Gas column device

A gas column is a rather difficult device, which, with proper care and compliance, the rules of operation can serve for a long time. But sooner or later, those or other malfunctions of the gas column can occur. Especially if you take into account the quality of gas and water, submitted by utility services to apartments and at home.

Choosing a gas column, you need to familiarize yourself with the difference in models that may differ not only by appearance, but also with power when water heating.

In accordance with the rules of security, the breakdown of gas devices should be trusted only by professional gas producers, but to know about some common causes, due to which the gas column does not function as needed.

Knowing some subtleties, it is possible to determine the cause of the problem before the arrival of specialists, and in some cases it is possible to repair the gas column.

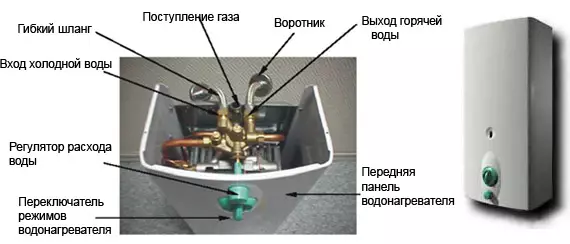

What are the faults of the gas speakers? To begin, it is necessary to know how the gas column is arranged, the repair will be dependent in many respects. Here are the general principles of its work.

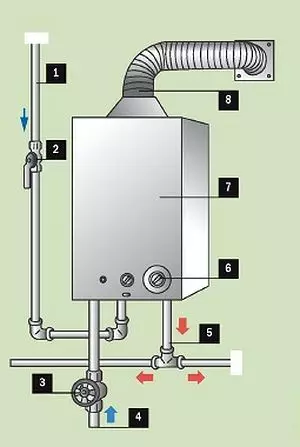

Scheme of connecting the gas column to engineering communications: 1 - gas pipe; 2 - gas valve; 3 - plumbing valve; 4 - Cold Water Pipe; 5 - pipe with hot water; 6 - column controls; 7 - column body; 8 - chimney pipe.

The operation of the gas column consists in heating the tap water with gas. To accelerate the heating, the heat exchanger serves, in it the flow of water is distributed over thin tubes that are directly above the gas burner. Due to this, it turns out to heat the water quickly enough, directly in the process of use, to accumulate the heated water in advance in the tank is not necessary.

This is the main device of the gas column, the remaining filling is designed to adjust the heating of water, ensuring safety, gas ignition. Sorry of the main burner happens:

- Piezorozhig without a stamp;

- From the stobble. The constantly burning stall turns on with a piezorozhig (manual or automatic from the button) or lights from the match manually (in the old Soviet speakers);

- Electronic ignition. According to its principle and the device, it is similar to the ignition of the car.

Almost any column is equipped with an elementary device - mechanical bond between the valve in the gas pipe and the membrane in the water intake device. The gas valve is opened only if the water pressure presses on the membrane with sufficient force. The principle is simple: there is no water - the gas is not served to the burner, the water turns on - the burner turns on.

Gas column does not ignite

The most common reason that the gas column does not ignite, may simply become the absence of thrust in the ventilation well. It is possible that the chimney over time is simply clogged with soot or a foreign object fell into it. In this case, the protection system that is inside the column is triggered, and the gas overlaps automatically directly in the instrument.

Article on the topic: How to make shelves for walls with their own hands - 60 photos of ideas

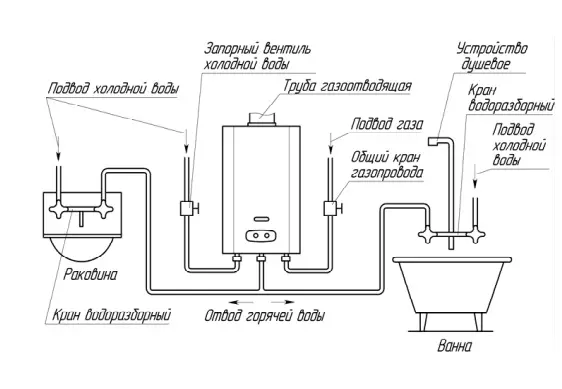

Scheme of installation of the gas column.

Check the chimney cravings. This is done quite simple: a burning match must be reduced to the well, if the flame is deviated in his direction, it means that there is a traction, everything is fine.

It is enough to eliminate the cause, and the gas column will again work regularly. Well, you can read yourself or cause masters.

Another reason for the malfunction of the gas columns in this case may be a simple discharge of batteries, but this concerns exclusively instruments with automatic ignition (from batteries or generators). Despite the assurances of manufacturers, arguing that the battery life is 1 year, it should be replaced much more often.

