemble the system. All operation is carried out using special equipment. Thanks to this method, it is possible to prevent the occurrence of large amounts of scale. So you can prevent emergency situations. Regular flushing boilers It is important to carry out mechanical damage, associated with an increase in pressure inside the system due to blockages. Regular flushing should be carried out every few years, but under the conditions of constant operation of the heating system, this period is recommended to be reduced. This operation can be performed on the spot, which significantly reduces the cost of servicing boilers.

When repairing washing, you must fully disassemble the system. This procedure is carried out if the further operation of the system is estimated as unsafe. Such an operation is usually produced by the physical method, but the use of chemical washing is possible.

Article on the topic: Is it possible to glue the wallpaper on the water-mounted paint: painting wallpaper, video, how to stick, will the waterproof paint stick, photos

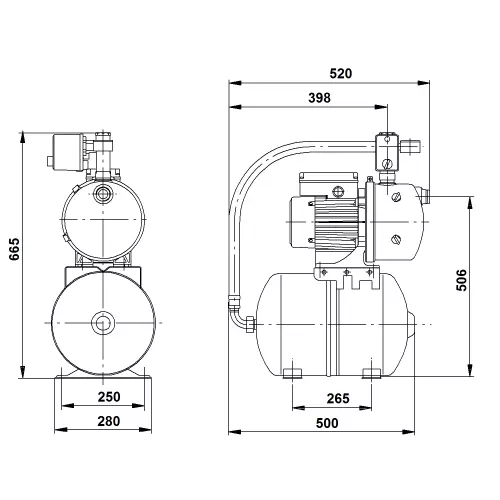

Special installations are used for flushing boilers, or so-called boosters. This installation is a comprehensive system that consists of two blocks. The work of such boosters that have a simple design is quite complex and requires accounting for many minor factors. Such factors should include the features of the design of the boiler installation itself, as well as the ability to adjust such parameters as the temperature and pressure of cleaning solutions in the system itself.

The principle of washing using boosters

Scheme of the boiler device.

The rinsing principle using boosters is as follows: a special cleaning agent for washing boilers is poured into the installation tank. Next, the booster through the existing drain holes is connected to the boiler installation, then the pump begins to operate, which distinguishes the tool for flushing into the boiler. This solution circulates along the entire system where it dissolves. Further, the whole solution is removed by the installation, everything is washed with water. That is, it can be argued that the main functional block of the booster is precisely the pump that performs a greater amount of all work on washing the boilers. In addition, other elements are also played by an important role: a tank for reagent, heating elements (TEN).

The booster tank is a hermetic container, which is made using chemical-resistant materials. This is a necessary condition for using the tank, because the container has a long contact with aggressive media. The booster should withstand high temperatures. Often the heating element is installed in the tank, a tubular electric heater. Its function lies in the heating of the solution for flushing boilers to a certain temperature. It is such systems with embedded Tanes that have the greatest efficiency and speed of work.

The main part of this installation is the pump. It provides the following work: feeding a cleaning solution from the tank of the installation itself into the system, high-quality pressure adjustment in the system, removing its fluid that has spent its fluid and the final stage - flushing the boiler with water.

Article on the topic: how to make a poftahin over the bed

The possibilities that the booster pump should have

Bower pump drawing.

Based on these functions, the booster pump must have the following features:

- The possibility of functioning when working with aggressive media. The pump must fully ensure isolation of aggressive fluids from the external environment.

- Ability to control pressure. When washing the boiler, some volume of gases begins to be distinguished, which begin to increase the pressure in the system, so the pump must have such an ability as a decrease in pressure.

- The pump must have a function of operation in a reversible stream mode. This reverse is required to remove the cleansing fluid from the boiler system. From this mode directly depends on the functioning of the entire system.

- The pump must be able to connect to the water supply. The final flushing stage consists in washing the system with tap water, which should come from the central water supply.

There are still a number of necessary equipment requirements (boosters). For example, the installation of the installation with the drain holes of the boiler system should be completely sealed. In addition, the cleansing solution should be subsequently neutralized before it is descent into sewage. Do not forget about the safety technique. This method is considered to be the most efficient and economical option for washing the boiler.

Repair flushing boilers should be used in rare cases when the scale of scale prevents the proper circulation of the coolant throughout the boiler system. This is due to the fact that the collapsible flushing of boilers is much more expensive than regular flushing, so it is used in particularly difficult situations.

Methods for washing the boiler

Today there are three ways to wash the boiler:

- hydrodynamic;

- mechanical;

- Comprehensive.

The scheme of the boiler structure.

The first and third method have the greatest efficiency. If regular flushing can be made independently, then the repair is better to trust the specialists, because there is quite high risk to damage this or that part of the boiler.

The mechanical flushing of the boiler system is to remove scale from contaminated elements using their physical processing using special tools. Metal scrapers or brushes can be used as such tools, as well as abroad heads with air or electrical drive.

Article on the topic: How to choose a kitchen sliding glass table?

With this form of washing, you need to pay special attention to the choice of tools. This is due to the fact that the risk of damage to the boiler itself is high. This cannot be allowed, because the process of corrosion of metal parts of the boiler system will noticeably accelerate. That is why it is necessary to strictly follow the rules of operation of the selected tools.

A less dangerous is the hydrodynamic clearance of boilers from scale. In this embodiment, the scale is removed from the parts of the boiler using a powerful water jet under high pressure. It is much higher productivity here than with the first way. This method is environmentally friendly, chemical and hazardous substances are not used here.

There is a third method - a complex flushing of boilers from scale. Here, as it is clear from the name, a combination of methods is used. For example, mechanical and chemical cleaning are used in the complex.

It is worth noting that the chemical flushing is as follows: contaminated parts are taken from the boiler system and are placed in a container with a cleaning solution for several hours. Next, they are washed under running water and mounted back to the system.

Basics of chemical reagents

Rinse the boiler with solutions based on salt, sulfur, phosphoric or nitric acid: they have high oxidative properties. To prepare this means, it is necessary to dilute the acid in a certain proportion to water.

And the collapsible, and the imbeption chemical flushing of the boiler from scale is carried out in several stages. Each of them will introduce additional doses of the reagent. This is due to the consumption of acid: enhancing the reaction with substances that are included in the composition of the acid, the acid loses its main oxidative properties.