Reliable foundation want to have everything without exceptions. And one of the most reliable and predictable is a belt. But the monolithic belt foundation is built long: only on the assembly of the formwork leaves from three days, and still to knit fittings, then concrete and wait a few days until he gains at least half of the strength. It will take at least two or three weeks. Well, if there is such a reserve of time, and if it is not? There is a way out: smart people came up with a part of the work to transfer to the enterprise - there are concrete blocks - FBS. Of these, the foundation is recruited, which is called - the band belt. The foundation from the FBS is easy to make it yourself.

When using such technology, the foundation is collected from reinforced concrete blocks of different types and sizes. Therefore, it is often called block or team. All this is the same type.

Advantages and disadvantages

The most important plus of a collection belt foundation from the FBS is a small resource of the time that is necessary for its manufacture. The assembly takes only a few days.

The main disadvantage: it is not monolithic, therefore it is possible to put it everywhere and not always. Normally there are prefabricated ribbons from blocks on dry, not inclined to beanted soils. Under other conditions, the calculation is required, and better - professional.

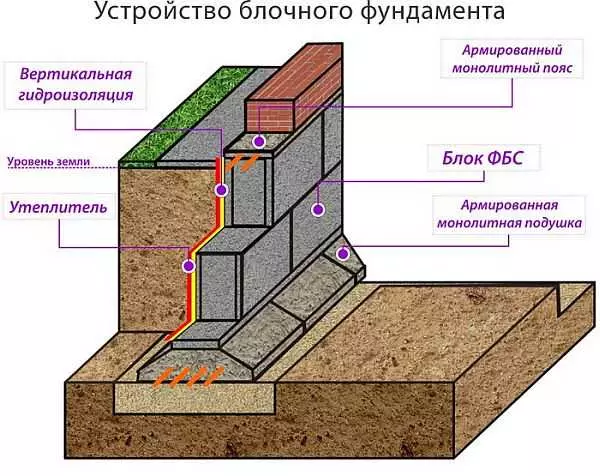

Device block foundation

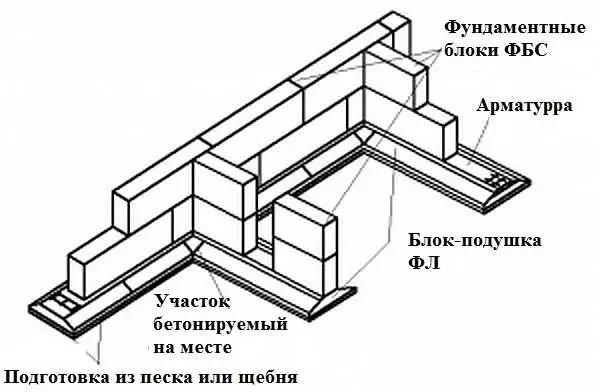

It should be noted that the prefabricated foundations must necessarily be carefully hydroizing and insulated. It is also necessary to make a warmed break. These are the necessary conditions for their normal operation.

If we compare the ribbon monolithic and block foundation, then such a picture is identified:

- Monolithic is built long, block - quickly.

- The monolithic ribbon can be made without renting special equipment (although it is difficult to do without order of concrete). To collect the foundation from the FBS with their own hands, you will need to rent a crane, or at least the winch.

- If you do a monolithic foundation yourself, it costs it cheaper than block. If the hired workers or the firm work, it will cost, rather, more expensive: the volume of work is more, and these are considerable additional costs.

- Monolith is more durable than the national team. Strength is about 20-30% higher. This allows it to use a monolithic ribbon on loam and clay.

In many respects, the monolithic tape wins. But if its strength and reliability will not be in demand, then its manufacture is only in vain time loss. When working contractors, this is also a waste of money. Because the soils have a normal carrying capacity, and underground water is not closer than 2 meters from the required depth of the foundation, it makes sense to put the house on the national foundation.

