Durable and solid concrete requires protection from the impact of natural factors. Depending on the composition, it absorbs up to 10% moisture. Frost converts water into solid crystals that destroy the walls from the inside. Paint on concrete for external work creates a barrier from the penetration of water that destroys the action of the sun and wind. With a limited budget painting of walls and a walkway on the street it is better to make it yourself, but do not save on the quality of the material.

Paint on concrete

Solid concrete needs protection

The next stage of finishing works has led a friend to me for advice and help. Vadik was interested in how to paint concrete outside and inside with their own hands. What is the difference between materials for walls, tracks and floor in the garage. What a wash will help to remove the old paint and the dirt has emerged. He already knew that the concrete was produced epoxy and polyurethane paint for outdoor walls in the house and on the street. What appeared a rubber mixture other than latex.

Paint on concrete for outdoor work

Concrete is solid, does not react to aggressive acidic and alkaline solutions. It is able to withstand large static loads. Weak part of structures from cement solutions is low resistance to mechanical effects. The concrete wall can be easily scratched with a metal object. Even the usual shoes with intensive exposure erases the floor surface. Blows lead to the formation of cracks.

The sun and wind are also not friends of concrete. In winter, frost turns moisture inside into the ice and destroys the walls and tracks from the inside. Paint is needed to protect the concrete surface. It must have certain characteristics:

- High adhesion - adhesion with concrete.

- Good shelterness so that one layer is enough to cover the surface.

- Hydrophobicity for repulsing water and protection against rain and dampness.

- The plasticity allows the paint to expand and deform when the temperature changes along with the wall.

- Abrasion resistance will extend the service life of the floor and tracks in the zones with active operation.

Paints on concrete have different characteristics. The main among them is the grip. Cement solutions are poorly connected to many finishing materials.

The main thing for finishing materials - adhesion

Independently paint on concrete

Article on the topic: how to install an acrylic bath

Manufacturers offer various paints. They have their drawbacks. Quality and durable compositions are expensive. They fully pay for the service life and the ability to paint concrete with their own hands. Exemplary characteristics To select my friend gathered in the table.

| Paint | Coating M2 liter | Number of layers | Application | disadvantages |

| Oil enamel | 3 - 4. | 2. | Walls inside and outside | short-lived, strong smell, burns out, does not let the air |

| acrylic | 3 - 4. | 2. | Walls inside and outside | Low vapor permeability |

| Silicate | 4 - 5. | More than 3. | For external work | Bad hiding, it is necessary to apply several layers |

| Silicone | 4 - 6 | 2. | For interior and exterior use | high price |

| Latex | 6 - 9 | 2. | For internal work | Does not tolerate negative temperatures, on the street can be used in southern regions |

| rubber | 4 - 5. | one | Universal | high price |

| Epoxy | 3 - 4. | one | for floors and outdoor walls | The complexity of the preparation of a two-component composition |

| Polyurethan | 12 | one | Self-leveling floors | The complexity of cooking is not suitable for walls |

Classic option to paint concrete walls - oil paint. It costs cheap, repels water. Walls in residential buildings can not be painted, because the film formed after drying does not pass the air. Enamel quickly begins to crack and remove it difficult. Washing only softens it, it is necessary to remove the spatula.

Epoxy enamel water-based wear-resistant. It is used for walls and floors inside the building and to protect facades, sites, tracks and concrete structures of bridges, power lines, outside. It is easy to apply with your own hands, used in all regions, frost-resistant. It is advisable to produce painting at temperatures above 5 degrees.

