So as not to knock your teeth in a cold apartment or private

House, you need to think in a timely manner.

The first and most weighty source of heat loss in homes is the walls. But, if in a country house, in the country or in the garage, the insulation is most often solved in favor of outdoor performance, then in the apartment, especially if it is facade and located in the areas of the city, where it is forbidden to change the architectural appearance of the building, preference is given

Inner warming.

Hansard insulation is also possible only from the inside. Although, in fairness, it should be noted that the insulation of the walls of the foam inside the apartment requires further repair and finishing works.

In addition to foamflast, for internal insulation can be

Used: mineral wool, expanded polystyrene or even spraying polyurethane

foam. However, most owners prefer precisely foam. Why

Is this thermal insulation material?

Advantages of insulation of foam from the inside:

- low cost;

- non-toxicity. This parameter is especially important because

The inner insulation of the walls of the walls of the foam is performed;

- Simple, intuitive technology for performing work;

- the opportunity to warm up with their own hands;

- Excellent thermal insulation properties of foam (coefficient

thermal conductivity 0.038 W / m ° C).

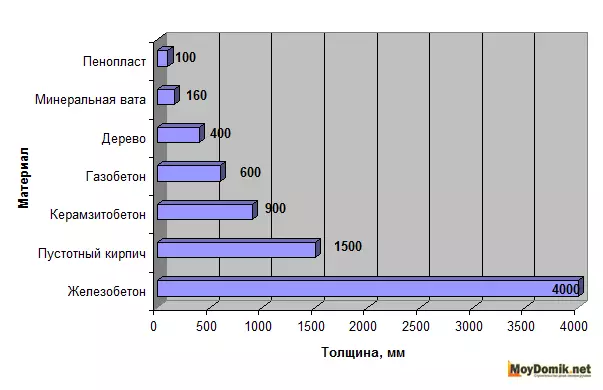

It is better to illustrate this indicator by an example. For

obtaining the same result you need to use 100 mm foam and 160 mm.

Mineral wool. Comparison with other materials is presented in the diagram.

Diagram - Comparison of thermal insulation properties of foam with other materials

The diagram shows that most effectively still, will

Use foam for insulation of walls from the inside.

Foam selection for wall insulation

Basic requirements taken into account when choosing foam

Such: density and required thickness. As for the density, then with more

It is easier to work with a dense material. He will not fly away in the form of balls by

All room.

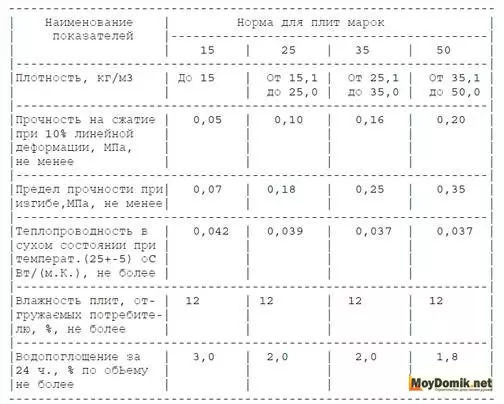

According to the norms of DSTU B.V..2.7-8-94 "Plates of polystyrene foam.

TU "Polyfoam is divided into four groups and has the labeling of the following order:

PSB-C 15, PSB-C 25, PSB-C 35 and PSB-C 50. The properties of each brand are indicated in

Table

Table - Polyfoam selection for wall insulation - marking and properties

PSB letters mean a method of manufacturing foam -

Pressure method. The properties of these brands are unchanged for a long period

time (up to 40 years).

Article on the topic: How to put the slopes with your own hands?

At the same time, many mistakenly believe that the numbers at the end

Markings indicate the actual material density. However, it is not. After all

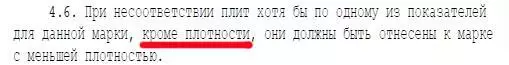

According to the Mentioned Dasta

Extract from DSTU about foam density

Therefore, in fact it turns out that the PSB-C -15 has a density of +/- 9 kg / m3. And PSB-C 50 - +/- 30 kg / m3. Take this in the calculation!

Tip:

For insulation of the walls you need to take a brand not lower than PSB-C 25.

The second point is the required thickness of the sheet. Many are asked

The question is which thickness of the foam to choose. The answer depends on a number of factors:

- Temperature regime in the region;

- The direction and strength of the wind;

- Wall material (brick, concrete, wooden);

- The expected increase in heat after insulation.