Foundation Blocks: Types, Dimensions, Marking

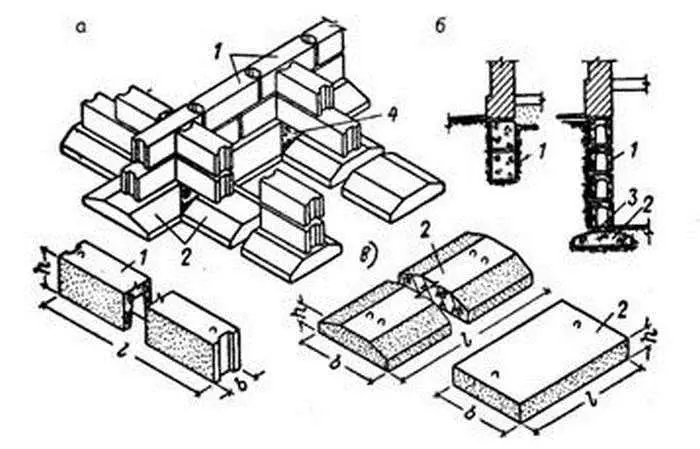

In private construction, several types of blocks are applied. For the device of the tape premium foundation most often use only two types:

- FBS is a foundation unit. Construction solid. When they talk about such a block of block, it is implied, reinforced concrete (with reinforcing) element without voids. These are rectangular blocks of different sizes, having mounting steel loops on the upper surface. Sometimes in the side of the sides, vertical channels are molded, which are flooded with a solution. Of these blocks, the foundation ribbon is folded.

- FL - Pillow blocks. Have a type of trapezium. Stay on the prepared ground and serve to increase the bearing capacity of the foundation.

Types of foundation blocks that will be needed for a collection of belt foundation

When erecting a belt foundation, it is necessary to provide tracks for laying and summing up engineering systems: water supply, sewers, electricity, heating. You must not forget about the ventilation system and leave the holes under the product to ventilate the underground space or basement. For this, blocks with a channel for laying communications can be useful: FBB.

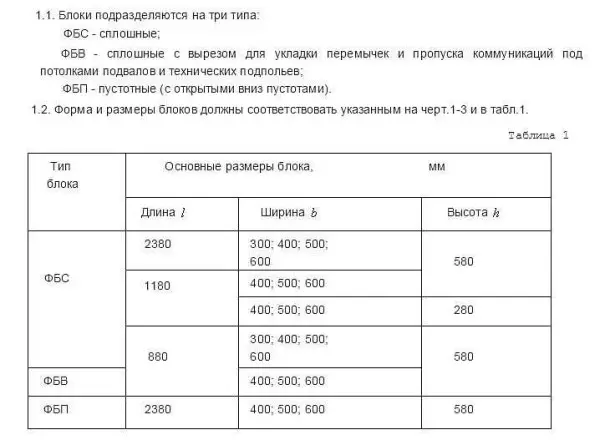

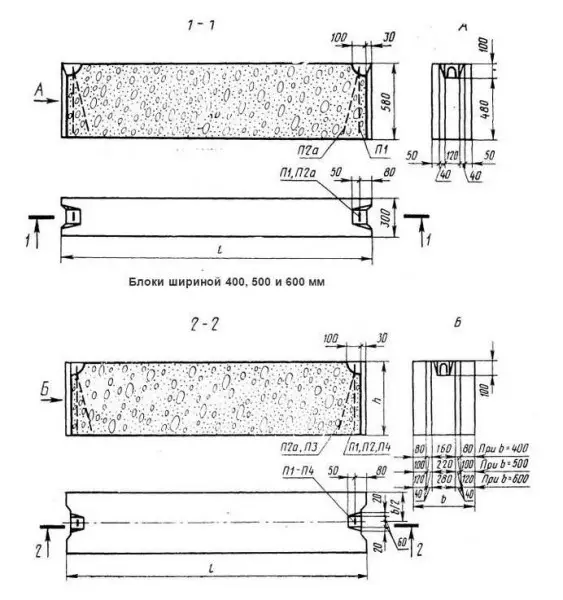

Dimensions and types of blocks are governed by GOST 13579-78. For a private developer, the size and operational characteristics are important. The photo below shows a part of the standard in which the types and block sizes are determined.