Stages of surface preparation to new staining

Paint for outdoor concrete work

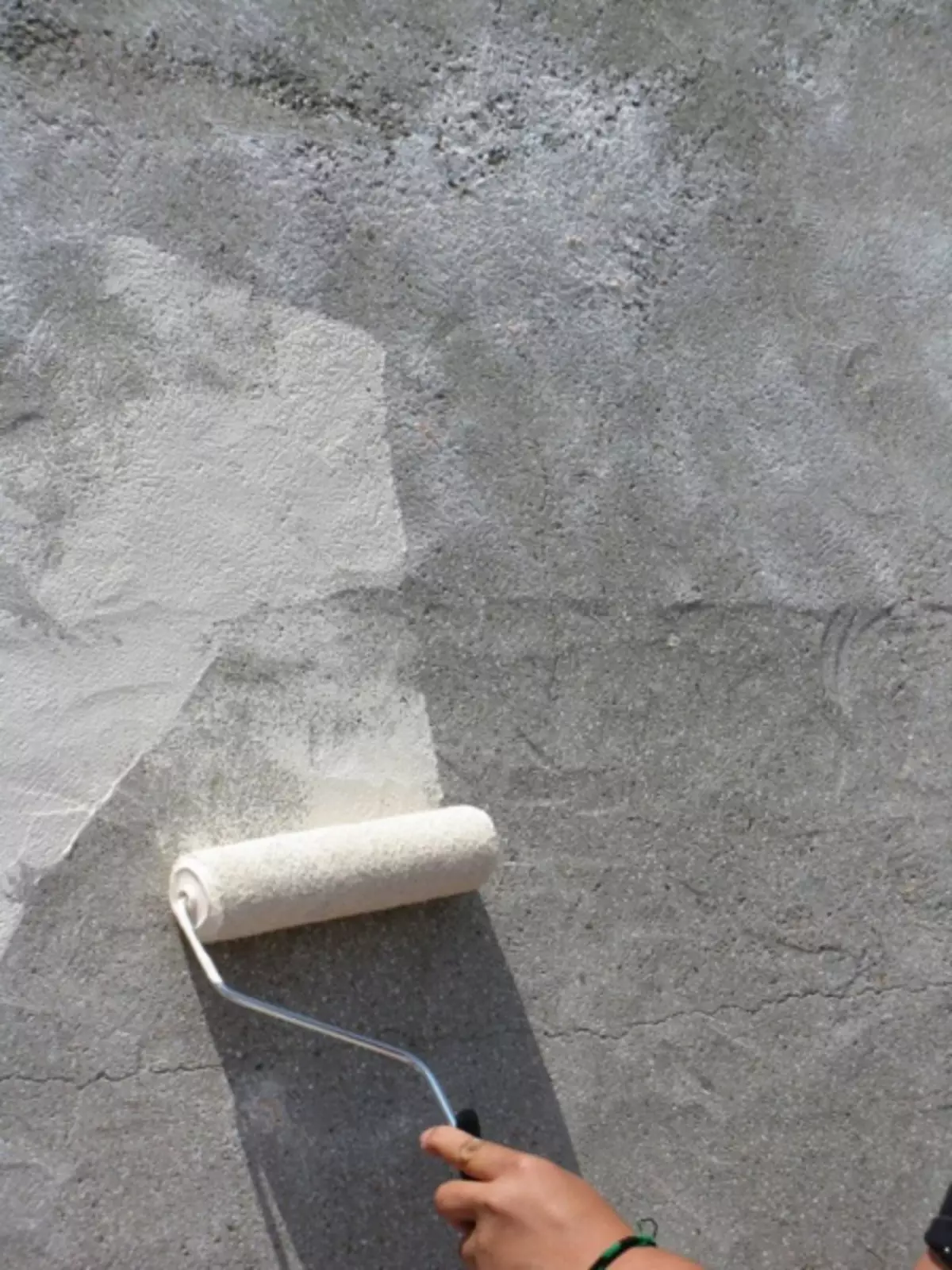

The surface of the frozen cement mortar is porous with poor adhesion. Before painting the concrete floor and the walls with their own hands, you need preparation. Fresh flooded solution should stand at least 30 days. Then it can be prepared under painting.

- Remove all dirt from the surface.

- Clear paint residues.

- Washing is used for final purification from dust, dirt, fat spots.

- Sharpen potholes and cracks.

- Cover all primer. The choice of material is made according to the type of paint that will be applied.

- Painting of concrete floor or walls according to the instructions on the selected finishing material.

Everything can be done with your own hands. It is only necessary to remove all the dust to ensure adhesion and give the surface to dry after each operation.

Vadik removes old paint and applies washes

We select paint on concrete

Article on the topic: how to sew a lambrequen fan: tailoring with your own hands

Preparing walls and gender in the old garage under painting, Vadik tried with their own hands all the common ways. He began with my feed from the most laborious and reached simple:

- mechanical with the use of grinder and nozzles;

- thermal with local heated;

- Chemical using washes and solvents.

