Formwork is a design of shields, struts and stops, which serves to give concrete and reinforced concrete products. If we talk about construction, then this system is necessary when filling the foundation of any type, but the largest designs are needed when the constructive monolithic foundation is installed. Apply formwork and when creating reinforcing belts in the masonry of walls from building blocks. In the same buildings, the reinforced belt is often needed to create a solid base for fastening the roofing system. It is formed by the help of formwork. We need this design and when pouring concrete tracks or concreting of the scene, with some other types of work.

Removable and non-removable

According to the principle of use, the formwork can be removable (collapsible) and non-removable. As it is clear from the name, the removable understands the concrete gains strength above the critical (about 50%). Therefore, it can be used several times. Depending on the material, the same kit can withstand from 3 to 8 fills, industrial options can be used by several dozen, and some - hundreds of times.

Removable formwork dismantled after concrete scored 50% strength

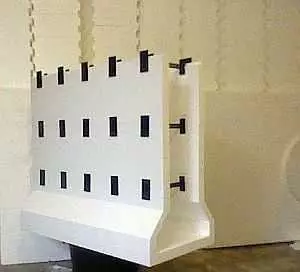

Failure formwork becomes an inhabitual part of the foundation. Such systems began to use relatively recently. Make them mainly of extruded polystyrene foam. The blocks of different configurations are produced, which are connected with the help of locks and metal studs. From the blocks, as from the designer, the necessary form is recruited.

Failure formwork becomes part of the foundation - it is also a part-time insulator

The non-removable polystyrene formwork not only gives the form, but also at the same time is heat-hydro insulation, also has sound-insulating properties. It is worth it a lot, but immediately solves a lot of problems, and the time spent on the foundation device is significantly reduced.

There is another type of non-removable formwork - hollow concrete blocks. They also have different configurations - wall, angular, with radius, etc. Consist of two or three walls and several jumpers, holding the walls in a certain position. Compared with each other with locks, reinforced with rods.

Requirements for formwork

Since the whole system is created to give the shape of concrete and reinforced concrete products, it must be sufficiently durable and elastic to resist the pressure of the mass of liquid concrete. Because the materials for formwork are presented quite serious requirements for the part of the strength. In addition, the collected shields must have a smooth and smooth inner surface: it forms the walls of the foundation, and the hydro and / or thermal insulation materials are then fixed on them. Fix them easier to smooth (at least relatively) surfaces.Materials for removable design

In construction organizations, there are metal structures collected on studs and bolts. In private construction, formwork shields make from boards, moisture resistant plywood and OSP. Wooden bars are used as stops and spacers. No one bothers to make a metal design, but it is very expensive and in one-time use is unprofitable.

During the construction of the cottage or country house, the boards made of boards are most often used. The breed can use any, and coniferous, and deciduous. It is better to take edged: a solution should not be covered through the formwork, and it is impossible to achieve this with an unedged board.

What does formwork look like for a ribbon foundation in the context

With a foundation height, up to 1.5 meters, the formwork board should have a thickness of at least 40 mm. Shields are fastened with a sections of 60 * 40 mm or 80 * 40 mm brucks. If the foundation height is big - it is deep downhill - such bars will not be enough to keep the mass of concrete. With a height of more than a meter, you need to use a bar 50 * 100 mm and more. For assembly, nails or self-tapping screws are used. Their length is 3/4 from the total thickness of the board and the bar (for the size above 60-70 mm).

Article on the topic: Decor of the old door with their own hands: Stained glass window, decoupage, cracker (photo and video)

Make formwork and plywood. There is even a special formwork, laminated paper with synthetic impregnations. The coating has increased resistance to the aggressive medium, which is liquid concrete. This material FSF is labeled (using formaldehyde glue).

Plywood thickness for formwork - 18-21 mm. Shields are collected on a metal or wooden frame. Wooden frame made from bar 40 * 40 mm, fasteners need to use shorter - 50-55 mm. When using plywood, it will be easier to work with self-drawing: nails are clogged hard.

Construction of formwork shields from plywood and OSP

OSB is used for this purpose infrequently, but this option also takes place. The thickness is about the same: 18-21 mm. Structurally does not differ from plywood shields.

The dimensions of these sheet materials are selected based on the dimensions of the required formwork shields - so that the waste is as small as possible. Of particular surface surface is not required, therefore you can take low-grade materials, which are usually called "construction".

What makes the formwork for the foundation decide to decide: depends on the prices of these materials in your region. The usual approach is economic: what is cheaper, then use.

