Why the gas column needs cleaning

In any column, a layer of soot and scale accumulates in time. For the normal operation of the device, it is, of course, you need to delete. How to clean the gas column yourself at home, not everyone knows. Previously, this procedure, mostly, trusted specialists. But having some skills, observing the rules and safety equipment, you can clean the gas column yourself.

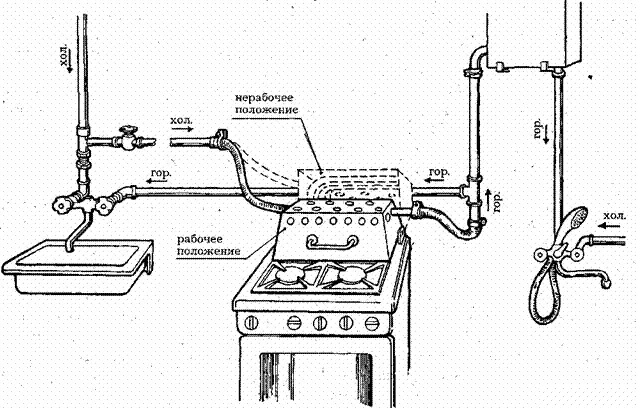

Scheme of the gas column.

But first it is necessary to take into account: before cleaning the column, the situation simply can not be brought.

There are several ways to mitigate water. For example, if you installed a high-quality filter, most of the scale will settle on it, and it is faster and easier to be replaced than clean the whole column. But there is another option.

One of the most optimal methods is an electrium. This device is fixed directly to the pipe itself, and it affects directly on the flow of water passing through the pipe. As a result, the formation of scale occurs less intensively, and one season of intensive operation of the device can be skipped without cleaning.

The work of the column consists in heating the water by burning gas. Consequently, the gas column belongs simultaneously to two varieties of household appliances - plumbing and gas.

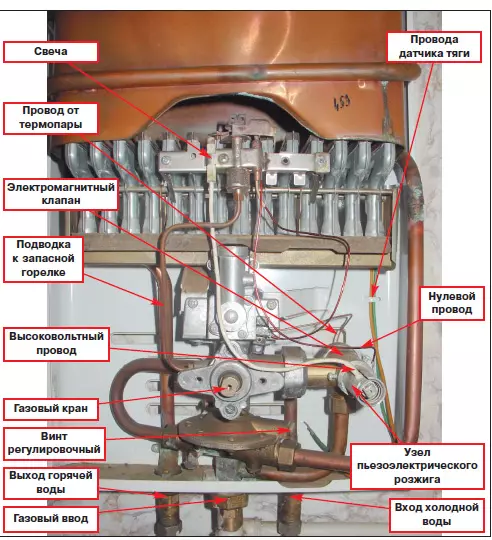

Scheme of the gas column device.

As a rule, the formation of Nagar and the accumulation of soot, which must be periodically cleaned, occurs in the gas part of the column. Also, it is sometimes necessary to clean the jackets - the calibrated holes of the stamp and burners.

The main problem of the tap of the column is precisely. Cutting - salts dissolved in rigid tap water dropping during evaporation of water precipitate and deposited on the walls of water pipes of the gas column. Special problems create a scale in the heat exchanger. So that the water passing over the burner has time to warm up, the flow of water in the heat exchanger is distributed over thin tubes. Skip, scoring the channels of thin pipes of the heat exchanger, can significantly reduce the efficiency of the entire column, and sometimes it can make it work completely impossible.

Article on the topic: how to sew curtains with folds: the calculation of the fabric, tips, features

How to find out what time it is time to clean the gas column

Cleaning the column is necessary if:

- The column is disconnected by worrying only for a while, or does not turn on at all. In this case, gas and water in the column are accurate;

- All the time the thermal protection sensors are triggered. Scale has thermal insulating properties and has a porous structure that interfere with the full cooling of the column;

- The efficiency of the column significantly decreased: the burner is working normally, and the water heats up much weaker;

- With normal pressure at the entrance - a weak head at the outlet of the gas column. Water cannot leak through the channels, blocked by scale.

Before any operations with a gas column, it is necessary to overlap the gas and water supply cranes!