Exposure from the GOST, normalizing the size of the foundation blocks

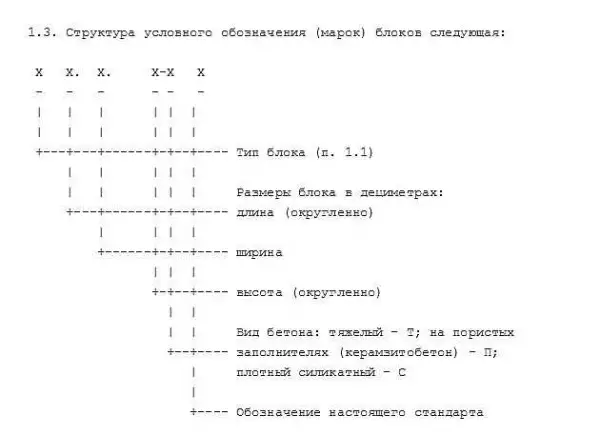

Marking according to GOST

To make it easier to navigate the specification, in the names of the blocks the same GOST has information about their size and type.

First talks. Next - figures describing geometry in decimeters;.

- first - length (9, 12,24);

- The second (through a dash or point) is width (3,4,5,6);

- Third - height (3.6);

Marking of concrete foundation blocks

If there are any length and width, the FBS height is usually 580 mm (in the label "6"). Make blocks with a height of 280 mm can be under the order.

Next, after the figures there is an alphabetic designation of the type of concrete:

- T is heavy (cement-sand mixture with rubble). The hardest high density unit. This type is used in the construction of foundations.

- P - porous with aggregate of ceramzitobetone. Have a smaller weight, but also less strength, also more hygroscopic.

- C - from silicate concrete (basic binder - lime). This type of blocks is afraid of wetting, because it is not used in the construction of foundations.

For example, FBS 24.4.6 -T is decrypted: a rectangular block of a high density reinforced concrete. Length 2380 mm, width 400 mm, height 580 mm. By analogy, you can decipher other designations.

Sizes of the FBS blocks according to GOST

Laying of FBS blocks

The choice of block width is due to the thickness of the walls located above. The length of the blocks is selected so that they occupy, if possible, the whole tape. But even experienced builders in the selection of blocks are mistaken: some unfilled areas remain, in which even the smallest elements do not become (they are called good). These sites are usually close to bricks on cement mortar. If the masonry turned out to be uneven, then it is plastering: it will be more convenient to apply waterproofing and insulation.

Typically, the collecting belt foundation consists of several rows of blocks. Their specific quantity depends on the required height of the tape. More often it is laid below the depth of the soil. Also taken into account the necessary height of the base.

Device block foundation. When laying blocks-pillows, some areas remain empty. They are concreted after installation

When installing the concrete blocks of any type, the same rule is used as when the brick is laying: the seams should not coincide. For this, they are placed so that the seam of the previous row overlap the body block in the subsequent row. The intervals (vertical seams) between standing next to the elements are filled with cement-sandy solution.

To give the design of greater strength and for a ligament of all blocks into a single system, fittings are stacked over each row. Depending on the type of soil and weight of the building, a rod class A-I - A-III is used. The number of rods is determined by the design when designing, they can be from 2 to 5 pieces. When laying and connecting the bar, all the rules of the reinforcement of the ribbon foundation are complied with the binding of angles, the simpleness occurs in the same scheme. The only difference is that the reinforcement belt is one. On top of the reinforcement belt, the layer of the solution is stacked, on it, with the displacement of the seams, the following blocks of blocks are set.

To find the foundation from the FBS with their own hands, it is reinforced

In compliance with these rules, the collection belt foundation will be durable and reliable.

We will build a foundation from the FBS with your own hands

The technology of building a national foundation, especially at the preparation stage, is not much different from other types: first digging the knob. The difference in the smaller labor intensity of the manufacture of the tape itself and is that it is not necessary to make a formwork.

Preparation of the base under block foundation standard:

- A fertile layer of land is removed, exported or stored on the site.

- Next comes markup. If a basement is provided in the house, a perimeter is placed if the basement is not - the tape is placed. Marking is made using pegs and cords. The tape is celebrated on both sides, denoting the width of the wall.

- Next are land work. Soil removed to the planned level.