Formwork for a ribbon foundation with your own hands

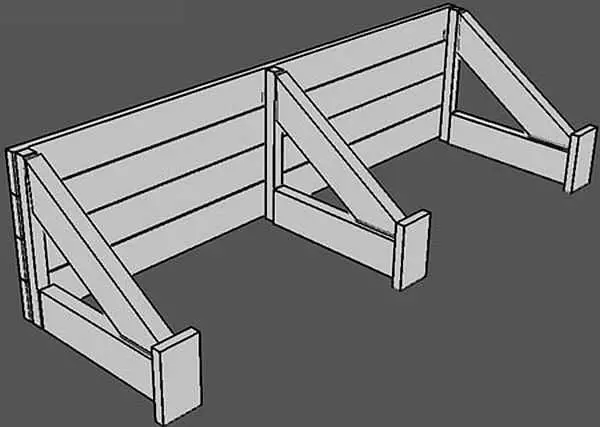

The most voluminous - formwork for a belt foundation. She repeats the contours of the house and all carrier walls from two sides of the tape. When building a more or less large building with a large number of partitions, the consumption for materials for the formwork of the foundation will be very significant. Especially with the deep attachment of the funldament.The design of the shields and their connection

When assembling the formwork, it is important to make shields durable: they will need to keep the mass of concrete until the cursing occurs.

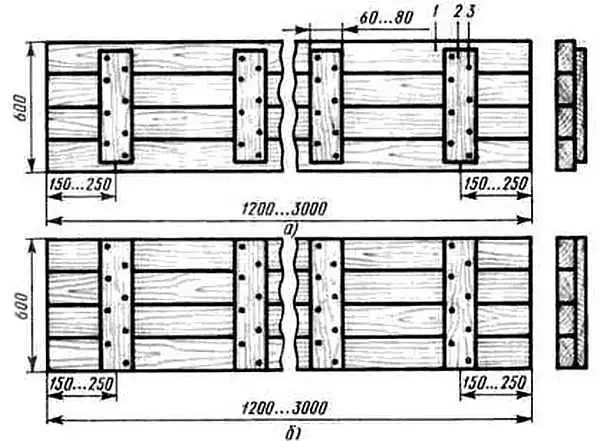

The dimensions of the formwork shields are changing and depend on the geometry of the foundation. Height is slightly higher than the foundation height, the length of each shield is determined by themselves, but usually it is inconvenient from 1.2 to 3 m. With very long structures, it is inconvenient to work, so that the optimal length of about 2 m. The total length of the entire formwork should be such that They became accurate on the markup of the foundation (do not forget to take into account the thickness of the shield).

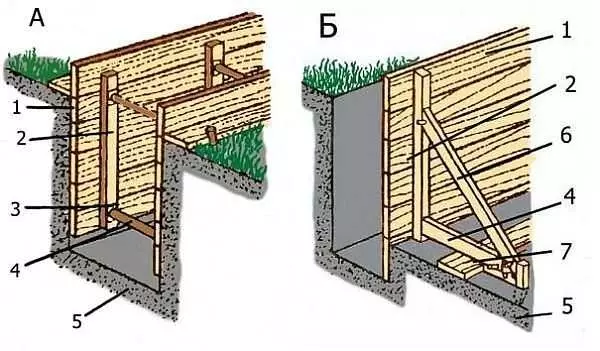

How can a formwork for a ribbon foundation can be installed: tape tape died in dimensions and in downtown

In the manufacture of formwork from boards, cut several pieces of the same length, fasten with bars and nails or screws. When using nails clog them from the inside of the shield, bend on Broke. With self-drawing, it is easier to work: they do not need to bend, since they provide dense adjacent elements due to threads. They are tightened from the inside of the shield (the one that will be addressed to the wall of the foundation).

The first and last bar are attached from the edge at a distance of 15-20 cm. Between them, at a distance of 80-100 cm, put additional. To install formwork shields, it was convenient, two or three bars (along the edges and in the middle) make a 20-30 cm longer. They are sharpened and when installing are scored in the ground.

Approximate cutting board shields

Shields from plywood or OSB are collected on the frame from Bar. When assembly, it is important to strengthen the corners well. In this design, they are the weakest place. You can enhance them using metal corners.

Installing formwork with your own hands

If the shields made with several elongated bars, they need to be set on the tensioned marking cords. The complexity is that at the same time it is necessary to exhibit in the vertical plane. For fixing, you can use the scored by the mark and the verticals of the bars. When the shield plane is installed close to these bars. They will be support, and guides.