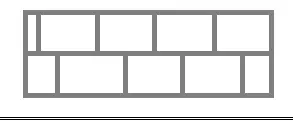

Tip: To improve the properties of foams should be purchased

Not one sheet with a thickness of 100 mm, and two 50 mm thick. and put their flashes

So that the shake of the first layer fell to the middle of the second layer sheet.

Instructions for the insulation of walls by foam from the inside

For work, you will need a building material and tool.Material:

- Styrofoam;

- Serpentine ribbon for sealing joints;

- polymer mesh;

- cement-based glue;

- umbrellas (special dowels for fastening foam);

- Universal primer;

Tool:

- Roller or painrol brush for primer and container for it;

- Perforator and drill;

- spatulas;

- sandpaper;

- Level, line and labeling pencil.

Provides work in several stages:

1. Pretending stage

The importance of this stage is difficult to overestimate. Because from quality

The basics depends and the quality of the clutch of the sheet with the wall and the ability of the foam save

its thermal insulation properties.

Before you get to work:

- Replace windows if necessary. Otherwise

The effectiveness of insulation will be reduced to zero;

- Clean the wall from wallpapers, clogged with nails, etc.;

- close all the cracks;

- Remove fungus. If it is not washed off, you need to consider it

emery paper;

- dismantle the plinth;

- Crop out floor covering on sheet thickness. Material

Mounted only on the bearing coating;

- Align possible irregularities wall. Otherwise

Between the sheets there will be air, which is fraught with displacement of the dew point.

Tip: To eliminate small defects, use putty,

To align the wall with transitions more than 10 mm - only plaster.

2. Preparatory stage

At this stage, the following steps:- Prepared Wall is processed by primer. From wide

Pitrate varieties give preference to a universal mixture

Verified manufacturer. For example, good reviews about Ceresit St-17. After it

Application on the wall is formed a thin film that will provide both bioprotechnics and

The best adhesion of the adhesive mixture with the wall;

Article on the topic: Zigzag pattern in the interior (12 photos)

Tip: Do not use the sprayer to apply primer.

So it is applied and dries unevenly, and this reduces its properties.

- The wall should dry. To do this, it is enough to provide

good air ventilation in the room;

- Marking is applied. As practice is evidenced, walls

Most apartments of the Soviet period building (Khrushchev and Panel Houses),

uneven. If you have the same, then draw the line, as close as possible to the floor.

On it you will even even. Then the subsequent ranks of the sheets will fall

relatively smooth Why relatively? Yes, because DSTU is provided

Deviation +/- 10 mm on a sheet of size of 1x1 m. At the bottom and on the sides, we embarrass

trimming foam. For the same reason, you do not need to do a large number

Billets and apply the drawing to the entire wall - only at an angle.

3. The main stage

Wall insulation by foam from the inside can be performed by two

ways:

- Frame method . This method is used if planned

Further trim plasterboard or clapboard. It is mainly due to

What the thickness of the received UD and the SD profiles are 27 mm. Polyfoam is stolen between

with them. And thickness of 27 mm. clearly little in order to perform high-quality

Wall insulation by foam inside the house. But, under the lining the skeleton method

Suitable as it is impossible. This is due to the fact that it is equipped for it

Wooden frame with a thickness of a bar of at least 50 mm.

- Frameless way . If planned wall decoration

putty.

How to insulate the walls of foam from the inside - sequence

Performances with a frameless way of insulation under putty or plaster

We proceed to the installation of foam on the wall. Work starts

bottom, from a remote angle.

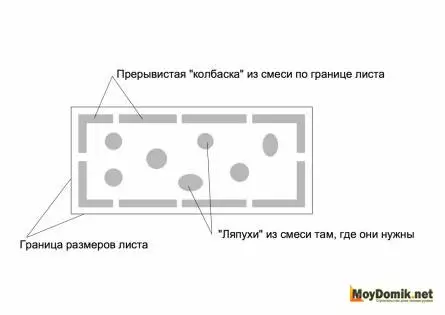

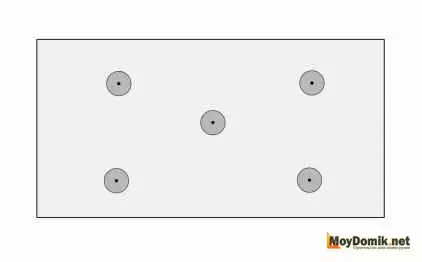

- A glue solution is applied to the sheet. The method of applying is shown

in the scheme;

Method for applying glue on foam

- The sheet is applied to the wall and the floor (if it is uneven, then

drawn strip) and pressed;

Applying foams to the wall and semi

Tip:

Davit is not much, otherwise the sheet is sold.

