In recent years, leaf professional flooring has taken a leading position among materials used for fences.

Low price, simple installation and durability. These three factors are decisive when it is selected.

The stability and strength of the metal fence is provided by pillars. They are the most responsible element of the design.

If the step and depth of their installation is incorrectly selected, errors are made when fastening the trim, then the owner of the estate will soon have to be repaired.

In this article we will talk about what pillars are needed for a fence from the professional flooring and how to establish them. Having received useful information, you will avoid annoying mistakes and unjustified waste of funds for restoration work.

What poles are suitable for fences from the professional flooring?

Strictly speaking any. However, we are interested in material, the most durable and durable. Wood - the least suitable option. Its service life is much less than that of the metal.

By installing the pine rack treated with antiseptic, you will have to remove it after 6 years. The use of larch or oak extends the life of a frame, but increases its value. Therefore, wooden racks are most often used for temporary fences.

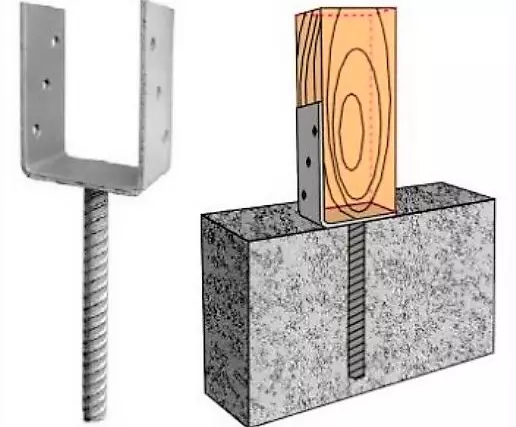

You can exclude the contact of wood with a soil, making a metal adapter and slaining it in the foundation. However, this option is not suitable for high fences experiencing intensive wind loads. Another similar option is to use a piece of the profile pipe as a steel sleeve in which the post is inserted and then concreted.

The next applicant for the title of reference design is asbetic pipes. They are inexpensive, are not susceptible to rotting and strong enough. Their disadvantages include the fragility and the complexity of the fastening of the runs.

It is impossible to leave asbestos-cement pipes. Rainwater, hitting them as a well, winter will freeze and break the walls. Therefore, after installation, they are filled with cement mortar or before the start of work they put plugs from both ends.

Article on the topic: How to assemble a coffee table with your own hands

The reinforced concrete is also suitable for the manufacture of racks. The only requirement that needs to be considered at the Pouring Stage is the installation of metal mortgage plates to which runs will be attached.

The technology of industrial casting of concrete in recent years has stepped far ahead. Therefore, instead of the time-consuming "home needlework", we recommend buying aesthetic prefabricated designs.

Metal is an unconditional leader in the field of "Zaming". It is perfectly combined with a corrugated floor, keeps wind load well and maintains strength for 50 years. The only thing that is required of the owner is once in 3-4 years to update anti-corrosion protection.

The shape of the cross section of standard steel columns is a circle, square and a rectangle. The profiled tube is more convenient in the installation and for this reason is used more often round.

Fastening of runs can be performed in different ways using welding, additional elements and threaded connections. This is another advantage of steel racks.

The fence pillars from the professional leaf are often made from bricks. However, without metal and in this case will not be able to do. It is required for the manufacture of mortgage parts to which lags are fixed, and imparting the design of sufficient stiffness.

The basis of brick columns serve reinforcement rods or profile tubes. The space between masonry and metal is filled with mortar.

The disadvantages of brick racks include a high price, complexity of masonry and high weight, requiring fillings of a durable foundation. In terms of aesthetics and durability, they are superior to other types of intricate supports.

To install the fence from the corrugated floor it is beneficial to use screw poles. These are the hollow steel pipes of a square or round profile, equipped with a wide blade.

Using them, you can collect a durable frame without earthworks and concrete. The rack-pile is screwed into the ground to a depth of 0.8-1.2 meters and firmly holds in it due to wide blades. On soft soil, the screw columns can be put on manually using a special mechanism for capturing and rotating.

Main points of Montaja

In order to properly install Poles, you must select the optimal way to fasten them in the ground. To do this, consider the composition of the soil. If it is sandy and tight enough, then the racks can be placed without concreting into the prepared wells or by driving.

