Hood for boiler in its own private house

The owner of a private house in most cases faces the issue of maintaining a microclimate in all available rooms, that is, their heating.

The service life of steel extracts is much less than brick and ceramic.

Heating household systems are made to distinguish with the type of fuel that is used:

- Solid fuel (firewood, coal);

- Gas (liquefied or natural gas);

- Liquid (diesel fuel).

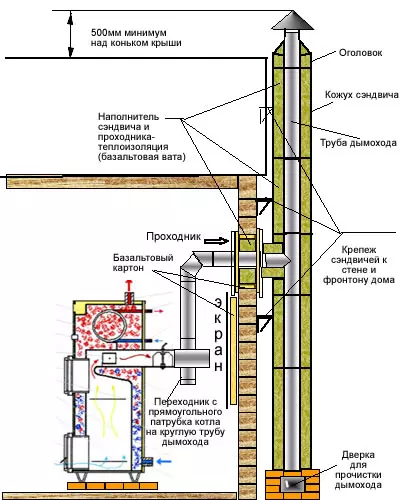

Ceramic chimney scheme for boiler in a private house.

Scheme of the heating of a private house with a boiler.

All of them unites the principle of obtaining heat - the process of burning. In order to maintain the combustion process, you need oxygen. In addition to the greater power, the boiler has, the more surrounding air it will be needed for work. Solve the issue with the arrival of the required amount of air to the boilers is designed to exhaust the boiler house of a private house.

To date, there are 2 ventilation systems - forced and natural.

Natural ventilation lies in open windows, the presence of gaps is at least 2 cm between the doors and the floor, the ventilation pipe in the area of the bathroom ceiling, which leads out through the roof of the house, artificial draft.

Forced ventilation can be both inlets and exhaust. In all cases, the air duct has a fan, which will drive the air into the house or from it.

In order to organize the ventilation of the boiler house of a private house, both systems can come up, but there is one fundamental difference:

- With natural ventilation, you will need to organize air inflow directly in the boiler room. At the bottom of the wall for this (most often opposite the boiler), a through hole is made out. The diameter of the duct is selected commensurate boiler power from 150 mm and more. Air intake is regulated by a saiber (valve), which is located on the decorative hood grid. During the operation of the boiler, like a vacuum cleaner, it will pull the air in the furnace, while not creating any discharge in the boiler room.

- It is not allowed to place an inflow part of the forced ventilation in the boiler room. In this case, it is necessary to proceed from security reasons. In the case of a possible failure in the work of the boiler, combustion or gas products can be separated throughout the incoming intake air.

The hood in the boiler room will benefit. It can create an additional movement to the air boiler. In addition, it is an insurance in case of unforeseen circumstances in the work of heating equipment.

In private new homes that are equipped with heating boilers, in order to divert the flue gases, in most cases traditional brick chimneys are used, and more and more often people begin to use ceramics and steel hoods.

Hood from bricks for solid fuel boiler in a private house

Brick exhaust scheme for solid fuel boiler.

Brick tube in most cases costs cheaper than the modern chimney system. The traditional pipe hood tube is able to easily withstand high leakage temperatures. The pipe can even withstand the fire of soot clusters.

The brick extract for the boiler in a private house is a rather difficult structure. The hood is located on the foundation or durable overlap from reinforced concrete. The construction of such a design requires some specific skills, because the toggage of the durable and hermetic exhaust is recommended to charge a highly qualified mason of the Pechnik.

Article on the topic: Door closer with your own hands: How to make and install?

Rough hood walls will contribute to the accumulation of solid particles of soot on them. The rectangular shape and roughness of the channel wall make it difficult to clean the drawing from various sediments.

The brick hood for a long time and reliably serves solely at a high temperature of exhaust gases, which is able to prevent the formation of condensate in the pipe. This condition in most cases is performed when the exhaust is made with an ordinary solid fuel boiler.

In the process of working with modern boilers on liquid fuel or gas, as well as with pyrolysis solid fuel boilers, pellet and some others, which for a long time work in the mode of slow combustion of low intensity, the brick extractor is quite quickly destroyed.

