Plates of overlap are designed to separate the building at levels (floors). If the plates are located between the floors, then this is the overlap, if above the last floor, then the coating. The difference lies only in the bearing ability. Increased requirements for strength and reliability are presented to these building structures, as they are the main carrier elements and perceive the load from the entire floor, including floors, partitions, equipment, furniture and temporary loads.

Plates of overlappings can be:

- Depending on the material: reinforced concrete, concrete, wooden, metal, combined;

- from the method of execution of prefabricated or monolithic;

One or another type of ceiling slabs is used depending on the design feature of the building, the maximum load on the overlap and installation method. Then we will analyze how to make the overlap with their own hands.

Example of calculating the monolithic slab

Before proceeding to the manufacture of the stove, it is advisable to make it calculation. Then an example of the calculation of the plane of the interleaved overlap to the deflection will be performed.Source data for calculation

The size of the building with monolithic overlapping take the size of 6x6 m divided into the center of the inner walls (span 3m). The overlap thickness will take 160 mm, while the working height of the overlap cross section will be 13 cm. Class B20 concrete (Rb = 117kg / cm2, RBTn = 14.3kg / cm2, Eb = 3.1 * 10 ^ 5 kg / cm2) will be used for the manufacture of the plate. Steel fittings A-500C (RS = 4500kg / cm2, Ea = 2.0 * 10 ^ 6 kg / cm2).

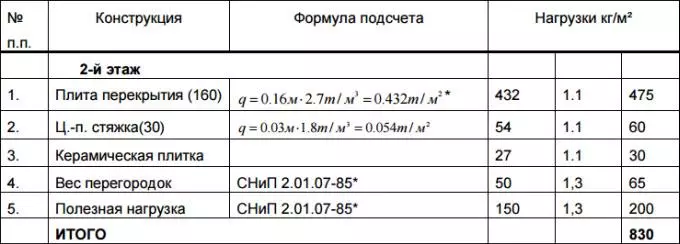

Overlapping load

The overlapping load will consist of weight: overlap slabs (in our cases 160 mm), a cement screed with a thickness of 30 mm, ceramic tiles, normative weight of partitions and payloads. All data are reduced in the table below with the coefficients.

Calculation of slabs for deformations for deflection

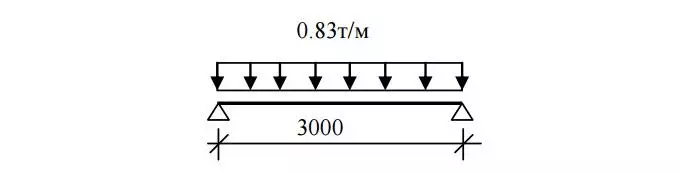

Overlapping scheme:

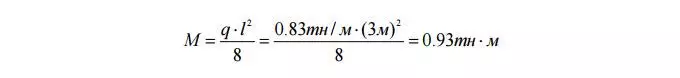

Now we need to choose the cross section of the reinforcement, for this we will define the maximum moment:

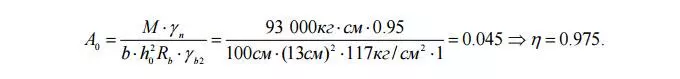

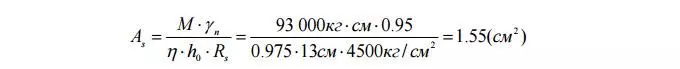

and the coefficient of AO with the width of the plate of the plate B = 1 (M):

The required area of reinforcement cross sections will be equal to:

Therefore, for the reinforcement of the 1store meter, the ceiling slab can be applied with 5 rods with a diameter of 8 mm in a step of 200 mm. The area of the armature cross section will be as = 2.51cm2.

We approached tight to the calculation of plates on deformations for deflection. From the source data, we know that the permanent load on the overlap is 0.63t / m² and

Temporary load on the overlap is equal to 0.2st / m².

