Most often to our homes, sites, the garages are connected with a single-phase network of 220 V. Therefore, the equipment and all the homemakes make it so that they work from this power source. In this article, we consider how it is virtially making a single-phase engine connection.

Asynchronous or collector: how to distinguish

In general, it is possible to distinguish the type of engine on the plate - the nameplate - on which its data and type are written. But this is only if it was not repaired. After all, under the casing can be anything. So if you are not sure, it is better to determine the type on your own.

So looks like a new single phase condenser engine

How the collector engines are arranged

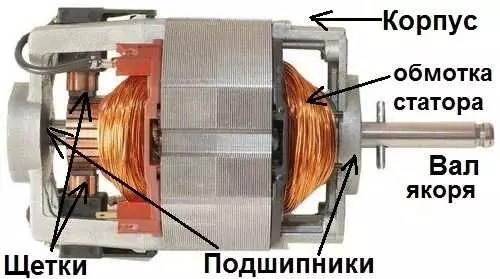

You can distinguish asynchronous and collector engines in structure. The collectors necessarily have brushes. They are located near the collector. Another mandatory attribute of the engine of this type is the presence of a copper drum separated by section.

Such engines are available only single-phase, they are often installed in household appliances, as they allow you to get a large number of revolutions at the start and after overclocking. They are also convenient because it is easily allowed to change the direction of rotation - it is only necessary to change the polarity. It is easy to organize a change in the speed of rotation - by changing the amplitude of the supply voltage or the corner of its cut-off. Therefore, similar engines are used in most of the household and construction equipment.

Building collector engine

Disadvantages of beeter engines - high noise of work on large revs. Remember the drill, a grinder, a vacuum cleaner, a washing machine, etc .. noise with their work is decent. On small revolutions, collector engines are not so noisy (washing machine), but not all tools work in this mode.

The second unpleasant moment is the presence of brushes and constant friction leads to the need for regular maintenance. If the current collector does not clean, contamination with graphite (from erasing brushes) can lead to the fact that the adjacent sections in the drum will be connected, the motor is simply stopped working.

Article on the topic: A black screed of the floor on the ground with their own hands

Asynchronous

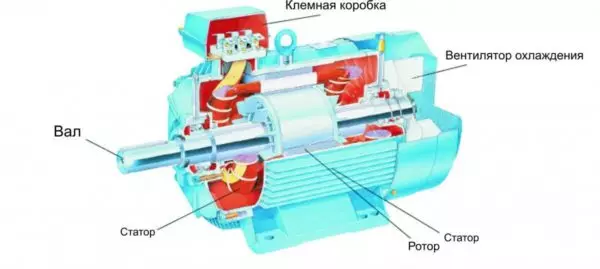

The asynchronous motor has a starter and a rotor, may be one and three phase. This article discusses the connection of single-phase engines, but it will only be discussed about them.

Asynchronous motors are distinguished by a low level of noise when working, because they are installed in the technique, the noise of operation is critical. This is air conditioners, split systems, refrigerators.

The structure of an asynchronous engine

There are two types of single-phase asynchronous engines - bifilar (with launcheling) and condenser. The whole difference is that in bifilar single-phase engines, the launcher works only before overclocking the motor. After it turns off with a special device - a centrifugal switch or a power-proof relay (in refrigerators). It is necessary, since after overclocking it only reduces the efficiency.

In condenser single-phase engines, the condenser winding works all the time. Two windings are the main and auxiliary - shifted relative to each other by 90 °. Due to this, you can change the direction of rotation. The capacitor on such engines is usually attached to the case and it is easy to identify it on this basis.

You can more accurately determine the bifolar or condenser engine in front of you using the windings measurements. If the resistance of the auxiliary winding is less than 2 times (the difference can be even more significant), most likely, this is a bifolar engine and this auxiliary winding is starting, which means that a switch or starter relay must be present in the circuit. In condenser engines, both windings are constantly in operation and connecting a single-phase engine is possible through the normal button, toggle switch, automatic.

Schemes for connecting single-phase asynchronous engines

With launcher

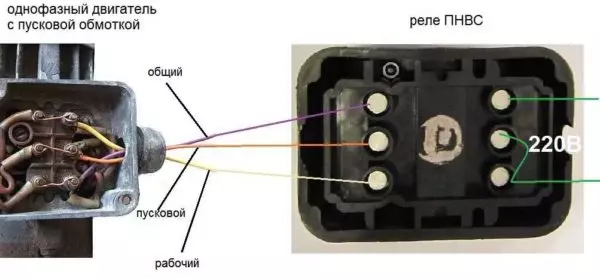

To connect the engine with a starting winding, you will need a button with which one of the contacts after switching is swapped. These opening contacts will need to be connected to the launcher. In stores there is such a button - this is PNVS. It has medium contact for the time of retaining, and the two extremes remain in a closed state.

