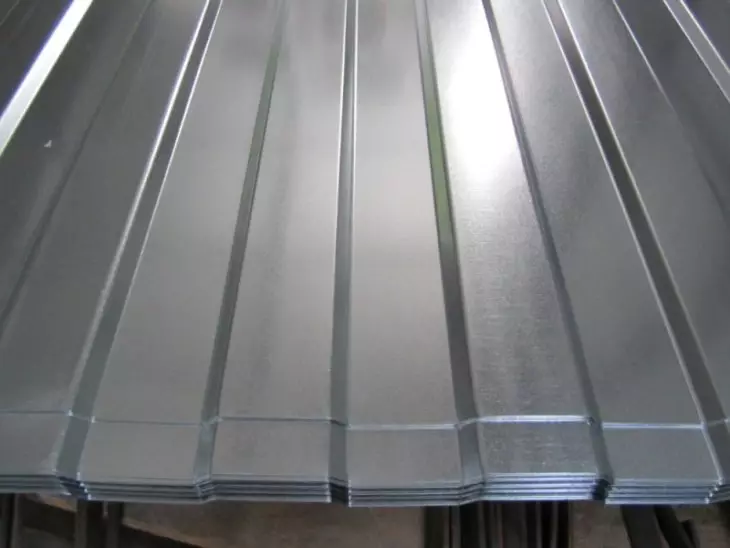

When repairing metal structures, coatings of roofs and canopies today is very popular with a leaf of galvanized iron. This finishing of the profile reduces the number of folding compounds, and this, in turn, increases the tightness of the roof.

Gray galvanized roof

Next, we talk about how and with the help of which materials are painted metal surfaces.

What is galvanizing and what is it needed for?

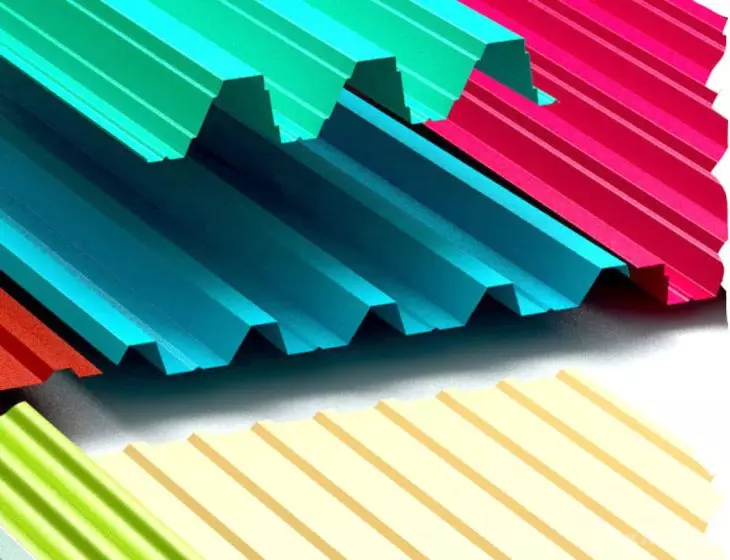

Galvanized roof

The technology of applying zinc on the black metal was invented and is activated at the same time in 2 countries - in France and England. With the help of such a discovery, it was possible to protect the iron and steel structures from corrosion (this is especially relevant for the roofs, pool pipes, window sills, etc.).

In those distant times, it was customary to use the technology of hot dive, and now the galvanic method is almost everywhere. As the basis of the master they try to choose high quality materials that are presented on the market in different steel stamps.

From that time, the galvanized leaf has become very popular among the roofers thanks to such features as:

- long service life;

- Material storms withstands atmospheric oscillations;

- Prost and easy to use.

Today, the steel sheet of galvanizing can be seen not only on the roofs of houses, but also on the roofs of garages, warehouses, buildings under offices and plants. Also, this material is drawn up window window sills, pipeline and stocks of pools.