In the process of cleaning the gas column from scale and plaque, the following tools and materials will be needed:

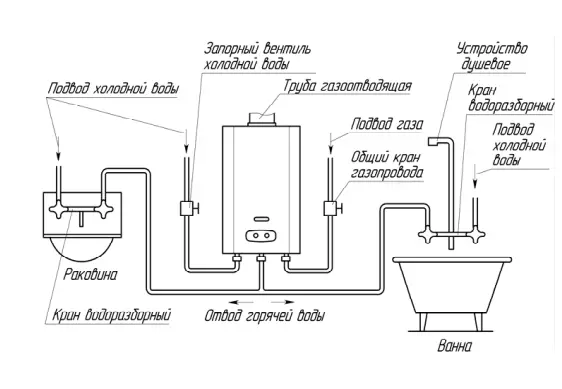

Scheme of installation of the gas column.

- crushing cruciform;

- screwdriver flat;

- a set of horn keys of suitable size;

- funnel;

- Metal brush;

- copper wire;

- sealing gaskets;

- acetic essence;

- Cleaning agent Silit;

- VD-40 liquid;

- soap for the preparation of the solution;

- 100 g of citric acid.

Cleaning the water bridge

The water intake unit is located at the inlet of the water-conductive column system, is equipped with a mesh filter to prevent the heat exchanger tubes from scoring the sediment and rust particles, as well as the automatic gas supply membrane when the water crane is turned on.The cleaning process is as follows:

- Remove the water-receiving assembly from the column body;

- Unscrew the connecting screws and open the housing;

- Clean the filter and rinse it with a strong water pressure;

- Check the state of the membrane. It should be flat if the membrane has a clear concrete pronouncement, it means that it worked its resource, and it must be replaced. The "native" membrane of the old column can be replaced by a modern silicone membrane, which has a much longer service life;

- Close the lid of the water intake node, "nag" the screws and alternately tighten the diametrically opposing pairs of screws. In this way, a uniform tension of the membrane occurs.

Article on the topic: Velvet curtains: types of tissues used

Cleaning heat exchanger

Disconnect the output tubes and input to the heat exchanger. In the event that the cleaning of the heat exchanger is carried out irregularly, the mounting nuts can be scored by scored by disconnecting them. In this case, the VD-40 special liquid should be used, which can be purchased in any automata. With the help of the oil, it is necessary to pour fluid to the junction of the nuts. You can use and "Silit" from scale. After 20-30 minutes, you can unscrew the nuts. If it does not work, then try the nut from all sides.

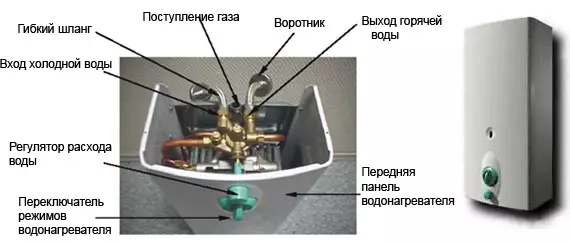

Diagram of the water receipt node.

Next, follow as follows:

- Disconnecting the heat exchanger, with a funnel, pour into it a solution to remove scale. A solution of 100 g of citric acid, divorced in 0.5 liters of hot water, is well suited as it. Clean the heat exchanger can also be also a cutlery vinegar of 9%, diluted with water in a ratio of 1: 3. It is not recommended to use hydrochloric acid, since it can join the reaction with the metal from which the heat exchanger is made, and this will only aggravate the situation. Solution Leave inside the heat exchanger overnight.

- Drain solution, thoroughly rinse the heat exchanger. If it is not removed from the walls from the walls, it can score the heat exchanger tube, so it is necessary to rinse the heat exchanger with a strong pressure of water from under the tap. To do this, you can use tubes of a suitable diameter.

- Put a washed heat exchanger into place, tighten the mounting nuts, pre-replacing the sealing gaskets.

Removal of nagar and soot

Unlike the plumbing part, it is impossible to disassemble the gas part of the column, because only a qualified master or an employee of the city gas service should be engaged. The only thing that can be done here to remove the sleeve is to consider the nagar from the burner jibers.

The jets should be cleaned with fine copper wire. Cokelieve with a metal brush. It is immediately desirable to check the column for gas leakage. To do this, it is necessary to prepare a soap solution, which then apply to all places of compounds of gas pipes and aggregates. Education at the junction of characteristic bubbles will indicate a gas leakage. If you suddenly discovered leakage - overcase the gas and call 104.

Article on the topic: Replacing the distribution panel and the introductory cable

You can minimize the need to clean the column using prophylaxis. The longer operation of the gas column without cleansing and failures contributes to the use of filters and devices designed to reduce water rigidity.