Overlapping between floors, basements or attic

Constructively arranged in two schemes - Bearless overlap (based on

It is using a monolithic plate), and the beam overlap (apply

Wooden beams overlap). Make overlap for the separation of inter-storey

Premises, as well as to separate the rooms from the basement and the attic. Beams can

be made of various materials, such as wood, monolithic

reinforced concrete or metal runs.

Wooden beam overlap

Wooden beam overlap

Installing wooden beams of overlapping allows you to solve such tasks:- achieve the necessary indicators of the strength and hardness of the overlap;

- ensure the conformity of sound insulation and heat transfer resistance to the level required for energy saving;

- To withstand compliance with the established standards for pair and breathing performance.

Selection of beams for inter-storey floors:

By type and type:

- Broqa overlap from timber . Most often for the manufacture of beams

Choose a rectangular segment. The height of the timber must be within

140-240 mm, and thickness 50-160 mm. It is withstanding the rule: the thickness of the beam

It is at least 1/24 from its length. Professionals celebrate that big

The strength is inherent in a wooden beam with the aspect ratio of 7: 5.

- Blocks overlap from log . Economically more profitable

decision. Log has a lot of resistance to loads, but also low resistance

To bend. Log suitable for use only if it is sustained in dry

conditions for at least one year.

- Overlapping beams from boards . Using the board leads to

A decrease in the number of sawn timber consumed for the device.

But it is worth noting that in this case the stability of the overlap to

Fire, durability and sound insulation. Usually the board is used when

Construction of the attic overlap. To enhance the boards you can use

reception - combat together two boards in length. Then the total cross section will

Calculate the level of load. This design can withstand the load in

2 times big, rather than a bar or two boards laid close to each other. IN

This case is carried out by self-drawing or nails,

recorded in a checker manner in 20 cm increments.

Article on the topic: Homemade simulator Hyperextension (drawings, photos, video)

Recommended! A detailed description of wooden beams overlap - types, species, calculation of bending beams, strength and load.

Wooden overlap beam section

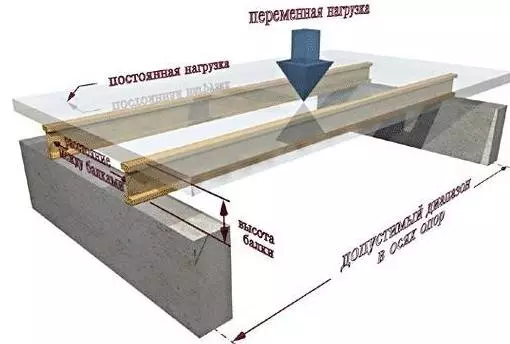

Directly depends on the magnitude of the intended load on the beams. The load is divided into a constant, created by floors, furniture, and a variable depends on the number of people and items at the overlap.Wood floor beam mounting method

Installation of solid wooden beams Laying whole wooden beams.

In this case, the beams are stacked without splicing. To minimize the deflection, you need to lay them along a shorter wall. Thus, the number of beams will increase, but the length of each individual beam will decrease.

Installation of reinforced (scrambled) beams Laying reinforced (designed) beams.

This method of installation involves the installation of the junction on the inner wall of the building.

Laying beams short runs Laying short runs.

On the jargon of builders they are called exchangers. In essence, these are beams laid perpendicular to longitudinal beams. Serve to enhance the overlap.

Scheme laying beams short runs

Material prepared for site www.moydomik.net

It should be noted that the flooring device on wooden

The beams will be reliable under the condition of the proper selection of wood. So, N.

Large breeds are suitable for this type of work. The reason for this is bad

Bending resistance, but the wood of coniferous rocks is perfect.

The main thing is that it be cleaned of the crust and processed by antiseptic solution.

Pluses of wooden beams overlap:

- Low weight. This allows you to reduce the load on the walls and the foundationat home, simplify transportation and facilitate the installation process;

- the ability to perform work together, with your own hands, without

attracting special equipment;

- availability and relatively low cost;

- the ability to lay insulation;

- High speed of work.

Cons of wooden beam overlap:

- Restrictions on the length of the closed span. Wooden length

The beams does not exceed 6,000 mm, and they can close a maximum of 4,500 mm. without

Installation of additional vertical support;

- The need for additional protection of wood from rotting,

biological destruction and splits;

- Puzzle. Wooden beam can "play" when moving

It is people and create additional noise. Requires an additional device

Soundproofing.