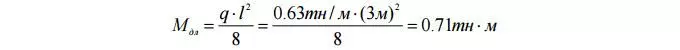

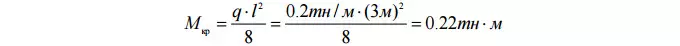

Calculate the maximum moment of the long-term load:

And the maximum moment of the short-term load:

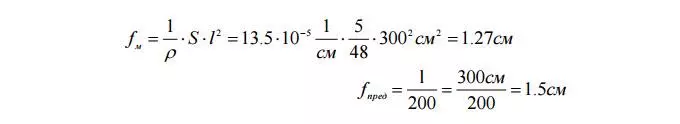

We find a coefficient that takes into account the type of load and the loading scheme S = 5/48 - for beams with a constant uniformly distributed load (Table 31, "Guide

According to the design of concrete and reinforced concrete structures from heavy concrete "). y '= y = 0 (Table 29 "Guide to the design of concrete and reinforced concrete structures from heavy concrete").

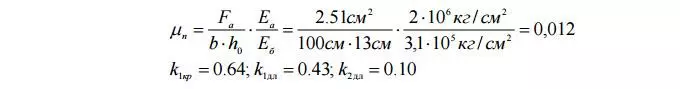

Coefficient for determining: k1kr; k1l; k2l.

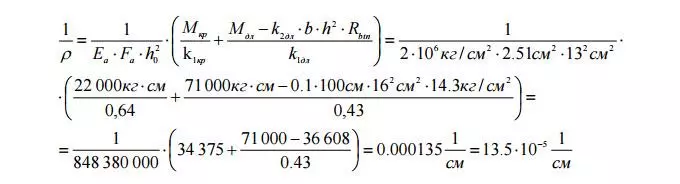

We consider the curvature of the axis with the simultaneous action of short-term, long and permanent loads:

Now it remains to determine the maximum deflection in the middle of the span:

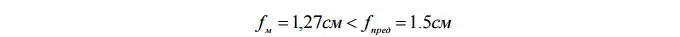

The condition is performed, it means that we adopted by the reinforcement Ø8 A-500c in a step of 200 mm is true!

Monolithic plates overlap for garage

Even building structures such as slabs can be made with their own hands. Let's look at the operating device for the garage. We will block the span with a long 4300 mm, so the plates will be manufactured 4500 mm. On each side, the stove will rely on the brick wall of 100 mm.Materials for the manufacture of plates

How to make slabs overlaid with your own hands? For the manufacture of the stove we will need:

