Laying (installation) slabs of overlapping do it yourself

So, what do you need to know to correctly install the slabs of the overlap?

Here is a list of those actions that provide reliable and durable installation:

- Actually, installation of plates;

- competent rusting;

- Filling small gaps between the plates;

- Closing the ends of the slabs in order to protect against freezing;

- Punching the hatch or lazium in the slab to enter an attic room;

- obtaining the desired size of the slab by cutting;

- Safe use in the construction of cracked plates and prevention of cracks.

To begin with, consider the theory. Various structural elements can be used as overlapping in homes:

- Multipred panels;

- ribbed pre-stressed panels of standard sizes;

- Tent panels having ribs located around the perimeter. Typically, such panels completely overlap the entire room;

- layered solid panels;

- Monolithic overlap.

Each overlap option has its pros and cons. For example, the monolithic overlap requires a lot of time for mounting and it is quite expensive. Ribbed plates, having standard dimensions, are not always suitable for overlapping the rooms, the dimensions of which are non-rotating them.

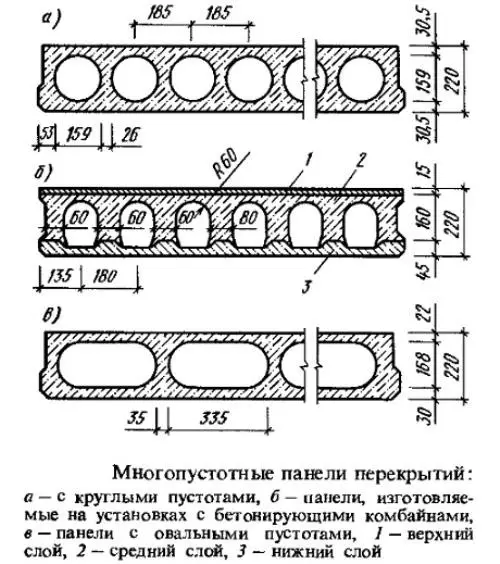

In private construction, the most common overlaps are made from reinforced concrete round-mounted plates. Empties in them can have different forms: from oval to the wrong.

Their popularity is explained by a number of advantages in comparison with other types of overlaps:

- Due to the emptiness filled with air, such plates perfectly retain heat, being thermal insulators, and also significantly increase sound insulation;

- In comparison with other plates, there are much smaller weight, reducing the load on the supporting structures.

How to shorten the hollow plate?

Row-standing plates are manufactured by ordering any sizes, but there are cases when there is a need to reduce their length or width, cut the desired shape, for example, for the erker or make a hole in the slabs to enter the attic. In such cases, the slab must be chopped by applying a grinder, scrap and cam. Despite the sufficiently high strength characteristics of the plate, it cuts down quite easily - enough 40 minutes to cut off the extra centimeters of the plate with a width of 1.2 m.

How to do it? Consider the options for cutting the slab across and along. To cut the plate across, it needs to be located horizontally, putting the lining under it and applying the lines on it for which it will shorten. Lining must be accurately under the line of markup, and not around the edges. For example, you need to cut off the stove halfer. To do this, at a distance of 500 mm from the edge, the line is carried out on the surface of the plate, and the lining is installed below it. If the lining will be not under markup, and near, with a cutting, the concrete surface will be, what is called "lubricate".

According to the marked line, the stove is cut by a brotcast with a disc on concrete. After that, you need to knock the cam on the emptiness near the cut line. The fist blows should have exactly the voids, and not to the ribs. Typically, the stove breaks through with 3-4 coup shock. These actions are repeated across the entire width of the plate. To destroy the ribs, there are shocks on them with the same cam, only already on the side, and not on top. An unnecessary piece of the plate, devoid of support from the bottom, will be saved under the weight of its weight, which will accelerate and facilitate the cutting process. Next, with the help of scrap, the lower wall of the pipe is made, under which the valve is located. The surface of the reinforcement is thoroughly cleaned from concrete, after which it is cut by the grinder using a metal disk.

Article on the topic: Several ideas for choosing a bedroom wallpaper

The resulting shortened plate will have a not quite smooth edge of a cut, which subsequently needs to be chipped with a solution with a solution that not only hobs irregularities, but also strengthens the stove.

The plate can be cut along. The technology is almost the same, but requires less effort and more time, because the length is more width. In this case, the cam needs to be divided only the wall of the emptiness walking along the plate, having previously done a longitudinal incision with a grinder on the intended line. The lower wall of the pipe breaks on the crowbar. In the process of cutting in the concrete layer there will be a smooth bar of the reinforcement grid with a diameter of 3-8 mm. They can be cut by a grinder.