Article on the topic: How to calculate the number of self-tapping screws for attaching plasterboard?

Installation of wooden beam overlap

The technology of the ceiling device for beams provides

Performing work in several stages:

1. Calculation of the cross section (diameter) of the wooden beam overlap with

Taking into account the requirements of SNiP 2.01.07-85 "Loads and Impact".

The estimated indicator of the maximum permissible load on

1.m.kv. Amount:

- For basement and inter overlap - no more than 210

kg;

- For attic - no more than 105 kg.

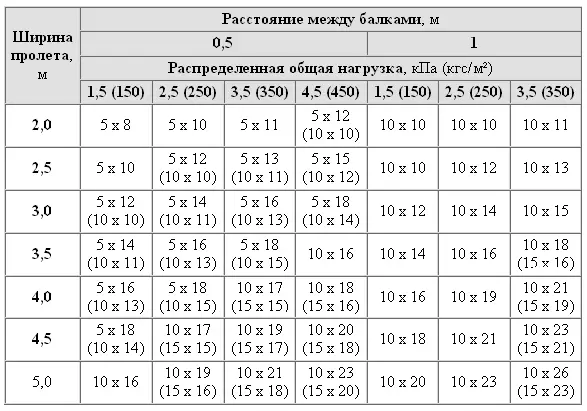

In more detail, the cross section is calculated with the distance

Between the beams (see the section Table of overlap beam).

Overlapping Ball Single Table

Holding the length of the beam is important to remember that the wood is prone to bending.

Calculation of the deflection of a wooden beam

- For basement and interlated overlap minimum

The deflection cannot exceed 1/300 of its length. Those., The beam is 3,000 mm long. can not

Fake more than 10 mm. In the most remote area;

- For an attic - no more than 1/200.

Clear the deflection can be removed by beam beam. Building

The rise is so called this process - allows you to compensate for deformation.

Roughly speaking, the beam should be slightly curved inwards to tailored to bend

Take a proper look.

If necessary, an amplification of wood beams is performed.

2. Acquisition of timber, logs or lumber and processing

Its antiseptic, fire, antifungal solution and biological

Protection.

3. Selecting the type of beam mounting to the wall.

Fastening wooden beams overlap to the bearing wall

carried out in two ways:

- Fastening in the wall. The beam is inserted into the bearing wall at a depth of 150-200 mm.

Fastening wooden beams overlap to the bearing wall

With this method of installation, the end of the beam need to be cut at an angle of 60 °. To protect the ends of the beams, they need to overtake in two or three layers of rubberoid. At the same time, the end of the beam remains open, and he should not rest in the wall. The presence of a gap in 20-25 mm. Allows you to provide free air exchange. And the resulting niche (gap) is filled with mineral wool.

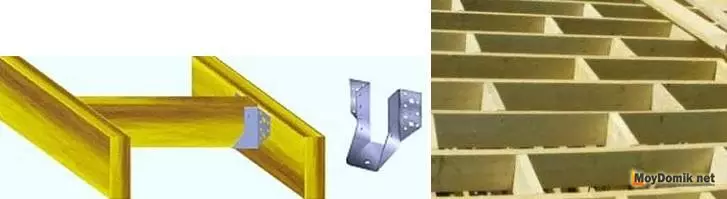

- Mounting suspended method. In this case, the beams are fixed

on the wall through metal linings.

Article on the topic: How to sew a braid for Roman Curtain: Masters Recommendations (2500)

Fastening wooden beam overlap suspended method

4. Laying wooden beam overlap

At this stage, the beams of the desired length are prepared. Length

Depends on the installation method. If the beam starts into the wall, then calculated

So: room length plus 300-400 mm. For mounting in the wall. If attached to K.

Wall, then the length of the beam is equal to the length of the room.

Installation of wooden beams overlap starts with extreme

Baok. Each beam is checked by a construction level. After that beam

Fixed in wall nests using dry rubble.

Next, intermediate beams are installed. For this

It is advisable to pull the fishing line between the extreme beams and put it

rest. The distance between adjacent beams should be the same.

When the beams are installed exactly by level and verified

Their horizontal can be concreted in the landing jacks.

Conclusion

Made by such technology overlapping with wooden beams

For several decades to serve you to serve you. However, to extend the term

his services, you need to handle wood and produce a periodic inspection for

Control of their condition. If there are defects, perform repairs (partial or

Full replacement of damaged elements).