The appearance of the PNVS button and the contact status after the "Start" button is released "

Article on the topic: Quad bike do it yourself

First, with the help of measurements, we determine which winding worker, which is starting. Usually, the output from the motor has three or four wires.

Consider the option with three wires. In this case, the two windings are already merged, that is, one of the wires is common. We take the tester, measure the resistance between all three pairs. The working has the least resistance, the average value is a starting winding, and the largest is a common output (the resistance of two sequentially turned on the windings is measured).

If there are four conclusions, they will be called pairwise. Find two pairs. The one in which the resistance is less - a working, in which more is launched. After that, connect one wire from the launcher and operating winding, output the shared wire. Total there are three wires (as in the first version):

- One with a working winding - a worker;

- from the launcher;

- Common.

With these three wires and work further - we use to connect a single-phase engine.

With all these

- Connecting a single-phase motor with a starting winding through the PNVS button

Connecting a single-phase engine

All three wires connect to the button. It also has three contacts. Required start-up wire "Sing on average contact (which closes only at the start time), The rest are two - on the edgeIe (arbitrarily). Connect the power cable (from 220 V) to extreme input contacts of the PNVS (from 220 V), the average contact with the jumper with the worker (pay attention! Not with common). Here is the whole single-phase motor inclusion scheme with a starting winding (bifolar) via button.

Condenser

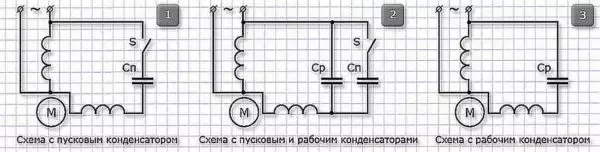

When connecting a single-phase condenser engine, there are options: there are three connection schemes and all with condensers. Without them, the motor is buzzing, but does not start (if you connect it according to the scheme described above).

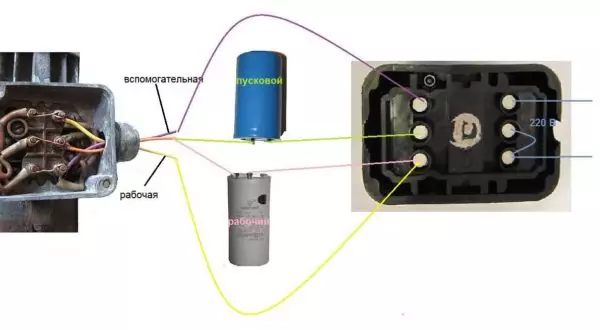

Schemes for connecting a single-phase condenser engine

The first scheme - with the capacitor in the power supply circuit of the starting winding, are well started, but when the power is fine, the power is far from the nominal, but much lower. The inclusion circuit with the capacitor in the operating winding circuit gives the opposite effect: not very good indicators when starting, but good performance. Accordingly, the first scheme is used in heavy launching devices (concrete mixers, for example), and with a working condenser - if good performance is needed.

Scheme with two capacitors

There is another third option to connect a single-phase engine (asynchronous) - install both capacitors. It turns out something average between the options described above. This scheme is most often implemented. It in the figure is higher in the middle or in the photo below in more detail. When organizing this scheme, the PNVS type button is also needed, which will connect the capacitor only not the start time until the motor is "releasing." Then two windings will remain connected, and the auxiliary through the condenser.

Connecting a single-phase engine: a diagram with two capacitors - working and starting

When implementing other schemes - with one condenser - you will need a regular button, automatic or toggle switch. There everything is connected simply.

Selection of condensers

There is a rather complicated formula for which the required capacity can be calculated accurately, but it is quite possible to do with the recommendations that are derived on the basis of many experiments:- The working capacitor is taken at the rate of 0.7-0.8 μF per 1 kW of engine power;

- Starting - 2-3 times more.

The operating voltage of these capacitors must be 1.5 times higher than the voltage of the network, that is, for the network 220 in we take a capacity with an operating voltage of 330 V and above. And so that the start is easier, in the starting chain, look for a capacitor a special condenser. They have the words Start or Starting in the marking, but you can take the usual.

Changing the direction of motion of the motor

If after connecting the motor works, but the shaft is not spinning in the direction you need, you can change this direction. This makes changing the winding of the auxiliary winding. When the scheme was collected, one of the wires filed a button, the second was connected to the wire from the working winding and brought the overall. Here it is necessary to cross the conductors.

How can everything look in practice

Article on the topic: Warm resistance: how to check the thermostat and sensor