When cutting fittings, it is necessary to take into account that it is tense And it can hold the cutting disc of the grinder. So that this does not happen, the reinforcement rods are slightly not renewed to the end, and then the resulting incision is finally separated by a scrap or cam shock. Another reliable way of cutting fittings - using autogen.

The comparative ease with which the round-standstop coil is cut, pursues that it is not so robust. But it is not. In fact, this stove can withstand the load up to 800 kg / m2, which is mainly perceived by reinforcement and ribs.

How to cut a hole in the hollow plate?

In the same way, the slabs cut out the hatch. Since his edges will be in sight, it is better to immediately try to make them as smooth as possible. To do this, on the outlined contour you need to make a pre-incision with a grinder.

Luke cuts over at the junction of two plates, evenly distributing its area between them. The size of the hatch is dependent on the width of the plates and the degree of their load, as well as from the type of the used staircase. The wider and less loaded plates, the more you can cut the hatch. Loads from building structures based on the plates significantly reduce the permissible hatch area. For the palter stairs, a hatch is usually 900x900 mm in the plates, the width of which is 1.2 m. In each of the plates, a hole with dimensions of 450x900 mm is done.

The use of adhesive stairs is not always convenient. They must first install, then take it, and their fixation in place is rather unreliable, especially if it is old wooden stairs. More convenient to use folding attic stairs. They are securely fixed on the lid of the hatch and add up when it is closed, without occupying unnecessary area. The dimensions of the hatch for such stairs have dimensions of 600x1200 mm, 600x1300 mm, 700x1200 mm, 700x1300 mm or 700x1400 mm. The big side of the hatch must be placed along the plates.

How to overlap the room if a little lacks the width of the plate?

When the room is worked out, it may turn out that its dimensions are not painted by the sizes of the plates, which leads to the formation of gaps between the plates or between the stove and the wall. You can cut the missing piece of existing plates, but it is long and troublesome. There are easier ways to eliminate this problem.

Take for the example the case when when mounting the plates between the last stove and the wall remains a gap of half the meter. What to do in this case? There are several options. First consider the simplest one. The magnitude of the gap - 500 mm - is divided into two parts - 250 mm. The first plate is stacked at a distance of 250 mm from the wall, then all the plates are mounted in bulk. As a result, a 250 mm gap between the last slab and the wall is. The obtained empties is set by the shlakoblock twist, from which the walls are erected. At the same time, the slagoblock is reliably fixed by resting the tile in the stove. It is necessary to place a slag block so that its holes are directed to the sides, and not up or down. The erected outer wall will additionally lit a slag block, reinforcing its fixation.

This design, although it looks unreliable, is actually quite durable. If someone doubts the carrier's ability of slag blocks, you can additionally strengthen the gaps when filling the floor screed, installing the reinforcement or masonry grid on top of them. At the same time, rods with a diameter of 6 mm are used.

Article on the topic: Funior fungus in a private house: how to get rid of

Another way to overlapping the gap is the distribution of its magnitude between the plates. For example, there is extra half meter and ten plates of overlap, between which nine gaps of 55 mm each. Why exactly 55 mm? The total value of 500 mm is divided into the number of joints - 9. The result is 55 mm.

The first plate is stacked on the wall. The second is an indent from the first to 55 mm, etc. The latter plate should be frightened to the wall.

Under each gap is tied up the board playing the role of formwork. Armature is laid in the resulting formwork and concrete mortar is poured.

Burst the slab overlap. What to do and why does this happen?

Sometimes in the construction process it turns out that the slab slab has cracked before being edited. What is the reason? Usually cracks appear with incorrect storage conditions or transportation. As for storage, the slabs should be stored in a certain way with the observance of several conditions.

Plates should fit in the stack so that they do not touch the soil. Under the bottom plate you need to put a reliable base that does not floss and does not rot, otherwise the moisture will fall on the stove, which will cause cracks.

The base should be durable and high enough. Because several plates will rely on it, it can be asked, but even when sent, the bottom plate should not touch the soil. If, when sending the base of the soil, the middle of the bottom plate will affect, the cracks will appear not only on it, but also on those stoves that are located above.

Plates are better stored in a horizontal position.

Gaskets are installed between the plates - wooden rails. When they are installed, you need to consider:

- the thickness of the rails that should prevent the touch of adjacent plates;

- The position of the rails that should be strictly one above the other;

- The distance from the rail to the edge of the plate should be 0.2-0.4 m.

Under all the conditions and the presence of a sufficiently strong base, the stack may consist of 8-10 rows of plates, which is up to 2.5 m of height. Much significantly in height is unacceptable.

What to do with a cracked stove? Can I overlap her house?

