The accumulated rain or melt water delivers a lot of trouble to people, technology and the surrounding objects. It must be in a timely manner in the storm sewer or simply beyond objects. For this purpose, special drainage systems are used. On them water rushes to the place intended for it. The main component of such a system can be a tray of drainage concrete with grille. This is an oblong capacity, the cross section of which can be square, rectangular or rounded.

What is made by drainage trays

For the production of concrete trays, various types of fibrobeton are used. Grinding polypropylene fibers are introduced into the finished solution, which reduce the shrink deformation of products, as well as increase their resistance to bending efforts. Metal fiber can also be introduced into the concrete.Reinforced concrete drainage trays are also common, which are manufactured using cement brands not lower than M 500 and additional reinforcement.

All channels, including those having vertical waters, are equipped with lattices. It is necessary for their protection against leaves and other garbage. The choice of material used lattices depends on the location of the highway and the intended load. Lattices are attached to concrete through special screws. They can be removed for cleaning.

Where are used

These products are used only in combination with solid coatings Since the drainage system is designed to remove moisture from the ground surfaces.

Concrete drainage tray covered with grid

Pump sewage trays Concrete are used in the following places:

- on the streets and pedestrian walkways covered with paving tiles or asphalt;

- On the platforms covered with concrete. It can be airfield zones, sea and river ports, military facilities;

- on parking;

- at gas stations in combination with tiles or asphalt;

- on large squares in cities;

- in the territories of enterprises, inside shops;

- Near various infrastructure facilities. Included with the breakfast provide high-quality protection of buildings from tales, waste and rainwater.

Article on the topic: how to make a light tie with your own hands in a private house

Thanks to the drainage of concrete gutters, wear resistance and durability of road and other solid coatings increases.

Tip: Do not attempt to set up a concrete system of plum near the house, putting trays directly into the dug ditch. The land is prone to bubbishness, especially in winter. The result will be the displacement of the trays, a violation of the direction of the drain, losing the design of its type.

Types of drainage trays

By the method of manufacturing trays, concrete is divided into 2 groups:

- Made by vibration. Sealing material is provided by the vibration of the desktop and the fill form;

- Made by vibropressing. The material is compacted with the press. Such gutters do not have inside air bubbles, so the occurrence of cracks in their structure is unlikely.

By your device, the channels are divided into such types:

- ordinary;

- Channels with vertical catchment.

Concrete channels can be equipped with various types of lattices:

- cast iron lattices (their surface can be galvanized);

- Steel grilles. Stainless steel can be used for their manufacture. Also, the surface of the lattice can be galvanized;

- Plastic lattices (from very durable plastic species).

Cast iron grille for drainage tray

In addition, the grilles can be cellular or slit. For example, the tray of the drainage concrete with the slit cast iron grille can be used in places with the largest weight loads.

Depending on the location and tasks, concrete gutters can be used for the following purposes:

- for drainage;

- for laying cables;

- For the arrangement of the heat mains.

Also, trays can have an inner bias for water flow or be without a slope.

Dimensions and volume

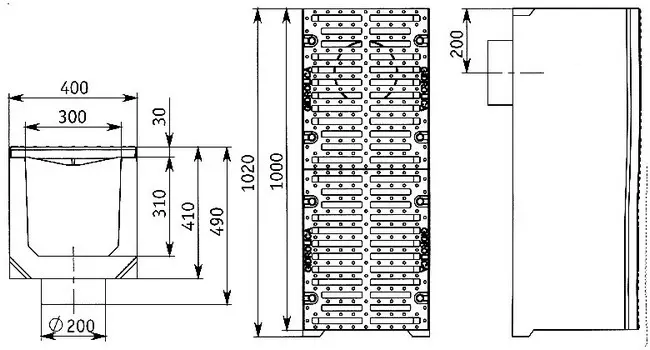

The standard length of all trail elements is 1 m, although it can be more, depending on the width and weight of the tray. Their width can vary in the range of 0.14-4 m, and the height is in the range of 0.06-1.68 m.

Dimensions of reinforced concrete trays

The volume of various reinforced concrete trays can differ significantly, but the following types are most often used:

- L-1-7, as well as L-2-7 with a volume of 0.07 cube.

- L-3-8 with a volume of 0.14 cube.

- L-300, the volume of which is 0.3 cube.