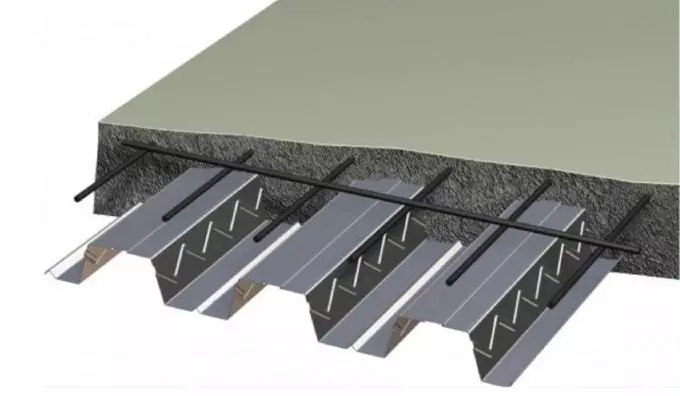

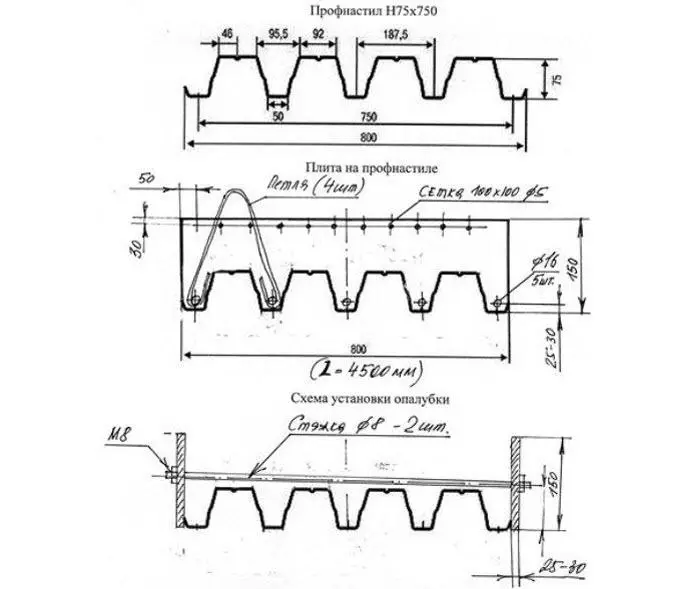

- Professional flooring H75 / 750 x 4500 mm, it will be used as a removable formwork;

- Wooden boards with a height of 150 mm and a thickness of 25 - 30 mm;

- Armature with a diameter of 16 mm;

- Mesh with a cell 100x100 with a diameter of 5 mm;

- screed with a diameter of 8 mm, 2 pieces per plate;

- Class B20 concrete.

Process manufacturing plate with your own hands

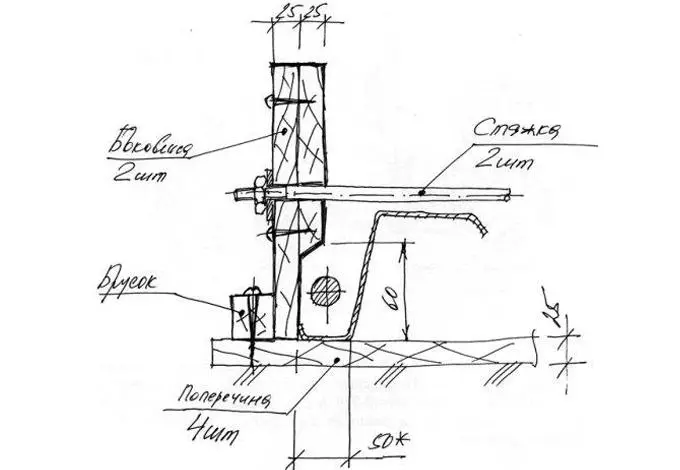

The sheet of professional flooring is stacked by a tough basis. Under the sheet you need to put crossbars (wooden boards, 4 pieces). We arrange formwork from the boards around the perimeter of the sheet.

We put the reinforcement in each sheet tray (5 pcs). The protective layer of concrete must be 25-30 mm. To the same revenue of reinforcement reinforcement (4 pcs) for transporting the plate (in our case, lifting it to the height of the overlap level of the garage). In the top of the slab, we laid the grid, which should also be protected by a layer of concrete 30 mm.

Article on the topic: Curtains selection ideas to window sill on windows

In order for the sheet of professional flooring well behind the concrete, it needs to be lubricated with oil (throughout) or to coat with a polyethylene film. Consumption of concrete on one plate will be 0.4 m3. Concrete is prepared in the gravitational concrete mixer, poured and the vibrator is stuck. You can remove the plate only after 7 days when concrete drops 70% strength.

Also possible overlap device directly on the walls. Sheets of professional flooring are stacked, reinforcement is performed and formwork is satisfied. Concrete rises in a crane in Badier and fills in a solid layer. Under the overlap you need to install backups at the time of the set of concrete strength. This method will be more costly, so the sheets of professional flooring remain in the overlap.

How much does it cost to make a slab overlap?

Now we calculate the cost of manufacturing plates with a total area of 29 m2 and a height of 150 mm. Costs for concrete - $ 335, price of professional flooring H75 - $ 400, reinforcement - $ 235, Crane services $ 135. As a result, we get the amount of $ 970. Such a cost will be whether to produce a slab right on the garage, that is, the profession remains under concrete overlap.If the slabs of overlapping do it with their own hands on Earth, the cost of the overlap will be somewhat cheaper, we remove the cost of sheets of professional flooring. Total will turn out $ 705.

Collected-monolithic overlaps (SMP) with their own hands

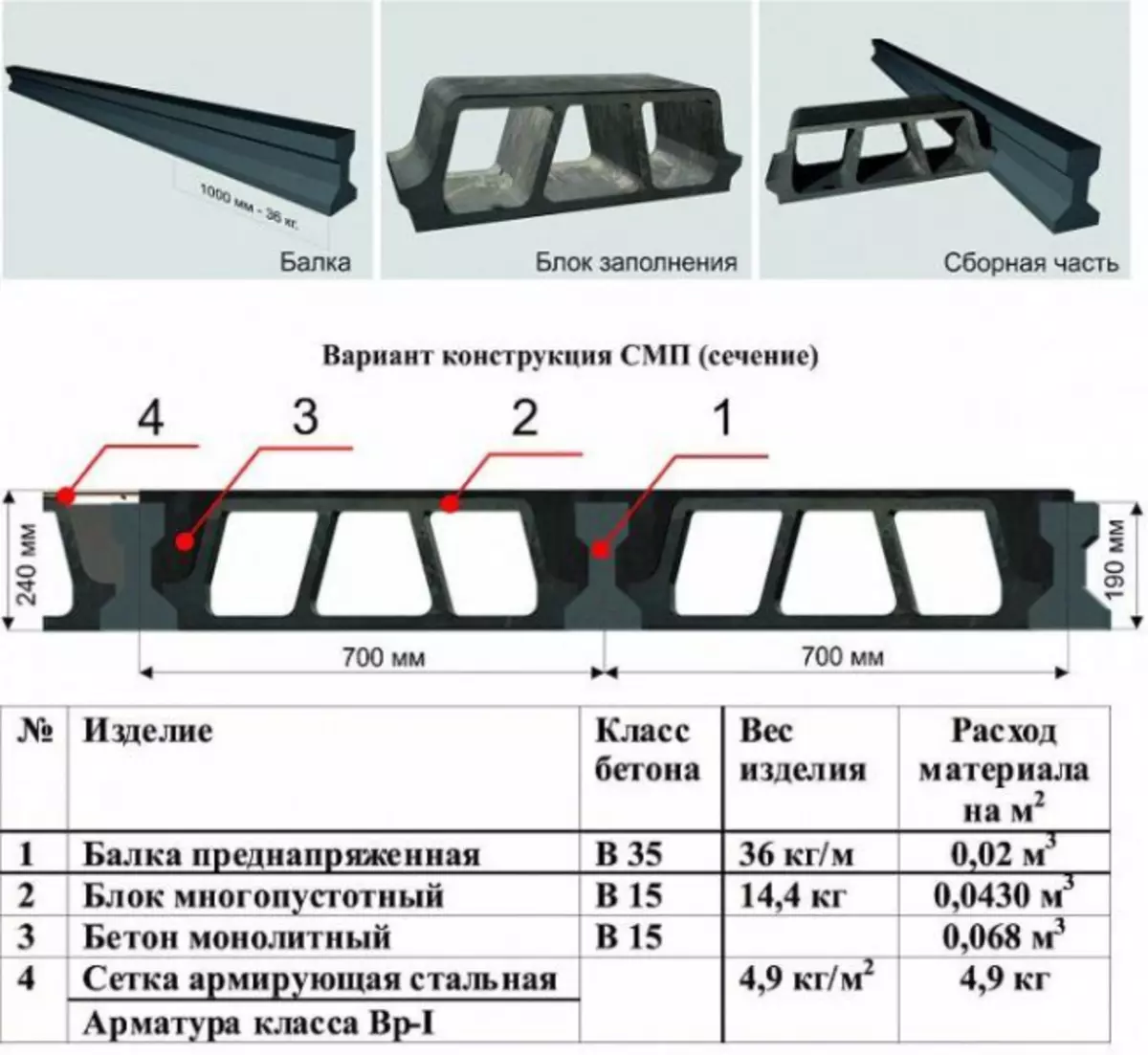

SMP of the TZHBS series is designed as an alternative to wooden floors and monolithic reinforced concrete hollow plates. SMP TZHBS is a prefabricated design, combined at the mounting stage in solid overlap using a reinforced screed.

A distinctive feature of the SMP TZHBS is that all concrete elements are made of hard solutions. In order for the production of the SMP is economically appropriate, all components of the overlap should be carried out by an industrial method on modern high-performance equipment.

Composition of SMP TZHBS

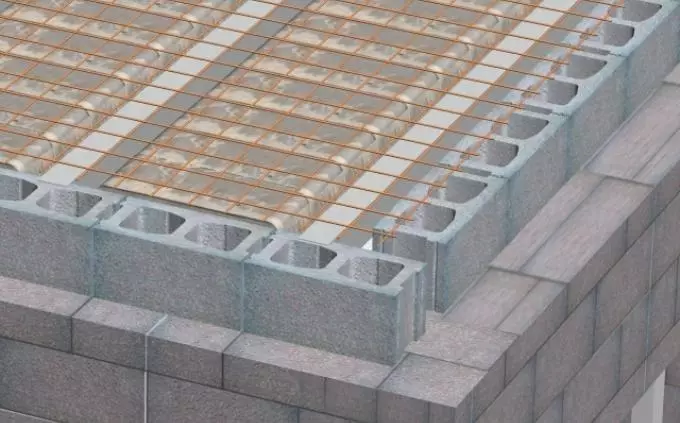

Collected monolithic floors include:

- The beams of the 2-way section made of stressed concrete;

- Multipurb blocks from ceramzite concrete or concrete laid between beams;

- Reinforced concrete layer connecting overlap in solid design.

Advantages of SMP TZHBS

- High bearing capacity, up to 1000 kg / m2.

- Refusal to perform a monolithic belt.

- High heat and sound insulation.

- The possibility of laying in the voids of engineering communications.

- Low material consumption per square overlap meter.

- The possibility of mounting overlapping with your own hands.

Mounting technology SMP

1. Delivery of SMP elements on the construction site. It is made by cargo vehicles of r / n at least 3.5 tons with a crane-manipulator. One flight provides delivery of materials for 30 m² overlap. Unloading is performed by manually or crane-manipulator.

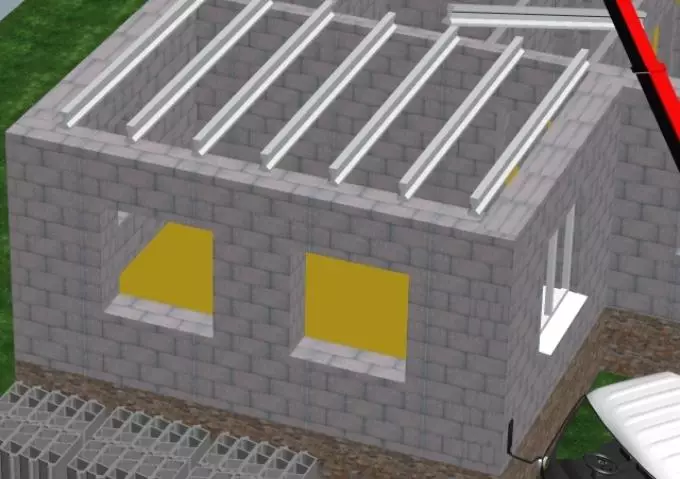

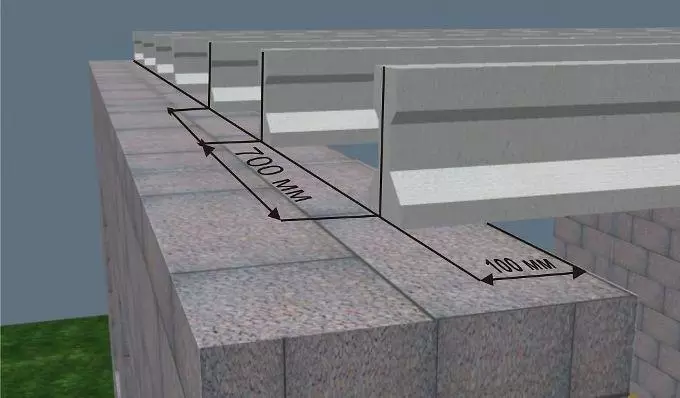

2. The device of the slab of the overlap with their own hands begins with styling of 2-meter beams on the bearing walls in 70 cm increments and with a support of at least 10 cm.

3. Laying multi-public blocks between beams.

4. Fixing extreme beams masonry.

5. Laying the reinforcing grid on the entire area of overlap.

6. Pouring the monolithic concrete screed, combining beams and void blocks into a single design. Concrete raises the space between hollow stoves and beams, creating a solid hard structure.

Variants of the device of floors for collecting-monolithic overlap

On SMP, TZHBS, you can lay the floors of any species. As an example, linoletic and parquet floors are considered. The sequence of the layers is indicated in the bottom upward direction.

Linoleam floor

- Sand layer with a thickness of 30 mm.

- Soft fiberboard with a thickness of 12 mm.

- Waterproofing from rubberoid.

- Cement-sand screed from the brand M 150 40 mm thick.

- Alignment layer of polymer cement with a thickness of 8 mm.

- PVC linoleum on a heat-sounding substrate laid on the bustylate.

Parquet floor

- Sand layer with a thickness of 30 mm.

- Wooden lags with a cross section of 80 × 40 mm, laid with a pitch of 400 mm.

- Parquet board 20 mm.

The height of the overlap with the finishing floor is 340 mm (240 mm overlap + 100 mm floor).

Monolithic slab overlap do it yourself for home

Plates used in homes are usually made of reinforced concrete. These are typical ready-made factory structures that you only need to properly put in the construction process. They have good operational properties, but there is an option with better characteristics. This is a monolithic slab overlap, and it can be made independently, without ordering from construction companies. Such a stove is not only an order of magnitude greater than ordinary reinforced concrete, but does not require special skills or specialized complex equipment for its manufacture.

Article on the topic: Homogenic linoleum: What it is, heterogeneous laying, commercial coating Tarkett, Euro technology

Compared with typical reinforced concrete plates produced in factories, the monolithic overlap has several advantages:

- The design will not have seams, which adds strength to it, since the load on the foundation is distributed evenly, along the entire surface. Thus, the overall durability and safety of the building increases.

- The monolithic fill makes it possible to experiment with a layout in the house, as it relies directly to the columns. You can create different angles and shorts, which are quite difficult to choose individual slabs of overlapping. This opens a wide scope for designer ideas.

- Finally, the monolithic design allows you to equip a safe balcony without any additional support. Creating a balcony is not mandatory, but many want to have it in a country house, so why not do it.

You can create a monolithic slab overlap with your own hands, without hiring the brigade of workers and without using complex equipment. It is enough to do everything in gradually, neatly and in compliance with safety. In addition, you need to choose high-quality materials for your facilities.

Technology Device Monolith Plate

In order to make a monolithic plate, you will need a drawing. Any construction begins with a scheme and computing. It is better to order in the construction bureau, trusting the calculations of professionals. The result will tell me what should be the right dimensions suitable for the construction of a plate, which reinforcing fittings for it to choose and which concrete from existing brands is better to use. You can try to fulfill all the necessary calculations yourself, there are schemes on the Internet for which this operation is performed. An ordinary country house, as a rule, has a span no more than 7 meters, for which the stove is suitable with standard sizes and thickness from 180 to 200 mm, this is the most common size.

