Adaptations, often required in everyday life, can be made by our own, using the step-by-step instructions, thereby saving their own budget. If such a useful thing, like a stepladder with your own hands, will be made of wood, then its technical and safe characteristics will largely surpass the factory production that offers for use of lightweight aluminum structures.

Wooden stepladder made by her own hands will last no less than purchased products.

Wooden Wooden DIY

Read:- Wooden bars with a cross section 5x3 and a total length of 14 m;

- Metal steps: it can be both the knitting needles and plates, the total length is 10 m;

- Spokes for greater safety;

- Fasteners - nuts, bolts, screws;

- Plates for fastening legs with each other;

- Metal chain - 1 m 20 cm;

- Adhesive epoxy.

Instruments:

- Bulgarian or scissors for metal;

- saw-knife;

- wrench;

- drill;

- Roulette and marker.

Stages of work and their features

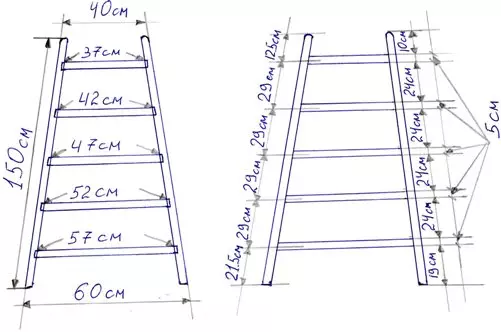

Wooden stepladder scheme.

Before you begin to make a stirrer, you should pounce an approximate sketch for its manufacture. It needs to immediately put all the sizes. Only a high qualification master can be allowed to work without a sketch. Do not think that the stepladder with their own hands is an object requiring a superficial relationship. First, the safety of working at height depends on it, secondly, it is very convenient when it is not necessary to constantly measure the workpieces, just look at the sketch.

Next cutting wood. It will take 4 blanks with a length of 175 cm each. Mostly the length is determined by the height of the works: if the stepladder is needed in the garden, then the trees should be proceeded, but it is also impossible to climb it too, other means will be needed. To work on the roof, this kind of staircase is used as a skating stepladder. It is distinguished by the fact that the second half of the clamshells dropped behind the roof, and bars are nourished for sustainability.

Article on the topic: Which coolant is suitable for aluminum radiators?

The ladder blanks are cut with the grinder. It is better to use a metal profile for this, rather than round elements, again for the safety of the working. Stop on a flat profile will be much more stable than a narrow cylinder. Billets must be in the same amount for both sides of the stepladder - factory are manufactured only on one side, but this model will have two working staircases. It is convenient if the work requires two people or to hard-to-reach places you need an approach immediately.

Drawing of stepladers with dimensions.

The length of such elements depends on the distance between the long side bars. The upper ends should be 40 cm from each other, and the bottom - by 60. There should be two billets in length in 57, 52, 47, 42, and 37 cm. That is, the distance between the steps is approximately 27 cm.

Then in the long elements, the holes are drilled along the diameter of the steps, if the elements are round, and the metal corners are fixed for flat. The depth of drilling should not be less than 2 cm. In the same way, the holes under the needles are somewhat lower. Then the design is collected without the use of bolts to see all the flaws and immediately correct. All elements are subjected to processing, because The material can be spoiled by mold or fungus.

Collect stairs. For this purpose, epoxy glue is poured into the recess, the wooden hammer is roughened. Then the knitting needles are mounted using fasteners that are tightened with nuts from two sides. Profile steps are attached with a wrench. After assembling the glue you need time, so the blanks are postponed for a day. If the installation was without him, then it's time to do plates.

One part of the elements is attached to the tree, and then the metal ears of the design are bonded with each other so that it can be freely folded or open. Perfectly fit for such a case plate from the mechanism of the old sofa.

Article on the topic: Miniature cross-strokes Schemes: Free Little pictures, Teapots with photos, download Rosehip Fruits

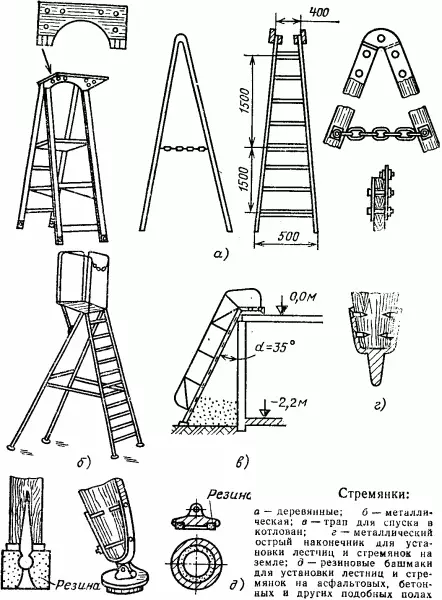

Types of stepladder.

Next, you need to take care of your own safety - the metal chain is cut by scissors into two parts and is screwed into the ends to the opposite elements. She will not allow the larger to decompose completely, if the legs begin to slide on the surface. Naturally, this is at the bottom of the stairs. At what distance - the master himself will decide, but usually the length of the entire chain, that is, when laying the legs, the proper square of 60 cm is formed with each other. The legs are preferably "to shove", otherwise there is a risk that the staircase will rolling on a particularly slippery or wet coverage. Installation is over.

In order for the stepladder for a long time rejoiced by the owner, it can be given an external gloss, carefully sinking with small sandpaper and placing lacquer.

For storage, it is possible to impregnate it with spent engine oil so that the staircase intended for garden works all winter stood intact neither mold nor fungus.

Additional amenities

Scheme assembling wooden stepladder.

In order for working with the use of a stepladder to be comfortable, you can make an additional structural details of a wooden staircase. For example, several hooks nailed to the ends of the long elements will allow you to keep the bucket in your hands, and hang it around, thereby freeing yourself from gravity and increasing the speed of work.

Next, you can make a wide step to put this bucket or get up with both legs, getting to particularly high places. Then the pen must be attached to the stepladder for greater security.

Errors in the manufacture of a stepladder

- To prevent skew when inserting stairs into the holes, you should drill them in parallel with the other side. That is, the work should be done immediately on both elements. To do this, use long drills.

- When installing nuts, it is impossible to forget about the washers, they will help ease mounting and make a tightening stronger. If the holes are made large, then the bolt's hat does not stick inside, but will remain on the surface, and the gain of the tightening can be varied.

- Neglect the adjustment of the spokes is also impossible: tightened on two sides with nuts, they will not fall out the steps from their own grooves. If I could not get the factory studs, you can cut the thread on any steel elements.

- Can be used instead of a metal circuit of the head cord. But the iron is stronger, and the cord at the enhanced load will be bored.

- It is necessary to wear rubber knobs on the legs, even if the stepladder is reliably composed with a chain. You can apply traffic jams from anything or wrap non-standard ends with several layers of tape tissue. Then you can be sure that the stirring with an iron chain will not slip into the most responsible moment.

Article on the topic: how to make a reliable aviary for a dog do it yourself

Thus, applying all the right actions, the wooden lap of its own manufacture can be used on any type of height-related: activity in the garden, repair in the apartment, even for screwing the light bulb, the staircase will be as impossible by the way. The model provided by the manufacturer cause some complaints due to the ease of aluminum profiles, of which it is made, and the wooden will be much more reliable and more stable.