Debugg:

- Check the power on and off keys of the gas column;

- Replace batteries.

Thirdly, the gas column does not ignite simply due to insufficient water pressure. Check it easily - just need to open the crane of cold water. If a small pressure is quite possible that the reason lies not in the column, but in the water regime itself or in its separate area.

If the pressure in the Cold Water Tap is stronger than in the hot crane, then, perhaps, the reason lies in the waterstorm of the gas column (the membrane was deformed or filters clogged). Quite often, the asges installed additionally coarse filters are becoming.

Debugg:

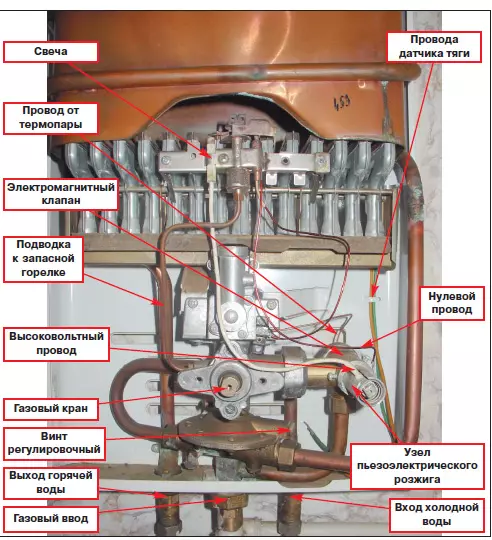

Scheme of the gas column device.

- First you need to call the utilities to find out the cause of the absence of pressure;

- Rinse cleaning filters or replace such in the mixer;

- In the communal service, you can leave an application for cleaning pipes supplying hot water;

- washing the gas column from the soot and from combustion products;

- Replace the diaphragm of the water node column.

Fourth, often happens when the gas column is lit and goes away immediately. In this situation, it is necessary to adjust the flow of water (cold and hot).

Please note: in no case is it in any way to dilute the cold water, it leads to an immediate flame extract, and similar actions violate the rules of operating the column.

Troubleshooting: It is necessary to reduce the flow of water from a cold crane.

Another reason for the lamination of the burner may be the wear of the water membrane. Over time, the membrane from permanent loads is deformed, when the water is supplied, the burner turning device loses sensitivity and does not work. It is impossible to do anything about it, even in the columns of serious imported producers of the membrane should be changed every 5-7 years.

Open the water crane at the maximum if the column is turned on with the maximum pressure, it means that it is just in the membrane, it will have to be replaced.

Column goes out in the process of work

Scheme of the gas column.

If the column is turned on, but it goes out, then, most likely, the cause is a bimetallic temperature sensor designed to prevent the column overheating. The fault, as a rule, has 2 manifestations:

The burner lights up, the column works normally for a while, after that it goes out and no time works. Attempts by ignition do not give results. After 15-20 minutes, the column can be turned on again, the burner lights up, then after about the same time interval goes out again. This happens due to the increased sensitivity of the sensor.

Article on the topic: Papers with your hands from fabric with patterns: mittens and butterfly, original schemes, knitted mittens, cross-stitch, heartfelt hearter for kitchen, photo gallery, video instruction

This case is usually warranty. But the fact is that this is a seasonal problem, and mainly it occurs in winter, when the windows in the kitchen are constantly closed, or during the summer heat. In both cases, the air temperature is increased, and the column is properly cooled. It may happen that the problem will show itself when the warranty period will expire. Then the repair will have to be at your own expense.

Turning off the column is chaotic character, the device does not light up sometimes at all. Such a heater behavior may occur due to wear of the sensor conductor isolation. A closure occurs on the body, leading to what the safety valve is triggered. The gas driver is useless - the problem is not on the gas part. Do not finish yourself too. It is advisable to refer to the service center or to the manufacturer of this model.

Weak water pressure

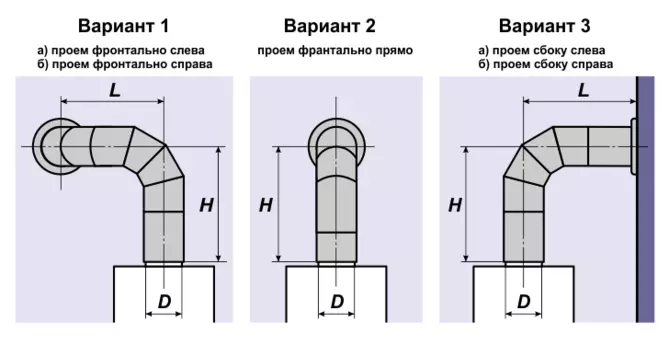

The scheme of the chimney of the gas column.