Modern boilers are designed so that the exhaust gases have a fairly low temperature. In the chimney, the result is condensation of water vapor, which are contained in flue gases. Pipe walls will be constantly moisturized. In addition, water, connecting with the rest of the combustion, will form aggressive chemical compounds on the inner surface of the pipe.

In the outgoing gases of the boiler, it contains sulfur that interacts with water will be in the design to form sulfuric acid. Similar acid is able to destroy the walls of the exhaust. External signs of destruction - wet dark spots on the outer surface of the brick pipe.

The mode of operation of the pyrolysis solid fuel boiler contributes to the formation of aggressive condensate, which is able to quickly destroy the brick design.

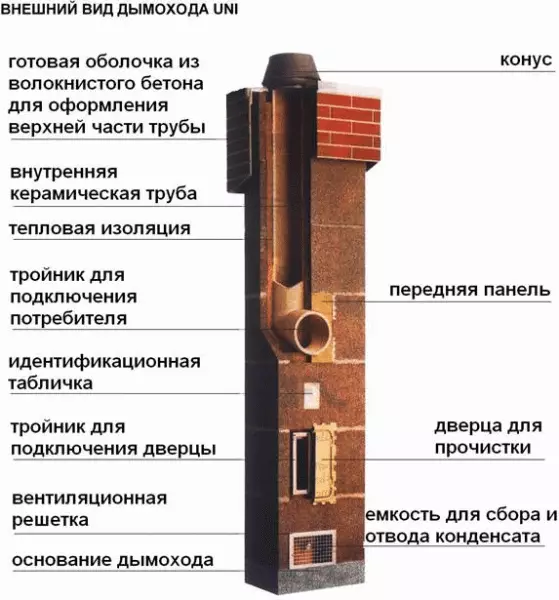

Hood for a boiler from ceramic pipes in a private house

Extract scheme for boiler from ceramic pipes in a private house.

It is worth knowing that the design of ceramic pipes is a universal solution for the boiler in a private house. This is due to the fact that the hoods of special ceramic chimney pipes can be used for all types of boilers. This material is resistant to any chemical aggressive compounds that are able to form in the exhaust in the combustion process of various types of fuel. The material is stable to high temperatures. A similar type of exhaust is the most durable.

Ceramic chimney pipes differ at the maximum permissible temperature of the exhaust gases.

For solid fuel boilers, it is necessary to use pipes that allow the temperature of the exhaust gases in 600-650 ° C. In addition, they must necessarily be resistant to the fire of soot deposits in the pipes and targeted to work in a dry state.

For boilers on liquid fuel and gas boilers, ceramic exhaust systems are used with a permissible gas temperature of 400-450 ° C, which are designed to work in wet state - they must be equipped with condensate.

Ceramic pipe will absorb moisture, and therefore it should be ventilated outside.

The purpose and conditions of such a system are indicated in the documentation attached by the manufacturer.

The round shape and smooth surface of the pipe are able to ensure the stability of the walls to pollution and their convenient cleaning in the future.

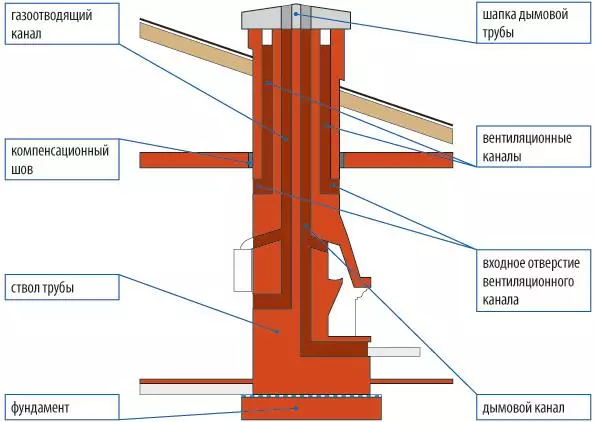

Ceramic exhaust design

Ceramic exhaust design circuit.