Article on the topic: how to use the electric water heater

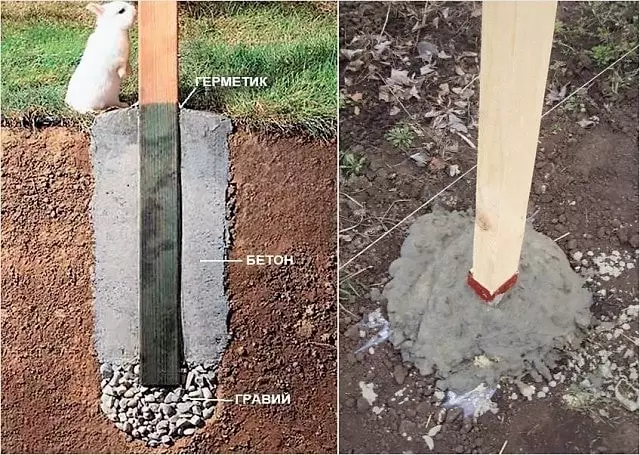

The main danger for any fencing supports is frosty powder, pushing them out of the ground and the boxing frame. In the sand, well-skipping moisture, the deformation fence does not threaten. Concrete in this case is used to increase the contact area of support with soil.

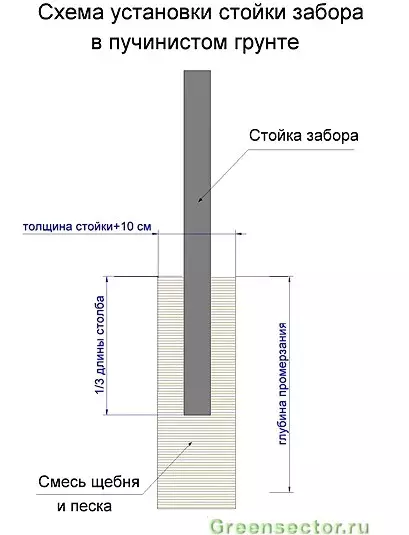

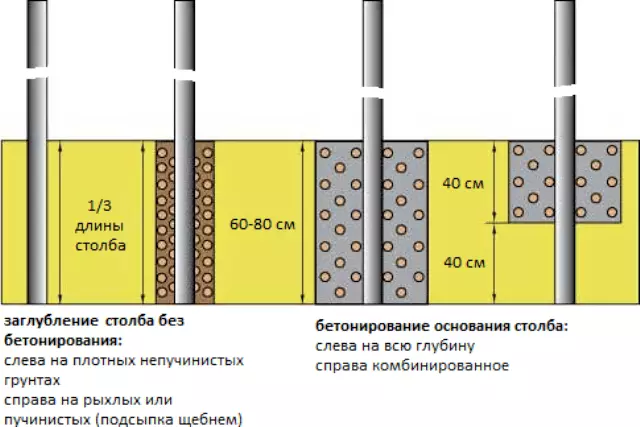

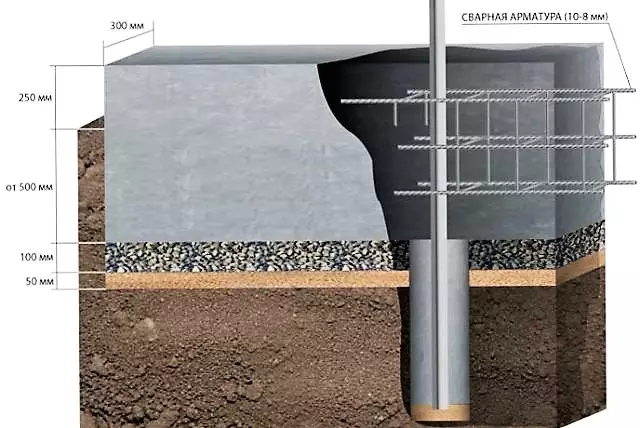

On dense sandy soil it is recommended to plunge racks at least than 1/3 of their length. On loose and bunched ground, the depth of the seal remains the same, but the well should be drilled with a diameter of 100 mm larger than the column width and necessarily lower than the depth of the seasonal freezing of the soil.

Having made this work, the bottom of the pits snapped with rubble with sand to the setting of the racks. After mounting the support around it, a mixture of rubble with sand is falling asleep. Water flowing, it will protect the pillar from the pushing the frozen soil.