- A hole for a dowel-umbrella (fungus) is drilled in the center of the sheet;

- the umbrella is fixed by a sheet;

Tip: The umbrella hat should drown a little in the foam

Or be lonely with a sheet. Otherwise difficulties may arise with

Finish finish.

- For more reliable fixation in the corners of the sheet are also clogged

umbrellas.

Accessing umbrellas for reliable foam fixation

- If polystyrene polystyrene plates are smooth, you can perform

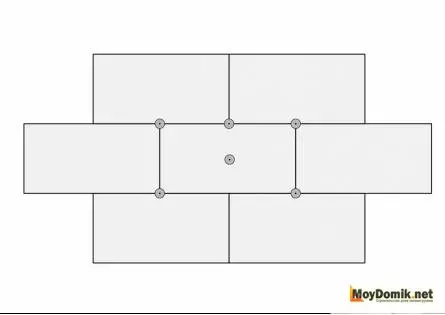

Installation according to such a scheme.

Article on the topic: Features of living room design with a TV on the wall

Foam mounting scheme

Such a device allows you to save on umbrellas, but

Makes the installation of a few "hlipping".

So that the insulation of the walls of the foam from the inside was more

Qualitative, the sheets of the second row are shifted. This installation scheme will ensure the absence

Perpendicular junctions.

Scheme of the displacement of foam sheets when mounting

- that the design does not miss the heat when the sheets is not

there must be cracks;

- To arrange the upper row you need to fit the sheets by

size. The foam cuts with a conventional hacksaw or a building knife (if its

The thickness does not exceed 50 mm);

- Sealing seams. Seams with a thickness of more than 10 mm need to be seen

trimming foam. Those that are less than 10 mm. you can blow foam;

Sealing seams foam

Tip:

To the piece kept tightly, on his back side

You need to apply foam.

- Sticker Sickle Ribbon. The tape is good because it has one

The side treated with glue. It is easy to glue. The price of ribbons is insignificant, in here

value is difficult to overestimate, because It protects the seam from the deformation. Without

The use of tapes on the seam will go cracks;

Tip:

Dipping joints are eliminated by a grater for foam.

- Melting of umbrella hats. Only those who are recessed in

Styrofoam. In principle, the hats "hide" and during the putty wall. But then

The subsequent mixture will be applied with a thick layer, and will dry longer.

4. Finishing stage

- Glue is applied to the top sheet surface. Layer width

equal to the width of the reinforcement grid.

- A grid is applied and hiding under the mixture layer.

- After the wall is completely dry, you can start

Decorative finish.

Tip: Try not to allow folds on the grid. They are bad

Disguised in the future.

Folds on the grid

Wall insulation from the inside by foam - video

In conclusion, I would like to note, on what should not save when

internal insulation foam:

- on ventilation. To do this, do in the windows

Special holes. Metalplastic windows are equipped with them by default, and

Here in the wooden frames of the holes are not provided. Ventilation is needed in order

To avoid condensate.

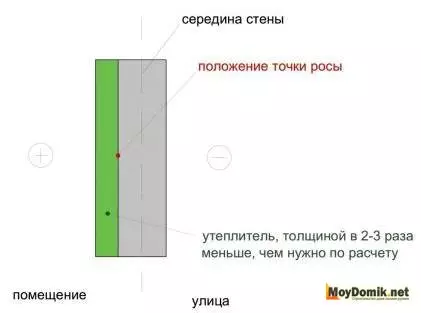

- On the thickness of the insulation. The picture shows how to shifts

Dew point.

Displacement point dew - scheme

- on the density of the insulation. Low density insulation not

Allows you to get the planned effect from the insulation of the walls of the foam from the inside.

Foam density - factor

- on the quality of the primer. Poor-quality primer will not protect

You from the appearance of mold and the development of fungi.

Education fungus and mold on the walls

To note, insulation of foam of balconies and loggia has

Its specifics with which you need to get acquainted additionally.