Ceramic exhaust pipes are most often placed in a vertical specially laid out channel from building hollow blocks or bricks. The drawing channel can be in the design of the ventilating unit of the available private house.

For masonry, blocks with 1 or 2 emptiness should be applied. In the latter case, the second channel is used to ventilate the boiler room or for air supply to the boiler burner with a closed combustion chamber.

Pipes manufactured design in most cases are insulated to protect the surrounding structures from high temperatures. Around the ceramic pipe for this is a mineral wool insulation. In addition, insulation makes it possible to increase the temperature of the exhaust gases. Cooling in the flue gas pipe can increase the amount of condensate and reduce the natural traction in the pipe.

Article on the topic: how to remove vinyl wallpapers from the wall: to spare old easily, quickly tear off, delete, tear off correctly, photo, video

Between the insulation and the wall of the channel left the air clearance for ventilation of the ceramic pipe and the insulation of the drawing.

To date, the construction market is able to offer sets of materials and parts for the construction of ceramic hoods for boilers in private houses. There are options for the design of ceramic hoods in the steel case - with an outer steel shell. Such a design for its placement will not require the device of special channels in the construction devices of the private house and can be installed completely anywhere, both outside the house and inside it.

Steel hood for boiler in a private house

Pipes for exhaust gas boilers with flue gas temperature of about 400-450 ° C are made of stainless steel, which have a thickness of approximately 0.5-0.6 mm. Such pipes are sufficiently resistant to the effects of aggressive condensate on the walls.Solid fuel boilers use pipes from heat-resistant steel, which have a thickness of 1.0 mm.

The service life of steel hoods is significantly less, and their cost is in most cases higher than brick and ceramic.

However, steel filtering extracts are faster and easier to install, in addition, they have a small weight and do not require special channels and durable grounds for installation in building structures. They are available for repair.

Steel hood for the boiler in its own private house is quite easy to assemble with their own hands from the finished elements. The steel device, as well as ceramic, does not prone to the accumulation of contaminants on the existing walls, and the surface of the walls can be easily cleaned.

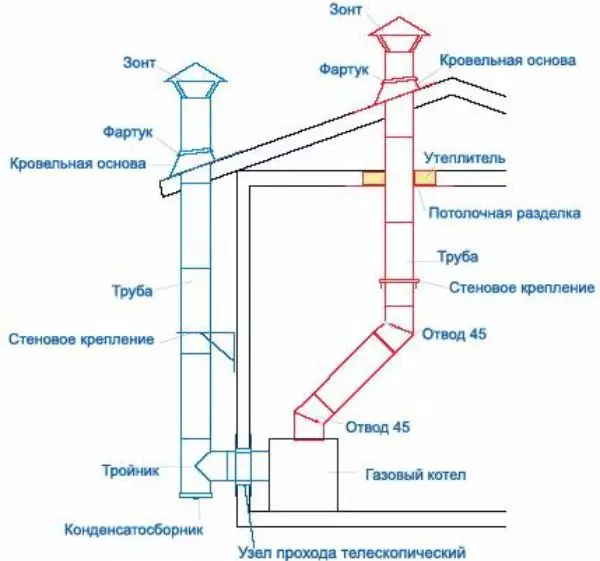

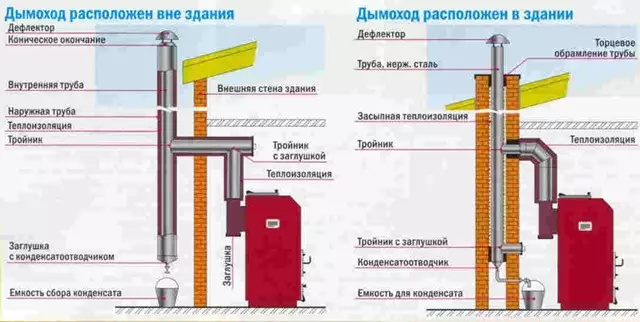

Steel exhaust device

Steel exhaust device diagram.

Steel hoods can be made in several variants:

Single steel pipe made of design can be placed in a vertical specially laid out of the building structure. The exhaust device in this case is similar to the ceramic design.

This option is also used to reconstruct brick hoods, thereby adapting it to work with gas boilers. Single steel pipe can be simply inserted on top of a brick tube channel.

Hood is going from ready-made sections of factory manufacture. Each of the sections is a two-axis sandwich tube. The pipe is made of construction is inside another steel pipe - protective shell, housing. The space between the shell and the pipe is filled with thermal insulation.

Expandments are produced that are intended for installation both outside the premises and inside them. Such a design can be easily assembled from separate sandwich modules. The use of similar devices makes it possible to simply install them in rooms where there are no special chimney channels in building structures. They can be installed and outside on the walls.

For boilers with a closed combustion chamber, air-exhaust steel systems are available - coaxial channels, where one tube is in another. Through the inner tube will be given the flue gases, and the air is supplied to the boiler for burning fuel. The cost of such structures is quite high.

How to make a hood for a boiler in a private house correctly

The scheme of the chimney.

To properly select the hood for the boiler in a private house, you will need to determine the parameters of exhaust flue gases and working conditions. These parameters depend on the type of heating boiler and the type of fuel that is planned to be used.

Article on the topic: How to glue foam ceiling plinth: blowing process (video)

The extractor is selected according to the following parameters:

- On the temperature of exhaust flue gases. The nominal working temperature of the hood should not be less than the temperature of the outgoing gases of the boiler during normal operation.

- On the pressure of gases in the hood. Some designs can be calculated to work with natural thrust (discharge in pipes), others are intended to work with boilers that have a superior to the compulsory allocation of combustion products (overpressure in pipes). Universal extracts on this parameter are available.

- According to the presence of condensate in the hood. Some devices are designed to work in a dry state, under conditions when condensate will not be formed in the pipe. Other constructions are equipped with condensate traps and condensate collectors - capable of working under the conditions of moisture condensation on the walls of the pipes.

- By corrosive resistance. Determined by the content of sulfur in the fuel, which is burned. Such manufactured structures are divided into 3 classes of corrosion resistance to sulfur compounds: 1 class - structures for removing gas combustion products; 2 class - designs for boilers that work on liquid fuel and firewood, with a sulfur content of up to 0.2%; Grade 3 - devices for boilers on the coal, liquid fuel and peat with a sulfur content of no more than 0.2%.

- For resistance to the ignition of the accumulation of soot. Such structures can be resistant or not resistant to the fire of soot. When burning sauhing clusters in the hood, the temperature may increase to 1000 ° C for a short time.

- At the permissible distance to the combustible devices. In the house, the combustible structures should be located from the outer shell of the drawing no longer closer than the distance, which is indicated in the technical documentation for the gas duct, or additionally be protected from the effects of high temperature.

Tips you need to know

Connection diagram to chimney.

An ordinary brick tube, as the most budget option, must be used as an exhaust for ordinary solid fuel boilers that work on firewood. In case, in the future, it is planned to transition to gas fuel, you will need to insert stainless steel liner in the brick tube.

For modern boilers, which operate on gas, liquid fuel, as well as for solid fuel boilers operating on the corner, peat or with a slow combustion regime (pellet, pyrolysis) should be used ceramic chimneys.

Steel chimney is chosen in the case of reconstruction of heating in private homes - when installing boilers in rooms, where there is no channel in building structures to accommodate ceramic chimney.

When using multi-fuel boilers or two boilers, which operate on different types of fuel and connected to a common exhaust, the parameters of such a manufactured design must comply with the stringent working conditions.

It is not allowed to use steel thin-walled hoods that are intended for gas boilers, to work with a solid fuel boiler, because they will run.

Hoods that are intended to work in condensation conditions have the opportunity to work in a dry state, but in no case vice versa.

For boilers that work on solid fuel, extracts are chosen, which are resistant to the fire of soot.

It should be known that the natural ventilation is small-time and is simple, depends on the weather and absolutely no automation. The supply and exhaust forced ventilation has the ability to provide comfortable accommodation conditions, not paying attention to the weather, but for it will have to pay.