But, as it became clear, Zinc itself can also give in corrosion, after which the galvanized sheet is covered with a "white rust". To avoid such trouble, it was decided that the steel needs to be painted, and it was the painting of the product that would provide him with a solid level of protection against environmental influence and atmospheric oscillations.

Today, 2 reasons are known for which galvanized profile is better to paint:

- protection (zin tier is too thin, so it will be subject to natural cataclysms, the effects of salts and exhaust, after which the rust will be covered);

- Decorativeness (if you paint galvanized iron sheet, it will acquire a decorative appearance and will look more attractive than the untreated area of the profile).

Article on the topic: Repair of the ceiling of plasterboard with their own hands (photo and video)

What materials offers a building market for coloring galvanizing?

Gray galvanized roof

Over the years, the manufacturers of paints and varnishes have carried out experiments and concluded that the galvanized profile is better after installation (after the leaf aging naturally is completed). A year later, under the influence of atmospheric oscillations, the profile galvanized is prepared for the upcoming painting:

- White rust comes with waterpipes and efforts of swimming pools;

- Roughness is formed on the design;

- The level of adhesion will increase.

Brief instruction manual of work, which will help solve the task, looks like this:

- It is necessary to clean the galvanized iron sheet from contamination, fat spots and salts (a washing powder or other alkalis-based solutions are perfect for this);

- Remove the remnants of detergents with clean water (it is better to do under high pressure) and dry the surface well;

- Cover the steel galvanized profile with a roller, and then apply a layer of coating enamel (if the composition of the paint allows, structures can not be bled).

The most acceptable options for painting metal surface

How to paint galvanized iron?

To paint the area of profile from galvania very often choose a special matte paint on an acrylic basis, which is intended for galvanized. This is a mixture of cycro. The composition of this material includes active anticorrosive components in an organic solvent. Also, the tool can be used if you need to paint the area of steel or aluminum structures.

As a rule, cycrole is used to protect structures from any materials, ranging from steel, ending with roofing tin.

Such paint is characterized by a high level of resistance to light and shelterness, well copes with high humidity and natural cataclysms. The substance is convenient to use and has a fairly high level of adhesion, as well as quite popular when placing pools and window sills.

Article on the topic: Practice Application of wallpaper painting in the kitchen

Material application technology allows not to use priming, and the application is performed in one layer.

A substance is also popular, called Silver - this is an anti-corrosion aluminum single-component enamel on a waterproof basis, which is designed to process structures from galvanizing and ferrous metals.

Also do not forget about alkyd enamel, because some of its characteristics are similar to powder substances. After using alkid enamel, the processed area practically does not respond to fluctuations in temperature indicators, steadfastly withstands precipitation and exposure to ultraviolet rays. But, remember that it is possible to apply such a coating on a cleaned and thoroughly dry surface.

The comparative characteristics of the most popular paint representatives on galvanized are shown in the table below.

| Indicator | Cycrole | Spannuux |

| Feature | Protection against moisture, high temperatures and ultraviolet rays, salts | Increases adhesion, does not require pre-primer, quickly dries, prevents corrosion and chemical impacts |

| Suitable surfaces | Only for galvanized surfaces | For all types of coatings |

| Diluent | Ethyl acetone, xylene, butylacetone | Organic solvents or routine |

Pray galvanized sheet

Choosing enamel for galvanized need to take into account a number of criteria that:

- must ensure the protection of galvanis from atmospheric phenomena (humidity, sun, precipitation, salts);

- should not burn out on the sun's rays;

- will quickly dry out;

- Significantly extended the operational term of the galvanized;

- give surfaces of attractiveness.

As you can see, the use of protective means has confirmed its demand. The area-treated area of galvanized will serve you for many years, and will also reduce financial waste for repair work.

Armed with higher councils set forth, you can easily paint the galvanis on your own, the main requirement of successful work is a properly selected technology.