Article on the topic: Drip irrigation systems: manufacturers, equipment, reviews

Standards of drainage products

Concrete drainage products must meet the existing European standard EN 1433, which defines their appearance, operating conditions, labeling and limiting load. All products are assigned a certain class corresponding to the maximum weight affecting the products:- Class A15 - maximum weight 1, 5 tons.

- Class B125 - maximum weight 12, 5 tons.

- Class C250 - maximum weight 25 tons.

- Class D400 - maximum weight 40 tons.

- The E600 class is the maximum weight of 60 tons.

- The F900 class is the maximum weight of 90 tons.

The progress trays are produced in two categories:

- Standard series - products are able to withstand a permanent load of 1.5-25 tons. Products of this category are used for pedestrian and automotive coatings, car parks, roads with narrow (up to 50 cm) of the roads.

- Enhanced series - elements are capable of withstanding a load of 40-90 tons. These are very durable trays used on any kind of road surfaces, airfields, in industrial shops, in loading and unloading zones.

Benefits of concrete tray

- Concrete is not subject to corrosion, therefore its durability is calculated in several decades;

- Frost resistance of products and their ability to carry the temperature differences without changes makes them suitable for operation in any conditions, with any climate;

- The material is not destroyed due to the reinforcement with fibers or metal;

- Trays Water-aided concrete concrete with grille have a solid weight, which guarantees their immobility even with abundant precipitation and high sewage levels;

- Concrete from an ecological point of view is flawless, as it consists only of natural components. Such products do not harm the environment and people.

- Trays are practical and easy to design. They do not require care with the exception of periodic cleaners from garbage;

- The value of the material is relatively low, and their payback occurs quite quickly.

In the photo, drainage concrete gutters

Installation of drainage trays

Before starting the installation of stovery sewage trays, project documentation is pre-working, where the location of the waterways and their parts are noted, the system equipment, the final estimate for the project.

Tip: At the preparation stage, you need to calculate all the nuances of the installation of the gutters, prepare the elements of the system in advance and agree about the rental of special equipment. This will make it all cheap and quickly.

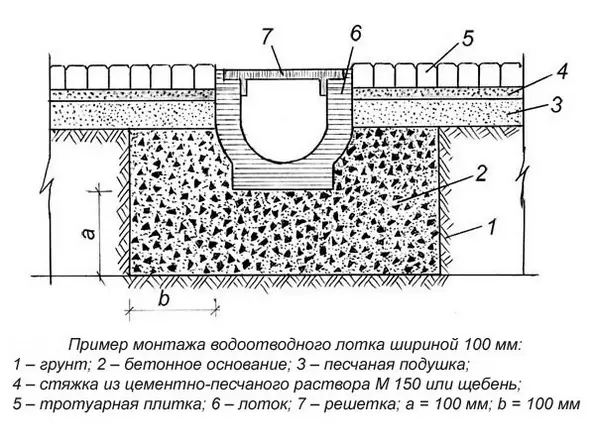

Installation of drainage channels is performed in several stages:

- The trenches of the corresponding sizes are prepared. They should be more than the dimensions of the trays. It is necessary to strengthen the soil at the location of the structures. The soil in trenches is tamped until the density is achieved.

- A layer of sand falls asleep in the trenches.

- A layer of concrete is stacked over the sand pillow, which will later serve as a support for concrete trays.

- Through loading equipment, the products are installed in the trenches, on the concrete layer. Such a fitting pillow does not allow the gutters to shift when the load occurs.

- Each tray is rain concrete strengthened on the sides of the liquid concrete solution.

- To prevent the dishonesty of the trays together be fastened by the groove connections. If it is necessary to hermetically seal the joints between adjacent elements, an acrylic or bitumen sealant is used.

- A grilles protect the system from getting garbage from top of the channels.

- The drainage system is connected to the storm sewage. Typically, a sand broker is installed at the end of the trays.

Article on the topic: Living room design, living room combined with hallway

Installation of drainage trays

It should be noted that the level of the installed lattice must necessarily be below the surface level of the coating at least 5 mm. To ensure a samothek falling into water channels ensure In directions of drainage well or central water receiver.

Installation of water removal systems can be made both on a re-created base and already existing coating. If the thickness of the existing base is insufficient for the stable placement of the elements of the system, it is reinforced by the method of increasing the thickness of the concrete pillow.

A competently mounted wastewater system using concrete trays with lattices will provide timely removal from the coating of the incoming water and protect any coating from destruction.