For the manufacture of a new monolithic slab, the following materials will be needed:

- Steel fittings having diameter 10, or, as an option, 12 mm and a bending device for it.

- Concrete with marking M 350. You can also make a concrete solution yourself, mixing sand, cement and rubble.

- Formwork and supports for its support, you will need one support per square meter.

- Plastic coasters under reinforcing fittings for fixation.

The injection process necessarily includes several items that are performed sequentially:

- If the existing span of the building is much more than standard 7 meters or the project executed unequivocally implies support for columns, you will have to make calculation of the slab slab.

- The first step is to put a formwork to start work.

- The stove is reed with steel rods from which the frame is going.

- Concrete poured.

- Using the deep vibrator, a seal is made to enhance strength.

After the height of the walls reached the desired level, you can proceed to the creation of the slab of the overlap.

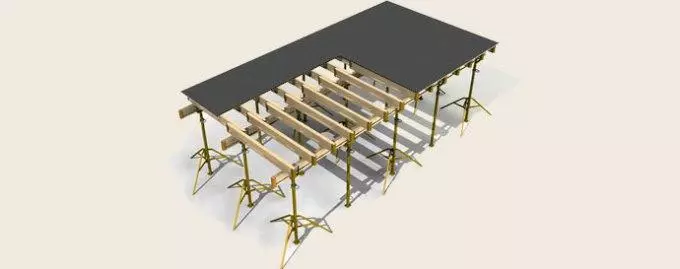

Installing formwork

An ordinary formwork used in construction is sometimes called deck, and it is it that it is necessary to create a stove. You can simply rent a ready-made, removable, which is made of metal or plastic. You can also easily make it yourself from boards or plywood sheets. Of course, rent is much simpler because the formwork is removable and collapsible, and therefore it can be easily removed. In addition, it has a telescopic device, which allows you to adjust the height.

To create a formwork manually you need to take sheets of plywood or boards. Designs made of boards need to fight well, carefully customizing wooden parts. If the slots and holes remain, you need to use the waterproofing film by turning the formwork.

How to install formwork?

- First you need to build vertical supports. If it is a leased formwork, their role is performed by metal racks with a telescopic height adjustment system. You can take wooden logs. The distance between the racks used is one meter. Racks must be removed from the wall at least for a distance of 20 cm.

- Rigels are put on top of the installed racks - these are special longitudinal bars needed to hold formwork.

- On the branches will be located a deck of plywood, resistant to moisture. The horizontal beam should be tightly restarted in a nearby wall, without leaving the holes.

- The top edge of the design used should coincide with the existing surface edge of the wall, so it is necessary to adjust the height of the racks to an acceptable level.

- Location and accurate horizontality should be checked using a construction level.

In some cases, the formwork for convenience is covered with a film with waterproofing properties or lubricated with automotive oil if it is made of metal. It is done to facilitate the removal of the formwork and make the surface of the obtained concrete slab smoothly. Telescopic leased racks are preferable than homemade wooden, because they are able to withstand considerable weight - up to 2 tons, do not break, they do not appear cracks, as can happen with homemade supports. Temporary rental of such racks costs about 3 y. e. one square.