Article on the topic: Installation of window sills and slopes on plastic windows

Shields with elongated transverse bars set easier

Since the bottom of the trench or the pit should be even (compact it and level it under the level), then put horizontally shields should be simply. Try not to score them hard: it will be easier then to align. Lower one of the corners to the level of the submetock. The slots should not be, the solution should not flow. Having achieved a dense fit, take the construction level, apply along the shield and hammer the second edge until the top edge is installed horizontally. The next shield is already set about the established: they must be at the same level in the same plane.

If the shields are made without long bars, on the bottom of the pit, along the line marking ribbon, the bar is fixed, which will be emphasis. Shields are attached close to it, then with the help of voids and struts are fixed.

Strengthening - Splits and Stop

In order to under the mass of the concrete, the formwork does not fall apart, it must be fixed outside and from the inside.

Outside set off. The backups must stand at least than through the meter. Special attention should be paid to the corners: there are stops in both directions. If the shield height is more than 2 meters, then one belt stops not enough. In this case, there are at least two tiers of struts: upper and lower.

Outside, formworks put stops and disclosures. At high height, they are made in several tiers. Pay attention to the thickness of the support bar

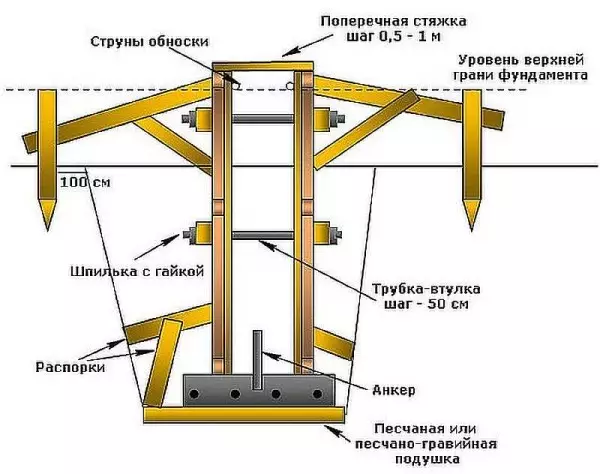

It is necessary to stabilize the distance between two opposite shields. For this purpose, stiletts from reinforcement with a diameter of 8-12 mm, gaskets made of metal and nuts of the corresponding diameter. Studs are installed in two tiers: at the top and bottom, at a distance of 15-20 cm from the edge.

The length of the studs are larger than 10-15 tape width. There are two options:

- In both ends of the reinforcement, thread is cut. Then the two metal sealing plates and nuts will be required for each stud.

- On the one hand, the pin is bend and flattened, a thread is cut with the arc. In this case, the nut is needed one (the plates are still two).

The internal distance between shields equal to the design width of the tape is fixed using segments of plastic pipes. Their inner clearance should be a little more rapid thickness.

How to make space splashes in formwork

The assembly occurs as follows:

- In both shields, a long hole drill is drilled.

- Between them is set to cut pipe.

- Stiletto has been doing.

- Metal plates are installed (they will not allow the hairpin to break the shield material).

- Nuts are twisted and tightened.

You need to work together, and better - threesome. One inside between the shields installs the tubes, and for the person to install the spills and twisting of the nuts.

When removing the formwork, first spin nuts and remove the hairpins, then dismantle the slopes and stops. Freed shields are removed. They can be used further.

How to spend less

A lot of material is leaving for the manufacture of formwork for a tape base: shields form the entire tape on both sides. With great depth, the consumption is very large. Let's just say: it is possible to save. Make only part of the formwork and upload not all in one day, and parts. Despite the widespread opinion, it will almost not affect the strength of the foundation (if you know the secrets), and you can save it decently. You can share the foundation or horizontally, or vertically.Fill layers

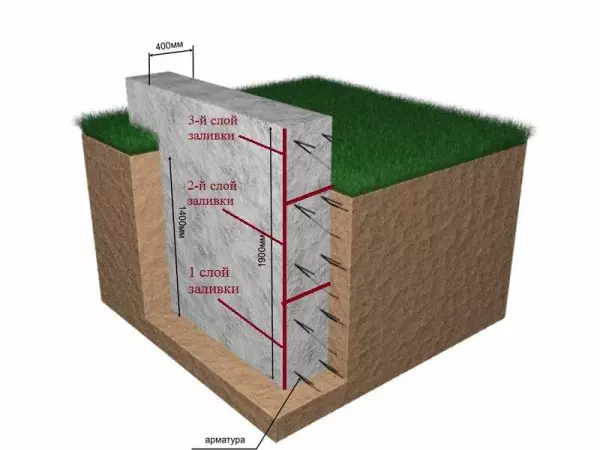

With a big depth, it is more profitable to make fill with parts horizontally (layers). For example, the required depth 1.4 m. You can smash the fill into two or three stages. At two stages, it will be necessary to make shields with a height of 0.8-0.85 m, at three - 50-55 cm.