Concretion can be performed by one of two ways:

- Traditional (dig a pit, they lower the support in it and poured concrete);

- Combined (a well bury to a depth of at least 80 cm, put the rack and dig a wide hole around it with a depth of 40 cm for concreting).

It should be noted that the second option is more economical than the first consumption of concrete, although more difficult in performance.

The fence racks can be associated with a small-breeding ribbon woodworker. It increases the rigidity of the fence and improves its appearance.

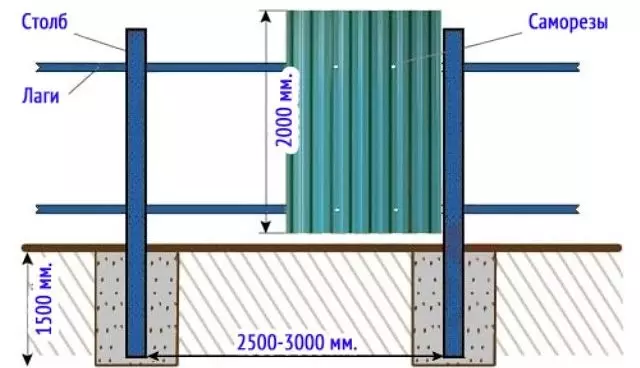

For the collection of steel pipes, you can use different sections of the profile. More often, the supports are made of a square tube 60x60 mm with a wall thickness of 3 mm or rectangular 60x40 mm (wall 3 mm). Racks from round meal pipes are convenient when mounting the runs. Therefore, they are used less often.

The second question that should be solved before the start of work is the distance (step) between the columns. Profile pipes are supplied in the form of 6 meter whips, so it is more profitable to reduce losses to cut them on 3-meter pieces.

Article on the topic: Characteristics of gas boards Bosch

The optimal size of the cross section of the runs (Lag) is 40x20mm, the wall thickness is at least 2 mm.

The distance between the lags depends on the height of the fence and is in the range from 1.2 to 1.6 meters. From the bottom of the sheet to the ground or to the top mark of the framework of the foundation, leave a gap from 5 to 10 cm.

Installation of metal pillars and frame

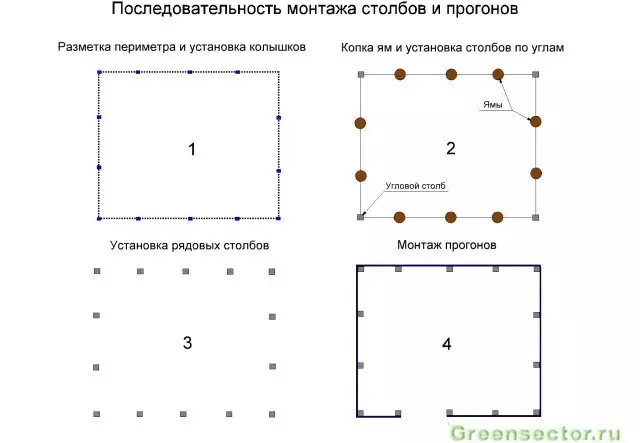

The first stage is the markup of the contour of the fence using a roulette and cord. In the course of this work in the ground, pegs, noting the places of pokes of the pits.

First put, align in terms of level and concrete pillars at the corners of the site. After that, pits are digging by private racks. Between extreme supports, the cord is tightened and ordinary columns are set.

Attention! To protect against corrosion, the lower part of the support must be brewed with a steel plate and coat with a protective composition. The top covers are welded after the end of their installation or put in them special plastic plugs.

Double distance control during the installation process is necessary. When drilling and coppe, the holes are deviated from the intended points of installation of the supports. The metal does not forgive mistakes, so the distance between the rack centers must be withstanding up to 1 cm.

Having placed supports, they are temporarily fixed with wedges or pieces of bricks and once again check verticality and step. After that, you can pour concrete or make a sinking hole with a sandy-rubble mixture.

By giving a concrete of 7 days for a durability, you can start the installation of lag (runs). They are fixed on welding or threaded connections. Welding technology is used more often because it is easier and faster. Aligning the run by the level, it is grabbed to the rack, once again check the "horizon" and fix the working seam.

Having gathered a metal frame, you can start the attachment of professional flooring with special self-tapping screws.

Video on the topic: