Warm floors are used very wide. They are convenient because the legs are always warm, which means there will be no freezing of the body and disease. This system of heating every year is still used more and more. People prefer precisely this type of heating.

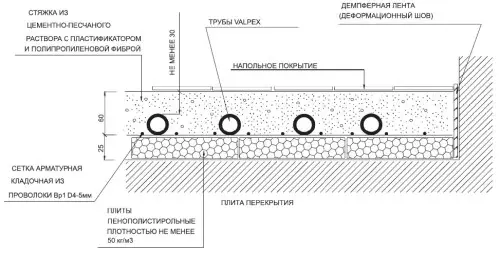

Pie scheme

Definition

The warm-alone device is one of the types of heating. Why are they very popular? Because the main secret is heat transfer with a plate, which consists of natural or artificial materials. Infrared radiation is created, which fills the space and warms it. Cake is performed only on the screed. The screed is a concrete layer with which "Pie" begins. The screed can be made in such ways:- Use cement, sand. These components must be mixed. The next step is the addition of PVA glue. The ratio of components - 2: 2. That is, 2 liters of adhesive will take 2 liters of cement-sandy solution.

- With the help of special solutions that manufactures enterprises. In this case, it is possible to install the water heating system. Installation of electric mats is also possible, and infrared floors are not made under the tie.

Pole Pie

Warm floor laying schemes.

You need such materials:

- Heat insulation materials. It is necessary to have polystyrene foam mats. If the load on the floor is large, then the plates are used, which includes extruded polystyrene foam.

- Need damper tape. Its thickness is not more than 1 cm.

- The presence of reinforcement grid will strengthen the concrete component. This grid can also do the installation of the heating pipe.

- The presence of metal-plastic pipe. It is possible to replace metal plastic on polyethylene.

- Pipes are fixed using brackets, mounting and rotary arcs.

- Concrete solution.

- In the concrete solution, you will need to add additional ingredients - plasticizer and filler.

- Collector system (comb). The presence of this system is necessary in order to connect the floor circuit.

Article on the topic: Detached Bath: How much does it cost?

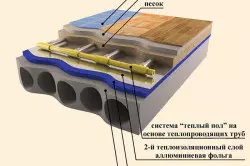

Installation is done on the old basis. Thermal insulator is installed on top (for this it is necessary for the presence of foam / foil plugs). These components are mandatory components for mounting, whether water or electric floors.

The next step will require the installation of water pipelines, cables and heating mats. At the end there is a screed concrete. As a result, the cake is obtained.

In this case, a concrete screed must be laid out strictly in such a cake of a warm floor on a soft material.

When installing, it is necessary to lay thermal insulation material on the preliminary screed. For durable stops of two screeds (especially for rooms, where the small area of the perimeter) of the heating floor, you need to make holes for each square meter (insulation area).

Warm floor concrete screed circuit.

Across the area of the room where the pie is made, it is necessary to leave about 12 cm of open space in the form of a strip. This will create an emphasis for both screeds. It is noteworthy that thermal insulation in the cake has another feature - sound insulation. The screed must have a thickness of 4-6 cm. No less and no more. This is the optimal indicator. Moreover, such a thickness is optimal and does not depend on the characteristics. This will provide the balance of heating surfaces, as the cold and warm stripes will be alternate. If for some reason you need a screed of a smaller thickness, then adding a universal plasticizer to the cement solution. On 200 g of the solution is added 2 liters of added mortar.

Stages of performance

You need to install insulation on the black screed. In order for the insulation to be dismissed from the spot, it is better to fix it. For fixing, you can use tape, glue or dowel. On top of the heat insulator, it is necessary to put a metal grid. This mesh other than the reinforced function performs a marking, when the pipeline, cable systems and films are locked.

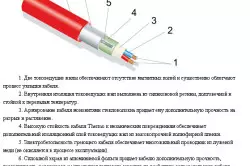

It should be noted that it is not necessary to use personal and expensive cables to connect the system.

Article on the topic: Antistatic Linoleum Stacking Technology: Main Stages of Work

The diagram of the heating cable device.

The grid must be copped with the base. Throughout the area where the pie is installed, you need to stretch the damper tape. This is a heat shrinking stripe. It is done in case of incorrect or erroneous installation, that is, if some invisible errors are made, which can lead to a failure of the system. To compensate for the thermal expansion of the screed and stacked such a tape. Among other things, this tape performs a soundproofing and thermally insulating function. When laying a damper tape, it must be borne in mind that it needs to be laid in two layers. Let it be thinner, but in two layers, so she envelopes all the irregularities. In the future, the cement solution will be poured into this layer.

In order for the particles of the solution, they do not get into the previous layer, in front of the concrete layer you need to put a polyethylene oilcloth. It will serve as a waterproofer, because when the solution inserts, cold bridges will be formed in the seams of polystyrene foam, which can only be corrected only by reworking the cake system.

All components of the warm sex are installed and attached to the coolant. Then the last concrete screed of the warm floor occurs. After drying, there is already an outdoor coating. Connection and connection can be carried out only after concrete freezes. If problems are detected in the device or it does not work, the cake will need to break and install all over again. Therefore, detailed and consistent execution is very important.

So, summing up, you can list which layers are present in the cake. If you count from the bottom, the very first is crushed stone and sand, the second is a film (polyethylene), then a rough screed goes. The fifth layer consists of waterproofing material. Next is the insulating layer, which is covered with a pure reinforced tie, the decorative layer is styled upstairs - this is a flooring. Of these layers, a cake of a warm floor is created.

Article on the topic: Liquid putty for walls - what is it?

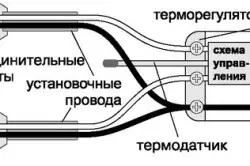

Warm floor connection circuit.

If the cake is installed on the ground, then the ground is added to the lower layers. To install a warm floor to the ground, follow the following processes. The soil must be dry. Then the flooring will not become a difficult task. If the soil is wet, you need to wait for it to complete drying. Geotextiles will be stacked on the ground.

The next layer of the cake will be a 15-centimeter layer of rubbank. Geotextile in this case plays the role of the barrier so that rubble is not accumulated in the ground. Crushed stone plays the role of the barrier from the capillary moisture supply from the soil up.

The next layer will be sandy, but in order for it not to wake up, you need to put another layer of geotextile. The sand is necessary as much as possible. It is done manually, without the use of label machines. They can change the relief of the layers, and it is impossible to allow. It is necessary to catch up so that all the layers do not breathe to sand. "

Next comes the reinforced screed, which was described above. The layers of concrete, pressing on all the rest of the cake layers, will wipe them. It is important that air cushions do not arise. Sand sends, so you need to ram it more than once, constantly looking through the pillows. Before installing the cake, you need to check the sewer pipes. In order to avoid moisture, the pipes are sealed with fiberglass coupling. It should be a hermetic coupling that will enaches the clamp.