If the foundation has a greater depth of climbing, it can be poured in two three parts, separating vertically by approximately equal shares

The order of work is:

- A formwork is exhibited from the short shields made, fittings fit on the entire required volume.

- Concrete is poured in height of the formwork made.

- After 7-8 hours after the fill, it will be necessary to take the top layer from the entire surface of the ribbon. When breeding concrete, cement milk rises up. Thorough, it becomes fragile and brittle. It is this layer and you will need to delete. As a result, the surface will be uneven and rough, and this will improve adhesion (adhesion) with the following layer of concrete.

- At a temperature of + 20 ° C, three days later, the formwork can be removed, clean the shields and secure them above. Removing shields, take out the hairpins. Pipes can be left in concrete. They have already become part of monolith. Sometimes they are taken out, and the holes are filled with mortar.

- Expose formwork above and pour again.

The shield is simply installed on the already "grab" concrete, and rests on the edge of the trench, but already on the other level

When installing the second (and third, if necessary) the tier shields are slightly found on the already flooded area, covering the tape from the sides. At the same time, the bottom row of studs usually serves as a stopper and emphasis. Therefore, when they are installed, put them all on the same level from the bottom edge of the shields.

Armature is already connected, the internal studs are cut. It remains only to put other tubes to return to the place of the hairpins and put out the external stops and disclosures. Time to install the next layer of formwork is not so much.

Why does such a way affect the strength of the foundation? Because when calculating the strength of concrete is not taken into account. She goes to "stock." In addition, the load in ribbon foundations is distributed along the long side. And in the length we have no breaks. So the foundation will stand for a long time.

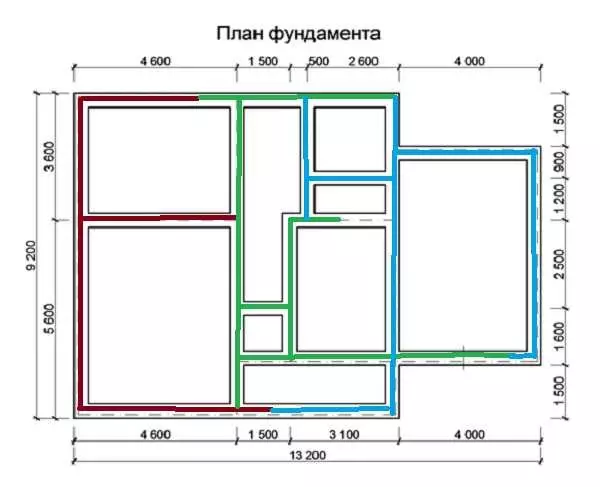

Vertical division

The second way is the breakdown of the vertical plan. The foundation can be divided into two or three parts. Only you need to share not exactly "along the line", but disseminate the joints for a while.

In the building selected for the installation, you install the formwork with "plugs" in those places where the installed part ends. Inside the installed part knit the reinforcement frame. At the same time, the rods of longitudinal reinforcement should go beyond the formwork at least 50 diameters of the reinforcement used. For example, a rod is used 12 mm. Then the minimum release beyond the formwork will be 12 mm * 50 = 600 mm. The next rod is tied to this issue, and one after another they will enter these 60 cm.

One important detail: breaking the plan of the house in parts, make it so that the "pieces" fill up during this period at different levels (see in the picture).

The second way is to divide the plan for several sites (in the figure they are marked by different colors)

Pour the collected section of concrete. As in the previous method, after 7 * 8 hours it will be necessary to climb the solution, but already on vertical surfaces. We take the hammer and removing the sidewall-plug, get the cement-sandy solution to the rubbank (near the formwork will most likely be a layer of a solution without a placeholder). As a result, the surface will be shrumbat, which is good for clutch with the next portion of the solution.

These methods can safely be used in private construction: they are practiced in the construction of monolithic multi-storey houses, and there are workers on concrete walls and the foundation is incomparable.

There is another trick. Everyone says that boards or phaneur can then be used in auxiliary work. In practice, it turns out differently: it is impossible to cut into the cement in the cement of wood or Phaneru. In addition, it becomes dirty and rough, and it is also impossible to clean and polish it: no grain "does not take." So, so that wood (and plywood, if non-aluminated) remains suitable, the front of the shields are tightly tightened. It is fixed with a construction stapler and brackets. If it is damaged, the replacement takes quite a bit of time. The formwork enhanced in this way gives an almost perfectly smooth surface of the foundation, which facilitates the subsequent work on hydro and heat insulation.

Article on the topic: Suspended aluminum ceiling ceiling