- The bottom of the pit or trench is aligned and pre-tram.

When assembling blocks, do not forget to leave holes for engineering systems: Breaking the foundation is unacceptable

- The layer of sand or rubble is falling asleep and trambed well using vibroplites. Manual tamping will not give the required seal. Therefore, it is better to use vibrating plates. This is especially important if the carrying capacity of the soil is not very high. Such a simple operation, as a well-compacted sand-gravel benchmark, allows it to significantly improve.

- Two layers of waterproofing are stacked on the compacted base.

- Installed foundation blocks-pillows FL. They are laid out strictly horizontally. Check the correctness of the placement by the construction level or level. The gaps between them are filled with cement-sandy solution.

- The reinforcement is stacked, on top of the solution layer of at least 2-3 cm.

- FBS blocks are installed with seam displacement. No junction should coincide. The minimum displacement is 0.4 height of the block being displayed. If the FBS is using with a height of 580 mm, then the offset must be more than 240 mm.

- If there is another row of blocks, the Armopoyas is again laid and the solution on it.

- The blocks also exhibit with the displacement of the seams.

The number of rows depends on the necessary height of the base and the required depth of the ribbon. Performing the rules for laying blocks with ligation compulsory. Only so collecting the foundation from the FBS with your own hands, you will get a reliable basis for the entire structure.

How to lay the FBS

In any row, the laying begins with the corners. Then the blocks are displayed in the places of removal of semen. They are called beacon, and on them then equal all the others. The verticality of their exhibition is checked, corrections are made if necessary. Most often, the block must be raised again, move and put in place.

After the beacon elements are exhibited, the moisters are stretched - cords for which they are oriented when installing the following blocks. They note the boundaries of the wall, and so that the FBS stood symmetrically relative to the middle of the FL block (block-pillow). Maximum allowable deviation - 12 mm. All subsequent rows of blocks are also set to exhibit exactly above the middle.

When laying blocks, it is necessary to ensure that they fit one over the other without a big offset

Cords are more convenient to stretch in 2-3 mm from the side surfaces of the lighthouse blocks. It will be easier to exhibit. Intermediate blocks are exhibited from the largest: first put everything with a length of 2.4 meters, then 1.2 and then 0.9. The correctness of their installation is tested relative to the marking cords, vertically - plumb.

How to choose the size of the FBS blocks

Determine how many blocks you need to your foundation, you can by selection. You can do it on your own on the scale drawn on the scale. On the plan you are posting each block on the same scale.

Select the size of the blocks for the foundation from the FBS, based on the simple rule: to increase the strength of the design, you need to use the largest block sizes. Therefore, first draw the blocks of 2.4 meters installed in the corners, then, if they are placed, draw them in places of progress of simpleness. Between them, too, put the largest blocks that can fit there. Where they no longer become, put a smaller size. If some intervals remain in which even the smallest block (0.9 meters) is not placed, it is not enough - these gaps are filled with brick masonry.

Two types of prefabricated belt foundations from the FBS - with a pillow and without (fine-breed tape)

In the same way, draw the second row, not forgetting about the displacement of the seams. If necessary, in the same way draw the third one. Then you consider the required number of blocks of each size. The resulting plan does not throw away: it will be useful for you when installing the national foundation already on the site.

FBS Masonry Solution

For laying of foundation blocks, a standard cement-sandy M-100 brand is used. It can be obtained using different uterine cement and the amount of sand:

- On the 1st part of the cement M300 take 2.5 parts of the sand;

- On 1 part of cement M400 sand is already 3 parts;

- When using the sand M500, 4 parts are packed.

First mix dry components before receiving homogeneous composition and color. Then 0.5 parts of the water are gradually added. If the solution is obtained too thick, the water gradually agitated in small portions. The consistency should be like a thick sour cream: not lump, but not to flow.

Do not try to increase the number of cement. This will not only increase the strength of concrete, as you expect, and it will be much reduced. To set the fortress of concrete, it is necessary for a strictly defined amount of the filler (in this case of sand) and water. With the lack of that / or other, its strength will be lower. In the worst case, he will crack and crumble.

Article on the topic: Curtains for giving with their own hands - simple options