If the gas supply occurs, therefore, in the water supply device, the water pressure is normal, the problem lies in the heat exchanger zado. One of the reasons may be idling the stobnant for a long time. The reserve time to heat the heat exchanger, thereby causing intensive evaporation of water residues. The accumulated scale is not washed out due to the lack of water current and have time to grab until the next turn on the column. As a result, the column does not work.

Figure tubes skidding may occur because of tough water. At water temperature, more than 80 ° C is deposition of scale, and at 82 ° C, this process begins to go more intensively. In order to avoid increments of scale, you should not use too hot water. Repair is to replace or clean the heat exchanger.

Washing heat exchanger with certain skills can be made independently. This will require:

Scheme of the gas column device.

- a set of horn keys;

- Cross and flat screwdriver;

- rubber hose;

- Set of paronit pads;

- Antinequipine or acetic essence;

- Tazik or plastic bucket.

First, remove the accessories from the column, and then the casing. After that, at the entrance you should block the water supply and closer to the column to open any of the heated water cranes. Then unscrew the feed tube from the heat exchanger and take to the side. After unscrew the nut from the heat exchanger, water from the heat exchanger will go away. It is necessary to merge near the liter.

After that, on the heat exchanger input, put on the hose, lift it slightly above the columns, insert the funnel into the hose and pour the cooked solution into it with a thin flowing. It is necessary to pour slowly, otherwise the antnakipin will push back. The solution in the heat exchanger must be left for a couple of hours. In order for the reaction to pass faster and it took less time, the substance can be warmed on a burning stall.

Submold a plastic bucket or basin for the crane and open the water supply slowly into the gas column. Pay attention to what will come out of the hose. If there is a lot of sludge and the head after washing will be quite good, it means that everything turned out, if not, then the procedure must be repeated again. When using Anticpine, this is not required.

Article on the topic: Nutrition curtains in the interior - advantage and photos

The column is accompanied by cotton

Cotton and microzers accompanying the inclusion of the column may occur for the following reasons:- Too strong gas pressure, the burner lights up too actively, due to this, the flame breaks;

- The gas is too weak, the air is inside the burner, which is accompanied by a microcus;

- Due to insufficient thrust in the ventilation channel or well, due to a possible zero of the gibber or other elements of the column, due to the discharge of the gas column ignition batteries.

Debugg:

- call to the communal service;

- replacement of batteries;

- cleaner cleaner;

- Call chopper.

In other cases, it is better to call a specialist to eliminate faults.

Gas column ignites but warm water badly

Causes can be different. Insufficient water heating happens due to low column power. To clarify, simply carefully read the passport of the installed device, read the technical specifications, etc. At the same time, do not open the hot tap in the bath, in the kitchen and sink or purchase the unit more powerful.

Water may not be warm enough because of the ordinary burner blocking, the evidence of which can be the yellow color of the flame and the appearance under the column in the process of its sage work. Water will also be heated enough in the case of low pressure supplied gas.

Troubleshooting:

- self-cleaning column or wizard call;

- adjustment of the crane on the supply of hot water;

- Call to gas service.

Fits the smell of gas when the column is turned on

It is very serious, and he should not be keen on it. Remember: when you turn on the gas smell column should not be! Immediately turn off the gas supply column and the factor of the gas supply, ensure constant ventilation indoors, call the emergency service (by calling 104) and wait for the brigade. In no case, the repair of the gas column does not hold their own hands.No gaze

When the gas column is turned on, a characteristic sound must be present. If the column simply does not want to heal, you need to listen to to understand whether gas is entered. If you do not hear such a sound, therefore, the gas does not arrive at all.

Troubleshooting: Call to gas economy or communal service to find out if any repair work is not carried out on the site. If they are not conducted, you need to call the gas engineer.

Leak water in the gas column

Sometimes in the compounds of the gas column it happens. Water compounds in the device are performed using precipitated nuts with sealing rubber gaskets. Over time, these gaskets lose their elasticity, become solid, and, therefore, water flows.

To repair the gas column, it is necessary to replace the rubber gasket. To do this, you should unscrew the cape nut, remove the worn gasket and install a new one. Sometimes there is a little single gasket, the nut is spinning until it stops, and the water will still feel. Then it is necessary to put an additional gasket.

Here are the main faults in the gas columns. However, if you are not confident in your abilities or there are no suitable tools for self-repair of the gas column, then it is better to turn to professional masters with this question.