Article on the topic: Balcony combination with room: perfect solution for a small apartment

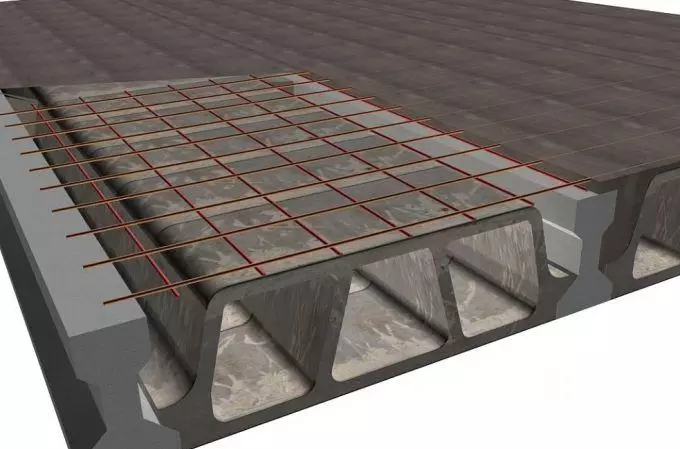

Reinforcement plate

When the metal or self-made formwork is installed, it needs to be associated with a frame of reinforcement grids. To do this, durable steel bars marking A-500C are used. The size of one cell of the resulting grid should be about 200 mm. Ponds are connected using wire. Typically, the rods are not enough for all space, so you have to connect several pieces. So that the grid is durable, it is necessary to fold the pearblings of at least 40 mm.

The grid must be superimposed on the walls, the norm for brick structures is 150 mm and more, for walls made of aerated concrete - no less than 250 mm. Between the protruding ends of the spaced rods and the installed formwork should remain a distance of 25 mm.

Additional strengthening of the future plate is sequentially performed using a solid frame of fittings. The grids are done two, the one is located downstairs, neatly located at a distance of 20-25 mm from the edge below, the other grid, the top - is placed below 20-25 mm from the top edge of the plate.

Under the bottom tile, clamps are placed from plastic to hold it at the desired distance. They are located in increments of 1 meter, at those points where the crossing of the rod framework is.

The total thickness is pre-calculated in the ratio of 1:30, where the first digit means the thickness of the future product, and the second is the length of the span. For example, if the standard span is 6 meters, then the width of the plate will be exactly 200 mm. Since the strengthening grids are located at some distance from the edges of the plate, then they need to be divided, between them there must be a gap of 120-130 mm.

Fixtors-stand are needed to dilute the posted reinforcement grids in the frame at a distance of each other. The size of the upper shelves of the fixture should be 350 mm, while the vertical size is 120 mm, the position of the arrangement is 1 meter, the fixing elements are set in a checker order, alternately.

The end locking element in the design is installed with a constant step of 400 mm, directly in the end of the frame. With it, the stove will rely on the wall.

The grid connector needs two grids to take the load as a single integer reinforcing device. Step during installation should be 400 mm, and turning to the support zone, it is necessary to cut it up to 200 mm.

Pouring plate

The optimal option is to purchase a suitable concrete at the factory, from professional companies engaged in the manufacture of goods for construction. This largely facilitates the task. In addition, if you neatly pour concrete evenly and from the mixer, the surface of the plate will be smooth and very smooth. But the pouring manually will require an inevitable break for the time of cooking a new portion of the building mortar, respectively, the solidification will go unevenly, which threatens the finished plates defects. It is better to fill with a smooth layer, about 200 mm, acting without delay.

Before performing the fill with concrete, you must not forget to establish special technical boxes in the formwork, intended for the creation of chimneys or ventilation. After filling, you need to use a special deep vibrator for concrete. This will make the structure of the slab more durable, so it will be reliable and high-quality. Then you need to take patience and leave the sprinkled surface to dry and gain strength during the period of 28 days.

Behind the forming surface, you need to carefully monitor first week after the fill and wet it with simple water, but at the same time it is only moisturized, and not abundantly pour. Formwork can be carefully removed from the slab a month after the fill. After that, the new monolithic plate will be fully ready.

The total cost of materials and devices necessary to obtain the monolithic slab overlap, as a rule, takes into account the costs of reinforcing reinforcement, the possible rental of formwork, the purchase of concrete and the short-term rental of a building mixer, as well as a deep vibrator. On average estimates, approximately 45-55 cu is obtained. One square of the erected overlap.