At first my friend used the petal circle about the metal brush. He scratched the coating layer, sometimes together with the cement. At the same time, the cloud of dust rose, and physical strength was required. The ability to operate the power tool at Vadik was. He defended his eyes with glasses, dressed a mask.

Tip! Moisten the processed area with water from the sprayer, dust will be less. Only do not pour a lot.

I became a pity stubborn friend. I brought him a metal spatula and a construction hairdryer. Now he heated small pieces of old finish and filmed it softened. The part of the composition burned out, highlighting caustic smoke. Therefore, he did not remove the respirator.

After time, Vadik surrendered. He recognized this method good for work in winter. In summer and so hot.

I brought a pre-purchased liquid from the car. Washing is selected paint. It is applied to the surface and, entering into a chemical reaction, softens the paint. Sometimes you have to delete everything for several techniques. Metal spatula and respirator in this case are necessary. The strong smell of the solvent can damage the breathing organs. The softened material you need to remove the solid blade.

Parry permeability and moisture resistance are important for exterior walls.

Pray on concrete with your own hands

Paint with certain characteristics is selected for finishing the facade:

- good adhesion with concrete;

- pushes water;

- passes air.

From materials used for exterior walls, popular:

- silicate;

- silicone;

- acrylic.

Enamels are short-lived. They are difficult to remove before the next painting. The walls are not breathing beneath them, and the microclimate inside the house is disturbed.

For tracks in the courtyard and parking spaces, frost-resistant and wear-resistant paint fit:

- epoxy;

- polyurethane;

- rubber.

It creates a solid solid film, resistant to erasing and physical destruction. Well pushes water and protects concrete. Washing to remove it upon subsequent repairs, selected by the type of composition, and remove the old paint with a chemical method easily with your own hands. For a mechanical method, remove the coating by these water-soluble mixtures is difficult.

Rubber floor paint

Paint for outdoor concrete work

Rubber paint represents a complex composition on an acrylic basis with additives from silicone and other components. Water-soluble, with good shelterness, it appeared recently and is used mainly on the metal. It is easier to buy in a car store in the canister, since the owners of cars like her matte, similar to rubber, surface.

Article on the topic: What wallpapers fit to dark furniture

Painting concrete floor rubber paint gives the room a stylish look. Important are the properties that it gives the surface:

- Resistance to moisture and chemicals;

- prevents slipping;

- absorbs noise;

- environmentally harmless;

- You can pick up bright colors for every taste.

Rubber paint is suitable for walls. It is easy to remove with your own hands when preparing for a new finish. Washing acts effectively and does not have a strong smell. Vadik was interested in how to paint the concrete floor in the house and in the courtyard. I advised him a new composition. In buildings, rubber paint covers concrete floor of balconies, gyms, utility rooms, paths and sites on the street.

Painting of walls indoors

In addition to those specified in the table, the walls inside the house can be coated with water-emulsion compositions for concrete. It is necessary to remove all the dirt and dust from the surface, cover all the primer deep penetration and wait for complete drying. Washing on the walls is applied several times, since it flows, without having to penetrate deeply.The walls of the garage, the storeroom, the boiler room will protect epoxy paint. It performs simultaneously and primer functions. The complexity of its use in the preparation of a mixture of two compositions. The surface is thoroughly prepared. To remove the dirt remnants, use a special wash. It is necessary to follow the instructions and proportions specified on the package.

On the floor, scream legs, knock the heels and drop burning cigarettes

Paint on concrete

Old paint take off the floor with your own hands easier than from the wall. Washing does not flow, and over time softens the surface without additional application. Cleaning from residues of chemicals and dirt is the most convenient jet of water under pressure directed from the hose.

The main destroying effect on the floor is:

- Feet of people erasing the surface when walking;

- In offices and public premises, the pressure of thin heels - studs;

- Heavy furniture creates statistical pressure;

- Visitors can drop heavy items and burning matches and cigarettes.

Of all the paints on concrete qualities that satisfy all requirements, possess:

- epoxy;

- polyurethane.

Both compositions can be applied with rollers and paintopult. Epoxy enamel is prepared from two components immediately before applying. It is difficult to remove it, but you can apply the following layer with similar components after cleaning the surface from dirt.

Polyurethane composition is used for staining and creating bulk floors. Corrence when buying in the store or before use.