But what to do if the stove already cracked, and is it possible to use it in the future?In fact, builders often use cracked slabs for overlap, so if the cracks are small, the further operation of the plates is possible. The main thing is not to load them very much and additionally fix it.

Here are some examples, where it is better to install cracked plates:

- Purp the outer or carrier wall to 0.1-0.15 m. At the same time, the stove will rely on the three walls not only with short edges, but also long. Additional mounting of the plate is provided by higher walls that are reliably pressed. This technique is usually used for plates with sufficiently large cracks;

- put the slab on the site of installing a brick partition, which will subsequently support it;

- Mount the burst plate between two integers. There are rusts between the plates during installation, which are then thoroughly sealed with a solution, creating almost monolithic overlap;

- Put the slab in place with minimal loads. It can be used for the attic overlap, where the loads are practically absent, the main thing is that the structural elements of the roof do not relieve;

- With significant damage to the plate surface, when the crack is large (about 4-10 mm) or several of them, you can only use it part, cutting off damaged.

If you do not inspire confidence-mounted bursting stove, you can strengthen its strength by enhancing the floor screed reinforcement on the top floor. The reinforced concrete screed will evenly distribute the load between all the plates and will strengthen the design.

Sealing joints between plates

The following question in question is the entry of rusts. Rust is a place for docking long side sides of the adjacent plates. For solid and solid overlap, all rusts must be powered by a solution. Round-standing plates have locks on the side of the sides in the form of round recesses. When pouring rusts, these recesses are filled with concrete, providing a reliable clutch of the plates. Such a collection overlap works practically as a monolith.

Article on the topic: Crocheted Curtains: Step-by-step instructions and schemes

Among the slabs can be crafted, having incorrectly made side sides with locks. When they are connected, the excavation is lower, while at the top of the plate are snugged with each other. As you can easily guess, foul over the concrete such Rust at first glance is problematic. But not everything is so scary. For sealing the defective rust, the neighboring plates are not joined in principle, but with a small gap about 2-3 cm. The gap should be in the upper part of the plates where they can stick. From the bottom of them along the entire length of the rust, a wooden board is tied up - a formwork for the fill of concrete. A solution is poured through the upper gap in the RUST. By consistency, the solution should not be thick, it should be evenly spread over the entire length. But too liquid it should not be done either. After the solution is frozen, the edge of Rusta can be considered over.

Black Plate Styling Technology

What else should pay attention when installing round-standing plates? Of course, for safety equipment. Installation is conducted at height using special equipment, which must be considered when working.

Plates rise and stacked using the car crane. The plates are laid on the solution, so for 10-20 minutes they can easily move scrap, until they occupy the right position. On the bearing walls, the plates should be based on them by 0.12-0.15 m.

It is important to create the most comfortable conditions when laying the plates. For example, dishes with a solution can be raised to the first installed plate to do not go down after it. Rusts are flooded with the same solution. Such, at first glance, the little things often take a lot of time and strength.

After the installation is completed, they need to close their ends to protect against freezing. If the stove rests on the outer wall, the end of the end will also further save the heat in the house and will not give to get inside the cold.

For sealing ends of the slabs, you can use one of the following ways:

- Fill the emptiness of the mineral wool pipes by approximately 0.2-0.3 m in depth;

- Pour emptiness with a light concrete solution by 0.12-0.25 m in depth or install concrete traffic jams;

- Close the emptiness by the incident brick on the solution, and then close the surface with the solution; You can insert one-year-old stouting brick into the hole.

In some cases, the stove is too close to facial masonry. In the absence of insulation between them and non-sealed ends, the stove will begin to freeze in the cold season, covering ice indoors. Such a stove will be the source of the cold in the house, and with the included heating on its surface will form "dew" due to a sharp difference in temperature. If such plates are already available in the finished house, you understand the case, disassemble the walls and nobody will close the ends. The problem can be solved in a less radical way. For this, the perforator is drilled by a hole in the frozen pipes from the bottom side of the "problematic" plate. A tube with a slope toward the outer wall is inserted into the resulting hole, through which the mounting foam is blown. At the same time, a tube from a foam, setting in a pipe to a depth of 0.1-0.2 m. It will play the role of the heat insulator.

Close the ends are needed not only from those plates that are based on the outer walls, but also in those relying on the internal capital walls. For the construction standards, the ends are close at the slabs starting from the third overlap and below. For example, a two-storey house has three overlaps: between the basement and the first floor, between the first and second floors and between the second floor and the attic. In this case, they close the ends of the plates in the attic ceiling to enhance the design that perceives a significant load from above. The ends are poured with a concrete solution or are laid by one and a half bricks. It is easier to do it easier and more convenient before installing the plates, putting them on a horizontal surface.